All-Inclusive Factory Service Technical manual for OM Pimespo Forklift Trucks Models XD40, XD45 and XD50 (4156 series).

This manuals will assist you in diagnosing, repairing, operating, maintaining, and finding spare parts for your forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

XD40 (4156 series)

XD45 (4156 series)

XD50 (4156 series)

The manual comprises 4 documents, including two Workshop Manuals, the Operate and Maintenance manual, and Parts Catalog

1. Workshop Manual (33_1_1850_1_en)

Format: PDF, 270 pages

Language: English

2. Workshop Manual (XD40-50_41568042301_Ed_03-2006_EN)

Format: PDF, 270 pages

Language: English

3. Operate and Maintenance manual (XD40-50_41568042501_102007_EN)

Format: PDF, 178 pages

Language: English

Table of Contents:

Summary Data for Technical Assistance

Introduction

General Information

Normative References

Areas with risk of explosion and handling of explosive loads.

Type of use and contraindications for use

Use Limitations

Driving on public roads

General Forklift Description

Equipment Assembly

Modifications to Forklift

Forklift Delivery

Safety

Safety regulations

Safety regulations in case of accidental lateral tipping

Flooring requirements

Safety Regulations Relative to Forklift Use

Safety Regulations Relative to Operating Materials

Safety regulations during tyre inflation

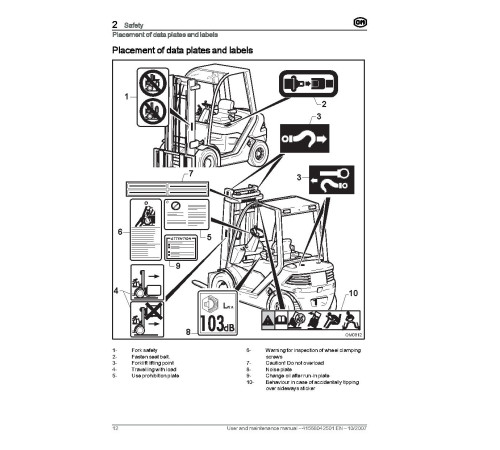

Placement of data plates and labels

Description of data plates and labels

Safety features

Noise

Electromagnetic Compliance

Vibrations

Engine emissions

Knowledge of the Forklift

General forklift view

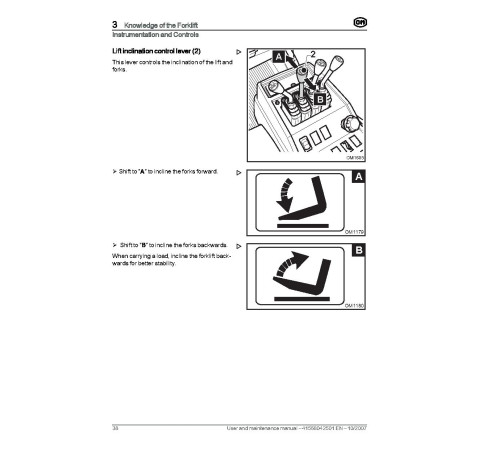

Instrumentation and Controls

Internal parts

Forklift identification

Optional list

Use and Operation

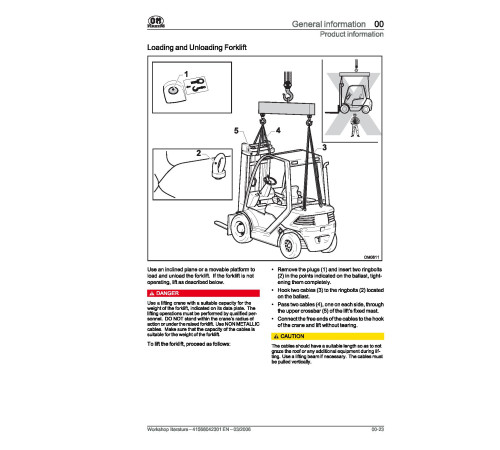

Forklift Transport and Lifting

Commissioning

Running-In

Daily checks before use

Wheel Tightening Check

Tyre pressure check

Chain tension check

Hydraulic distribution linkage inspection

Particulate filter inspection and condensation draining procedure (optional)

Coolant level checking procedure

Transmission oil level inspection procedure

Check axle oil level

Engine oil level checking procedure

Refuelling

Use of truck

Load Placement

Towing trailers

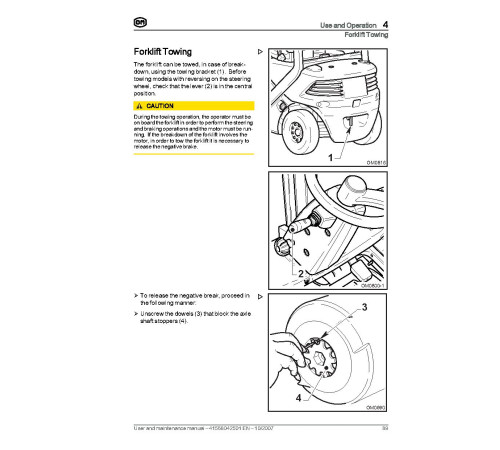

Forklift Towing

Particulate filter regeneration procedure (optional)

General Information

Operations Preliminary to Maintenance

Maintenance

Maintenance as required

Maintenance to be performed after running-in

Scheduled Maintenance

Synoptic table of general maintenance operations on the forklift

Every 500 hours

Engine service schedule

Every 500 hours

Putting out of Commission

Supply Table

Overall dimensions

Technical Data

Abbreviations key

Alternative lift characteristics

Fork lift truck capacities - Model 40 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 40 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Fork lift truck capacities - Model 45 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 45 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Fork lift truck capacities - Model 50 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 50 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Tyre characteristics

Gradients

Pneumatic tyre inflation pressure

Lamps

Annex

Hydraulic equipment diagram

Hydraulic diagram

Functional diagram

Electric circuit diagram (lights functional diagram)

4. Parts Catalog (424_1552751118890_en)

Format: PDF, 620 pages

Language: English

Table of Contents:

XD40-50 (2010-08)

CHASSIS

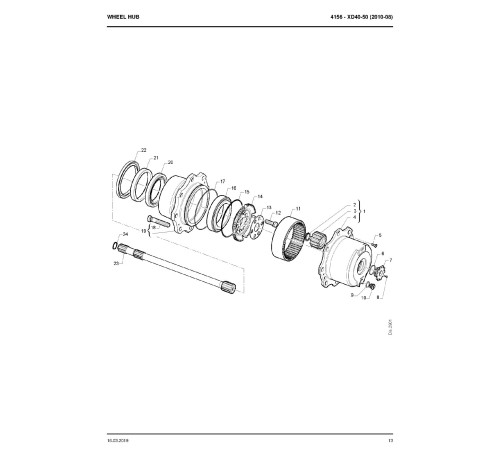

GEAR DRIVE

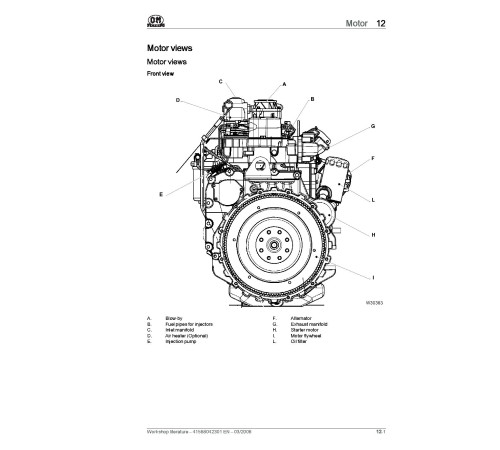

IC ENGINE/ MOTOR

CONNECTION PARTS

ENGINE TRANSMISSION CONNECTION

FUEL TANK

TILT CYLINDER

ACCELERATOR LINKAGE

ACCELERATOR PEDAL

PIPE EXHAUST

VALVE BLOCK

radiator

AIR FILTER

SINGLE SUPERELASTIC WHEELS

Einzelreifen

TWIN PNEUMATIC WHEELS

TWIN SUPERELASTIC WHEELS

CHASSIS

tow coupling

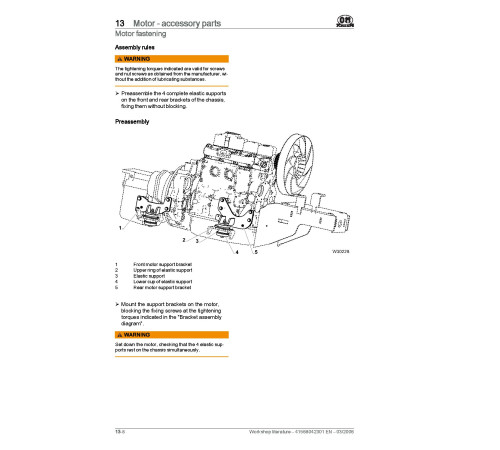

ENGINE SUSPENSIONS

REAR AXLE

POWER STEER CYLINDER

POWER STEERING

POWER STEERING DISTRIBUTOR

POWER STEERING

PARKING BRAKE

BRAKING SYSTEM

BRAKE PEDAL - INCHING

BRAKE - ACCUMULATOR

BRAKE OIL COOLING

ELECTRIC INSTRUMENTS

BATTERY

rear light

oil tank

oil filter

POWER STEERING HYDRAULIC SYSTEM

HYDRAULIC SYSTEM - OIL PUMP

TRAVERSE HYDRAULIC SYSTEM

POWER STEERING HYDRAULIC SYSTEM

HYDRAULIC SYSTEM - OIL PUMP

HYDRAULIC SYSTEM - BRAKES

OIL PUMP

DISTRIBUTOR CONTROLS

DISTRIBUTOR LEVERS

ELEMENT DISTRIBUTOR

DISTRIBUTOR CONTROLS

DISTRIBUTOR LEVERS

ELEMENT DISTRIBUTOR

ELEMENT SERVO-CONTROL

OIL PRESSURE VALVE

HOOD

COVERS

DRIVER

SEAT

STICKER

LABEL

CATALOG

HUBVORRICHTUNG

STRUCTURE (SIMPLEX)

SIMPLEX 4-ROLLER FORK CARRIAGE

SIMPLEX 6-ROLLER FORK CARRIAGE

SIMPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (SIMPLEX)

SIMPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (SIMPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (SIMPLEX)

STRUCTURE (DUPLEX)

DUPLEX A ROLLER FORK CARRIAGE

DUPLEX 6-ROLLER FORK CARRIAGE

DUPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (DUPLEX)

DUPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

LEFT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

STRUCTURE (TRIPLEX)

TRIPLEX 4 ROLLER FORK CARRIAGE

TRIPLEX 6-ROLLER FORK CARRIAGE

TRIPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (TRIPLEX)

TRIPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (TRIPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (TRIPLEX)

options

WORKING LIGHTS

WORKING LIGHTS + FLASHER

rd WORKING LIGHT + FLASHER

KILN KIT

rd WORKING LIGHT

SEAT HEATER

heated seat

HYDRAULIC HOSING

HYDRAULIC OPERATING SYSTEM

CEILING LIGHT

soot filter

PVC SEAT

REARVIEW MIRRORS FOR CLOSED CABIN

THREE ELEMENTS DISTRIBUTOR LEVER LOCK

ELEMENT DISTRIBUTOR CONTROLS FOR LEVER LOCKING

DISTRIBUTOR LEVER LOCK

FOUR ELEMENTS DISTRIBUTOR LEVER LOCK

ELEMENT DISTRIBUTOR CONTROLS FOR LEVER LOCKING

GABELABDECKUNG

RAISED DRIVER'S SEAT - EXHAUST PIPES

RAISED DRIVER'S SEAT - AIR FILTER

RAISED DRIVER'S SEAT - PARKING BRAKE

RAISED DRIVER'S SEAT - ACCUMULATOR

RAISED DRIVER'S SEAT - INCHING BRAKE PEDAL

RAISED DRIVER'S SEAT - ELECTRIC SYSTEM

RAISED DRIVER'S SEAT - HYDRAULIC SYSTEM

RAISED DRIVER'S SEAT - DISTRIBUTOR CONTROLS

RAISED DRIVER'S SEAT - DISTRIBUTOR LEVERS

raised driver's seat

ROLL BAR

REARVIEW MIRRORS

air conditioning

compressor

comfortable cabin

SOUNDPROOF CABIN

DIRECTION INVERTER

ANTI-SPARK SILENCER

CATALYTIC SILENCER

CYCLONE FILTER

DUSTY ENVIROMENTS

NON-TOXIC SUPERELASTIC WHEELS

NON-TOXIC SUPERELASTIC TWIN WHEELS

LIGHT SYSTEM

NUMBER PLATE LIGHT

LAMP

DRIVER (MSG20)

fabric seat

DRIVER (MSG85)

TWING WORK LIGHTS

LOWERED ROOF

DRIVER (abgesenkte Fahrerkabine)

SEAT FOR LOWERED ROOF

EXHAUST PIPE FOR LOWERED ROOF

PROTECTIVE STEEL CABIN

STEEL DOOR

PROTECTIVE STEEL CABIN

STEEL DOOR

SOUNDPROOF CABIN

HEATING SYSTEM (OPTIONAL)

CAB HEATING

ROAD HOMOLOGATION

fork carriage

FRONT + REAR WITH DEFROST

SUN VISOR

ELEMENT DISTIBUTOR

ELEMENT SERVO-CONTROL

th LINE

FORK

PVC DOOR

EQUIPMENT HYDRAULIC SYSTEM

index parts

This manuals will assist you in diagnosing, repairing, operating, maintaining, and finding spare parts for your forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

XD40 (4156 series)

XD45 (4156 series)

XD50 (4156 series)

The manual comprises 4 documents, including two Workshop Manuals, the Operate and Maintenance manual, and Parts Catalog

1. Workshop Manual (33_1_1850_1_en)

Format: PDF, 270 pages

Language: English

2. Workshop Manual (XD40-50_41568042301_Ed_03-2006_EN)

Format: PDF, 270 pages

Language: English

3. Operate and Maintenance manual (XD40-50_41568042501_102007_EN)

Format: PDF, 178 pages

Language: English

Table of Contents:

Summary Data for Technical Assistance

Introduction

General Information

Normative References

Areas with risk of explosion and handling of explosive loads.

Type of use and contraindications for use

Use Limitations

Driving on public roads

General Forklift Description

Equipment Assembly

Modifications to Forklift

Forklift Delivery

Safety

Safety regulations

Safety regulations in case of accidental lateral tipping

Flooring requirements

Safety Regulations Relative to Forklift Use

Safety Regulations Relative to Operating Materials

Safety regulations during tyre inflation

Placement of data plates and labels

Description of data plates and labels

Safety features

Noise

Electromagnetic Compliance

Vibrations

Engine emissions

Knowledge of the Forklift

General forklift view

Instrumentation and Controls

Internal parts

Forklift identification

Optional list

Use and Operation

Forklift Transport and Lifting

Commissioning

Running-In

Daily checks before use

Wheel Tightening Check

Tyre pressure check

Chain tension check

Hydraulic distribution linkage inspection

Particulate filter inspection and condensation draining procedure (optional)

Coolant level checking procedure

Transmission oil level inspection procedure

Check axle oil level

Engine oil level checking procedure

Refuelling

Use of truck

Load Placement

Towing trailers

Forklift Towing

Particulate filter regeneration procedure (optional)

General Information

Operations Preliminary to Maintenance

Maintenance

Maintenance as required

Maintenance to be performed after running-in

Scheduled Maintenance

Synoptic table of general maintenance operations on the forklift

Every 500 hours

Engine service schedule

Every 500 hours

Putting out of Commission

Supply Table

Overall dimensions

Technical Data

Abbreviations key

Alternative lift characteristics

Fork lift truck capacities - Model 40 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 40 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Fork lift truck capacities - Model 45 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 45 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Fork lift truck capacities - Model 50 - Masts vertical with fork arms = 1400 mm max. (for pneumatic tyres)

Fork lift truck capacities - Model 50 - Masts vertical with fork arms = 1400 mm max. (for superelastic tyres)

Tyre characteristics

Gradients

Pneumatic tyre inflation pressure

Lamps

Annex

Hydraulic equipment diagram

Hydraulic diagram

Functional diagram

Electric circuit diagram (lights functional diagram)

4. Parts Catalog (424_1552751118890_en)

Format: PDF, 620 pages

Language: English

Table of Contents:

XD40-50 (2010-08)

CHASSIS

GEAR DRIVE

IC ENGINE/ MOTOR

CONNECTION PARTS

ENGINE TRANSMISSION CONNECTION

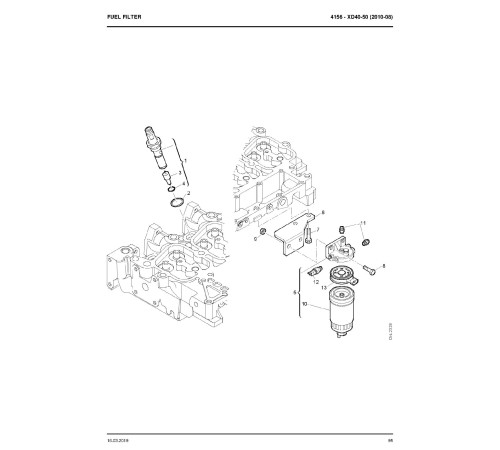

FUEL TANK

TILT CYLINDER

ACCELERATOR LINKAGE

ACCELERATOR PEDAL

PIPE EXHAUST

VALVE BLOCK

radiator

AIR FILTER

SINGLE SUPERELASTIC WHEELS

Einzelreifen

TWIN PNEUMATIC WHEELS

TWIN SUPERELASTIC WHEELS

CHASSIS

tow coupling

ENGINE SUSPENSIONS

REAR AXLE

POWER STEER CYLINDER

POWER STEERING

POWER STEERING DISTRIBUTOR

POWER STEERING

PARKING BRAKE

BRAKING SYSTEM

BRAKE PEDAL - INCHING

BRAKE - ACCUMULATOR

BRAKE OIL COOLING

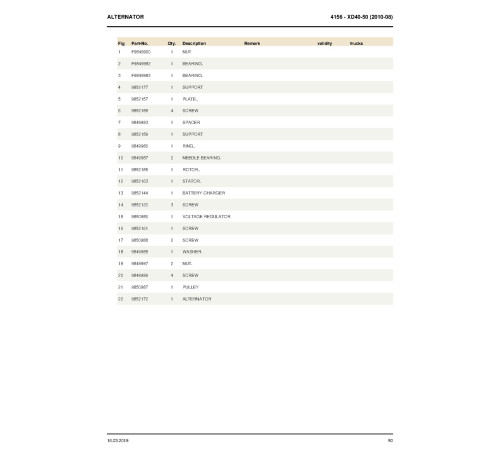

ELECTRIC INSTRUMENTS

BATTERY

rear light

oil tank

oil filter

POWER STEERING HYDRAULIC SYSTEM

HYDRAULIC SYSTEM - OIL PUMP

TRAVERSE HYDRAULIC SYSTEM

POWER STEERING HYDRAULIC SYSTEM

HYDRAULIC SYSTEM - OIL PUMP

HYDRAULIC SYSTEM - BRAKES

OIL PUMP

DISTRIBUTOR CONTROLS

DISTRIBUTOR LEVERS

ELEMENT DISTRIBUTOR

DISTRIBUTOR CONTROLS

DISTRIBUTOR LEVERS

ELEMENT DISTRIBUTOR

ELEMENT SERVO-CONTROL

OIL PRESSURE VALVE

HOOD

COVERS

DRIVER

SEAT

STICKER

LABEL

CATALOG

HUBVORRICHTUNG

STRUCTURE (SIMPLEX)

SIMPLEX 4-ROLLER FORK CARRIAGE

SIMPLEX 6-ROLLER FORK CARRIAGE

SIMPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (SIMPLEX)

SIMPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (SIMPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (SIMPLEX)

STRUCTURE (DUPLEX)

DUPLEX A ROLLER FORK CARRIAGE

DUPLEX 6-ROLLER FORK CARRIAGE

DUPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (DUPLEX)

DUPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

LEFT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (DUPLEX)

STRUCTURE (TRIPLEX)

TRIPLEX 4 ROLLER FORK CARRIAGE

TRIPLEX 6-ROLLER FORK CARRIAGE

TRIPLEX HYDRAULIC SYSTEM

ROLLER SIDESHIFT PLATE (TRIPLEX)

TRIPLEX S.L.I. HYDRAULIC SYSTEM

LEFT ADDITIONAL HYDRAULIC SYSTEM (TRIPLEX)

RIGHT ADDITIONAL HYDRAULIC SYSTEM (TRIPLEX)

options

WORKING LIGHTS

WORKING LIGHTS + FLASHER

rd WORKING LIGHT + FLASHER

KILN KIT

rd WORKING LIGHT

SEAT HEATER

heated seat

HYDRAULIC HOSING

HYDRAULIC OPERATING SYSTEM

CEILING LIGHT

soot filter

PVC SEAT

REARVIEW MIRRORS FOR CLOSED CABIN

THREE ELEMENTS DISTRIBUTOR LEVER LOCK

ELEMENT DISTRIBUTOR CONTROLS FOR LEVER LOCKING

DISTRIBUTOR LEVER LOCK

FOUR ELEMENTS DISTRIBUTOR LEVER LOCK

ELEMENT DISTRIBUTOR CONTROLS FOR LEVER LOCKING

GABELABDECKUNG

RAISED DRIVER'S SEAT - EXHAUST PIPES

RAISED DRIVER'S SEAT - AIR FILTER

RAISED DRIVER'S SEAT - PARKING BRAKE

RAISED DRIVER'S SEAT - ACCUMULATOR

RAISED DRIVER'S SEAT - INCHING BRAKE PEDAL

RAISED DRIVER'S SEAT - ELECTRIC SYSTEM

RAISED DRIVER'S SEAT - HYDRAULIC SYSTEM

RAISED DRIVER'S SEAT - DISTRIBUTOR CONTROLS

RAISED DRIVER'S SEAT - DISTRIBUTOR LEVERS

raised driver's seat

ROLL BAR

REARVIEW MIRRORS

air conditioning

compressor

comfortable cabin

SOUNDPROOF CABIN

DIRECTION INVERTER

ANTI-SPARK SILENCER

CATALYTIC SILENCER

CYCLONE FILTER

DUSTY ENVIROMENTS

NON-TOXIC SUPERELASTIC WHEELS

NON-TOXIC SUPERELASTIC TWIN WHEELS

LIGHT SYSTEM

NUMBER PLATE LIGHT

LAMP

DRIVER (MSG20)

fabric seat

DRIVER (MSG85)

TWING WORK LIGHTS

LOWERED ROOF

DRIVER (abgesenkte Fahrerkabine)

SEAT FOR LOWERED ROOF

EXHAUST PIPE FOR LOWERED ROOF

PROTECTIVE STEEL CABIN

STEEL DOOR

PROTECTIVE STEEL CABIN

STEEL DOOR

SOUNDPROOF CABIN

HEATING SYSTEM (OPTIONAL)

CAB HEATING

ROAD HOMOLOGATION

fork carriage

FRONT + REAR WITH DEFROST

SUN VISOR

ELEMENT DISTIBUTOR

ELEMENT SERVO-CONTROL

th LINE

FORK

PVC DOOR

EQUIPMENT HYDRAULIC SYSTEM

index parts

Included

Workshop Manual

2Operate and Maintenance manual

1Parts Catalog

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары