$49.99

Fault Codes List

1Service Manual

13Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

1Illustrated factory set of Service Manuals for Mitsubishi Pallet Stackers Models SBS15N, SBS15NI and SBS20N.

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your pallet stacker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

SBS15N

SBS15NI

SBS20N

The manual comprises 18 documents, including the Fault Codes List, 13 Service Manuals, Operate and Maintenance manual, two Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List (FC-SBS15N)

Format: PDF, 34 pages

Language: English

Table of Contents:

1.1 Traction motor controller (Combi Ac1) Mode:2

1.2 Pump motor controller (Combi Ac1) (Mode:5)

1.3 Electric power steering controller (EPS) Mode:6

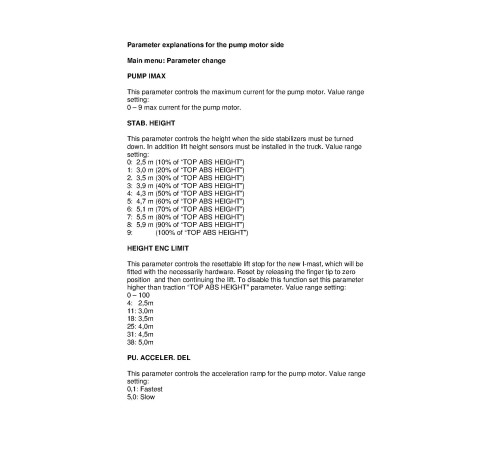

2. Service Manual: Parameter explanations for the pump motor (PA-Pump_motor)

Format: PDF, 7 pages

Language: English

Table of Contents:

Main menu: Parameter change

PUMP IMAX

STAB. HEIGHT

HEIGHT ENC LIMIT

PU. ACCELER. DEL

PU. DECELER. DEL

LIFT SPEED

CREEP SPEED

1ST SPEED FINE

1ST SPEED COMP.

2ND SPEED FINE

2ND SPEED COMP.

3RD SPEED FINE

3RD SPEED COMP.

COMPENSATION

CUTBAC SPEED

MIN EVP

MAX EVP

MIN LIFT EVP

MAX LIFT EVP

MIN EV1

MAX EV1

EVP OPEN DELAY

EVP CLOSE DELAY

EVP CL. DEL RED

EVP1 OPEN DELAY

EVP1 CLOSE DELAY

START LOWER RED.

DUAL PUMP DELAY

Submenu: CONFIG MENU / SET MODEL

MODEL TYPE

Submenu: SET OPTIONS

HOUR COUNTER

EVP TYPE

EV1 TYPE

SET TEMPERATURE

SIDE STABILIZER

AUX OUTPUT #6

AUX OUTPUT #5

DUAL PUMP

SET INPUT #2

Submenu: ADJUSTMENTS

FAN TEMPERATURE

THROTTLE 0 POINT

THROTTLE X POINT

THROTTLE Y POINT

Submenu: SPECIAL ADJUST

3. Service Manual: Curtis display (SM-Curtis_display)

Format: PDF, 13 pages

Language: English

4. Service Manual: Parameter explanations for the EPS (PA-EPS)

Format: PDF, 10 pages

Language: English

5. Service Manual: Parameters: Pump Controller ro045_SBS15N,SBS20N (PA-Pump_Controller_ro045)

Format: PDF, 3 pages

Language: English

6. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

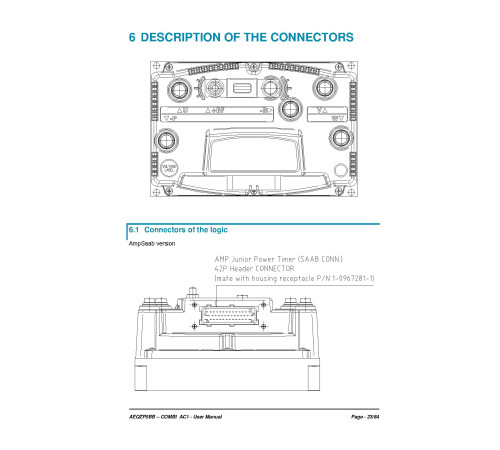

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

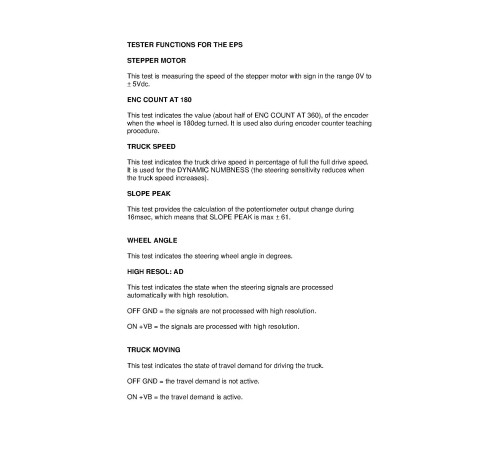

7. Service Manual: TESTER FUNCTIONS FOR THE EPS (PA-Test_EPS_SBS15N,SBS20N)

Format: PDF, 4 pages

Language: English

Table of Contents:

STEPPER MOTOR

ENC COUNT AT 180

TRUCK SPEED

SLOPE PEAK

WHEEL ANGLE

HIGH RESOL: AD

TRUCK MOVING

SM ALARM SWITCH

MM ALARM SWITCH

AUTO IN PROGRESS

ACW LIMIT LEVEL

CW LIMIT LEVEL

END STROKE ACW

END STROKE CW

ENC SPEED

MOTOR CURRENT

MOTOR VOLTAGE

SAT FREQ HZ

FREQUENCY

MOTOR TEMPERAT.

TEMPERATURE

FEEDBACK ENC.

FEEDBACK SECTOR

8. Service Manual: TESTER FUNCTIONS FOR THE PUMP CONTROLLER (PA-Test_Pump_controller_SBS15N,SBS20N)

Format: PDF, 5 pages

Language: English

Table of Contents:

MOTOR CURRENT

EV7

EV6

EV5

EV4

EV3

EV2

EV1

SET POINT EVP

HORN SWITCH

DIGITAL INPUT #9

STAB UP INPUT

STAB DOWN INPUT

DIGITAL INPUT #7

DIGITAL INPUT #6

DIGITAL INPUT #5

DIGITAL INPUT #4

DIGITAL INPUT #3

DIGITAL INPUT #2

DIGITAL INPUT #1

HANDLE/SEAT SW.

LIFTING CONTROL

ACCELERATOR

MOTOR TEMPERAT.

SLIP

ENCODER

MOTOR POWER

MOTOR VOLTAGE

9. Service Manual: TESTER FUNCTIONS FOR THE TRACTION CONTROLLER (PA-Test_traction_controller_SBS15N,SBS20N)

Format: PDF, 5 pages

Language: English

Table of Contents:

BATTERY VOLTAGE

ANGLE SECTOR

STEER ANGLE

SIDE STAB UP M

LIFTING CUTOUT

SIDE STAB DW M

IN7 SWITCH

SAFETY PEDAL

IN5 SWITCH

STOP FROM EPS

HANDLE/SEAT SWITCH

BACKWARD SWITCH

FORWARD SWITCH

CUTBACK SWITCH 2

CUTBACK SWITCH

DESCENT SWITCH

TILLER SWITCH

ACCELERATOR

WEIGHT

LOAD SENSOR

MOTOR TEMPERAT.

TEMPERATURE

BATTERY CHARGE

CURRENT RMS

SLIP VALUE

ENCODER

FREQUENCY

VOLTAGE BOOSTER

MOTOR VOLTAGE

10. Service Manual: Testing the truck with the console (PA-Test_truck)

Format: PDF, 14 pages

Language: English

Table of Contents:

1.1 Traction motor controller (Combi Ac1) Mode:2

1.2 Pump motor controller (Combi Ac1) Mode:5

1.3 Electric power steering controller (EPS) Mode:6

11. Service Manual: Parameters: Traction Controllers (PA-Traction_motor)

Format: PDF, 13 pages

Language: English

Table of Contents:

Main menu: Parameter change

ACCELER. DELAY

RELEASE BRAKING

TILLER BRAKING

INVERS. BRAKING

DECEL. BRAKING

LOAD ACCEL DEL.

LOAD REL BRAKING

LOAD TIL BRAKING

LOAD INV BRAK.

SPEED LIMIT BRK.

MAX SPEED FORW

MAX SPEED BACK

MAX SPD LOAD FORW.

MAX SPD LOAD REV

CUTBACK SPEED 1

CUTBACK SPEED 2

CURVE CUTBACK

STEER DEAD ANGLE

FREQUENCY CREEP

MAXIMUM CURRENT

ACC SMOTH

INV SMOOTH

STOP SMOOTH

BRK SMOOTH

STOP BRK SMOOTH

LOAD SMOOTH ACC

LOAD INV SMOOTH

LOAD STOP SMOOTH

MAX LOAD WEIGHT

AUXILIARY TIME

TOP ABS HEIGHT

HEIGHT REDUCTION

AUX FUNCTION #7

Ssubmenu: SET OPTIONS

TILLER SWITCH

HOUR COUNTER

BATTERY CHECK

STOP ON RAMP

AUX OUTPUT #1

SET MOT. TEMPERAT

QUICK INVERSION

CAN ENCODER

INVERSION MODE

BEAN PANEL

DISPLAY

LOAD SENSOR

AUX INPUT #1

AUX INPUT #6

SEAT LEVEL

TRUCK DIRECTION

ANG OFFSET

Submenu: SET MODEL

CONNECTED TO

Submenu: ADJUSTMENTS

SET BATTERY TYPE

ADJUST BATTERY

ADJ MIN LOAD

ADJ MAX LOAD

SET ACCELER. MIN

SET ACCELER. MAX

SET ACC. MIN REV

SET ACC. MAX REV

SET MIN LIFT

SET MAX LIFT

SET MIN LOWER

SET MAX LOWER

THROTTLE 0 ZONE

THROTTLE X POINT

THROTTLE Y POINT

BAT MIN ADJ.

BAT MAX ADJ.

MAIN CONT. VOLT

AUX OUTPUT VOLT

Submenu: SPECIAL ADJUSTMENT

ADJUSTMENT #01

ADJUSTMENT #02

SET CURRENT

SET TEMPERATURE

HIGH ADDRESS

Submenu: HARDWARE SETTINGS

TOP MAX SPEED

TOP MAX SPEED R

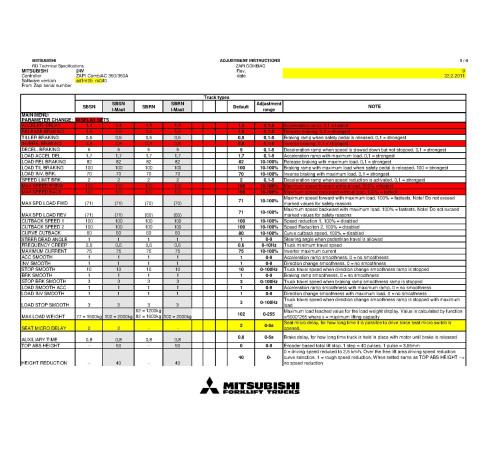

12. Service Manual: Parameters (PA-TR-SBS15N_SBS20_220211)

Format: PDF, 4 pages

Language: English

13. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

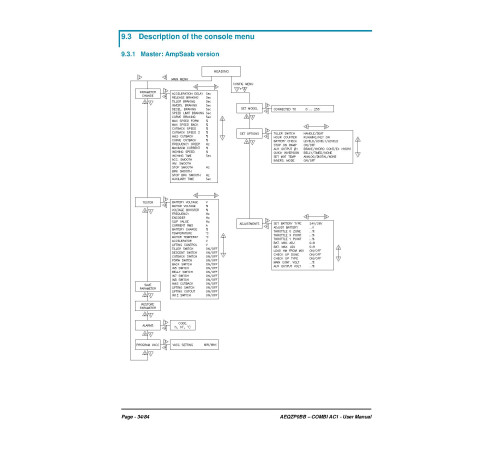

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

14. Service Manual: Parameters: Steer controller EPS RO.90 (PA-EPS_RO.90_63885)

Format: PDF, 2 pages

Language: English

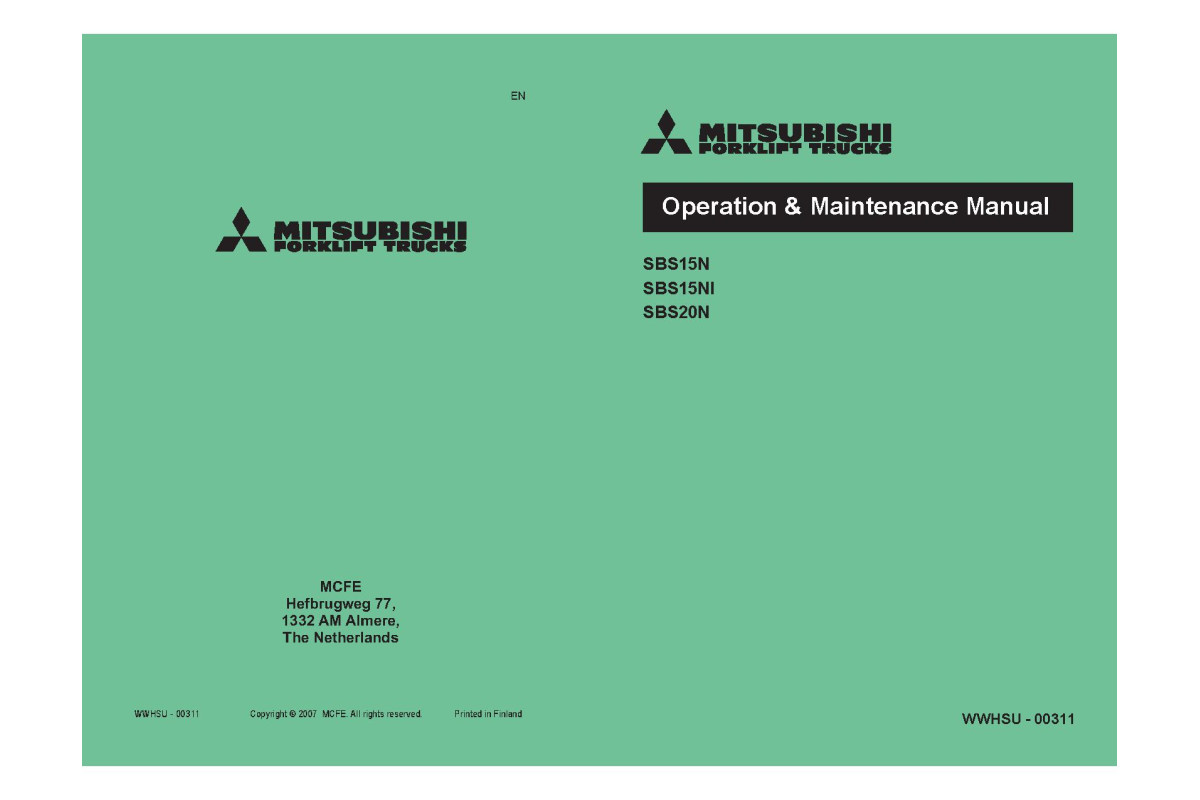

15. Operate and Maintenance manual (OMM-WWHSU-00311)

Format: PDF, 42 pages

Language: English

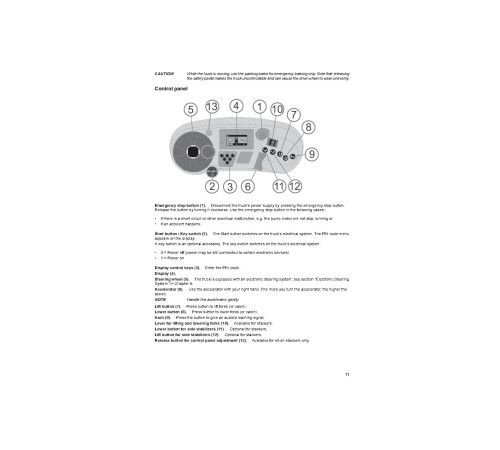

Table of Contents:

Truck

Safety instructions

Operating environment

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

16. Wiring Diagram (EL-TS1141211_G)

Format: PDF, 10 pages

Language: English

Table of Contents:

3-6968: NSS15N,NSS20N

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 2

5: STEERING CIRCUIT

6: DISPLAY AND CONTROL CIRCUITS

7: HYDRAULICS, AUX. DEVICES

8: AUX. DEVICES

9: COLD STORAGE

10: INSTR. PANEL GROUNDING

17. Wiring Diagram (EL-TS1150908_RevE)

Language: English

18. Hydraulic Circuit Diagram (HY-TH79_0707)

Format: PDF, 1 page

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your pallet stacker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

SBS15N

SBS15NI

SBS20N

The manual comprises 18 documents, including the Fault Codes List, 13 Service Manuals, Operate and Maintenance manual, two Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List (FC-SBS15N)

Format: PDF, 34 pages

Language: English

Table of Contents:

1.1 Traction motor controller (Combi Ac1) Mode:2

1.2 Pump motor controller (Combi Ac1) (Mode:5)

1.3 Electric power steering controller (EPS) Mode:6

2. Service Manual: Parameter explanations for the pump motor (PA-Pump_motor)

Format: PDF, 7 pages

Language: English

Table of Contents:

Main menu: Parameter change

PUMP IMAX

STAB. HEIGHT

HEIGHT ENC LIMIT

PU. ACCELER. DEL

PU. DECELER. DEL

LIFT SPEED

CREEP SPEED

1ST SPEED FINE

1ST SPEED COMP.

2ND SPEED FINE

2ND SPEED COMP.

3RD SPEED FINE

3RD SPEED COMP.

COMPENSATION

CUTBAC SPEED

MIN EVP

MAX EVP

MIN LIFT EVP

MAX LIFT EVP

MIN EV1

MAX EV1

EVP OPEN DELAY

EVP CLOSE DELAY

EVP CL. DEL RED

EVP1 OPEN DELAY

EVP1 CLOSE DELAY

START LOWER RED.

DUAL PUMP DELAY

Submenu: CONFIG MENU / SET MODEL

MODEL TYPE

Submenu: SET OPTIONS

HOUR COUNTER

EVP TYPE

EV1 TYPE

SET TEMPERATURE

SIDE STABILIZER

AUX OUTPUT #6

AUX OUTPUT #5

DUAL PUMP

SET INPUT #2

Submenu: ADJUSTMENTS

FAN TEMPERATURE

THROTTLE 0 POINT

THROTTLE X POINT

THROTTLE Y POINT

Submenu: SPECIAL ADJUST

3. Service Manual: Curtis display (SM-Curtis_display)

Format: PDF, 13 pages

Language: English

4. Service Manual: Parameter explanations for the EPS (PA-EPS)

Format: PDF, 10 pages

Language: English

5. Service Manual: Parameters: Pump Controller ro045_SBS15N,SBS20N (PA-Pump_Controller_ro045)

Format: PDF, 3 pages

Language: English

6. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

7. Service Manual: TESTER FUNCTIONS FOR THE EPS (PA-Test_EPS_SBS15N,SBS20N)

Format: PDF, 4 pages

Language: English

Table of Contents:

STEPPER MOTOR

ENC COUNT AT 180

TRUCK SPEED

SLOPE PEAK

WHEEL ANGLE

HIGH RESOL: AD

TRUCK MOVING

SM ALARM SWITCH

MM ALARM SWITCH

AUTO IN PROGRESS

ACW LIMIT LEVEL

CW LIMIT LEVEL

END STROKE ACW

END STROKE CW

ENC SPEED

MOTOR CURRENT

MOTOR VOLTAGE

SAT FREQ HZ

FREQUENCY

MOTOR TEMPERAT.

TEMPERATURE

FEEDBACK ENC.

FEEDBACK SECTOR

8. Service Manual: TESTER FUNCTIONS FOR THE PUMP CONTROLLER (PA-Test_Pump_controller_SBS15N,SBS20N)

Format: PDF, 5 pages

Language: English

Table of Contents:

MOTOR CURRENT

EV7

EV6

EV5

EV4

EV3

EV2

EV1

SET POINT EVP

HORN SWITCH

DIGITAL INPUT #9

STAB UP INPUT

STAB DOWN INPUT

DIGITAL INPUT #7

DIGITAL INPUT #6

DIGITAL INPUT #5

DIGITAL INPUT #4

DIGITAL INPUT #3

DIGITAL INPUT #2

DIGITAL INPUT #1

HANDLE/SEAT SW.

LIFTING CONTROL

ACCELERATOR

MOTOR TEMPERAT.

SLIP

ENCODER

MOTOR POWER

MOTOR VOLTAGE

9. Service Manual: TESTER FUNCTIONS FOR THE TRACTION CONTROLLER (PA-Test_traction_controller_SBS15N,SBS20N)

Format: PDF, 5 pages

Language: English

Table of Contents:

BATTERY VOLTAGE

ANGLE SECTOR

STEER ANGLE

SIDE STAB UP M

LIFTING CUTOUT

SIDE STAB DW M

IN7 SWITCH

SAFETY PEDAL

IN5 SWITCH

STOP FROM EPS

HANDLE/SEAT SWITCH

BACKWARD SWITCH

FORWARD SWITCH

CUTBACK SWITCH 2

CUTBACK SWITCH

DESCENT SWITCH

TILLER SWITCH

ACCELERATOR

WEIGHT

LOAD SENSOR

MOTOR TEMPERAT.

TEMPERATURE

BATTERY CHARGE

CURRENT RMS

SLIP VALUE

ENCODER

FREQUENCY

VOLTAGE BOOSTER

MOTOR VOLTAGE

10. Service Manual: Testing the truck with the console (PA-Test_truck)

Format: PDF, 14 pages

Language: English

Table of Contents:

1.1 Traction motor controller (Combi Ac1) Mode:2

1.2 Pump motor controller (Combi Ac1) Mode:5

1.3 Electric power steering controller (EPS) Mode:6

11. Service Manual: Parameters: Traction Controllers (PA-Traction_motor)

Format: PDF, 13 pages

Language: English

Table of Contents:

Main menu: Parameter change

ACCELER. DELAY

RELEASE BRAKING

TILLER BRAKING

INVERS. BRAKING

DECEL. BRAKING

LOAD ACCEL DEL.

LOAD REL BRAKING

LOAD TIL BRAKING

LOAD INV BRAK.

SPEED LIMIT BRK.

MAX SPEED FORW

MAX SPEED BACK

MAX SPD LOAD FORW.

MAX SPD LOAD REV

CUTBACK SPEED 1

CUTBACK SPEED 2

CURVE CUTBACK

STEER DEAD ANGLE

FREQUENCY CREEP

MAXIMUM CURRENT

ACC SMOTH

INV SMOOTH

STOP SMOOTH

BRK SMOOTH

STOP BRK SMOOTH

LOAD SMOOTH ACC

LOAD INV SMOOTH

LOAD STOP SMOOTH

MAX LOAD WEIGHT

AUXILIARY TIME

TOP ABS HEIGHT

HEIGHT REDUCTION

AUX FUNCTION #7

Ssubmenu: SET OPTIONS

TILLER SWITCH

HOUR COUNTER

BATTERY CHECK

STOP ON RAMP

AUX OUTPUT #1

SET MOT. TEMPERAT

QUICK INVERSION

CAN ENCODER

INVERSION MODE

BEAN PANEL

DISPLAY

LOAD SENSOR

AUX INPUT #1

AUX INPUT #6

SEAT LEVEL

TRUCK DIRECTION

ANG OFFSET

Submenu: SET MODEL

CONNECTED TO

Submenu: ADJUSTMENTS

SET BATTERY TYPE

ADJUST BATTERY

ADJ MIN LOAD

ADJ MAX LOAD

SET ACCELER. MIN

SET ACCELER. MAX

SET ACC. MIN REV

SET ACC. MAX REV

SET MIN LIFT

SET MAX LIFT

SET MIN LOWER

SET MAX LOWER

THROTTLE 0 ZONE

THROTTLE X POINT

THROTTLE Y POINT

BAT MIN ADJ.

BAT MAX ADJ.

MAIN CONT. VOLT

AUX OUTPUT VOLT

Submenu: SPECIAL ADJUSTMENT

ADJUSTMENT #01

ADJUSTMENT #02

SET CURRENT

SET TEMPERATURE

HIGH ADDRESS

Submenu: HARDWARE SETTINGS

TOP MAX SPEED

TOP MAX SPEED R

12. Service Manual: Parameters (PA-TR-SBS15N_SBS20_220211)

Format: PDF, 4 pages

Language: English

13. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

14. Service Manual: Parameters: Steer controller EPS RO.90 (PA-EPS_RO.90_63885)

Format: PDF, 2 pages

Language: English

15. Operate and Maintenance manual (OMM-WWHSU-00311)

Format: PDF, 42 pages

Language: English

Table of Contents:

Truck

Safety instructions

Operating environment

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

16. Wiring Diagram (EL-TS1141211_G)

Format: PDF, 10 pages

Language: English

Table of Contents:

3-6968: NSS15N,NSS20N

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 2

5: STEERING CIRCUIT

6: DISPLAY AND CONTROL CIRCUITS

7: HYDRAULICS, AUX. DEVICES

8: AUX. DEVICES

9: COLD STORAGE

10: INSTR. PANEL GROUNDING

17. Wiring Diagram (EL-TS1150908_RevE)

Language: English

18. Hydraulic Circuit Diagram (HY-TH79_0707)

Format: PDF, 1 page

Language: English

Included

Fault Codes List

1Service Manual

13Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары