$49.99

Fault Codes List

2Service Manual

1Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

1Illustrated factory set of Service Manuals for Mitsubishi Reach Trucks Models RBM20N2 and RBM25N2.

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RBM20N2

RBM25N2

The manual comprises 7 documents, including two Fault Codes Lists, the Service Manual, Operate and Maintenance manual, two Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List: Warnings (ER-Warning_list)

Format: PDF, 2 pages

Language: English

2. Fault Codes List: Errors (ER-Error_list)

Format: PDF, 6 pages

Language: English

3. Service Manual (SM-633560-ENA_18)

Format: PDF, 764 pages

Language: English

Table of Contents:

Foreword

How to read thismanual

Safety-related signs

Symbols and abbreviations

Units

Safety instructions

Safety requirements for industrial trucks

Repairs and structural modifications

Service area safety

Personal safety

Work safety

Operating temperature

General information

Truck models covered by this manual

Identification plates on the truck

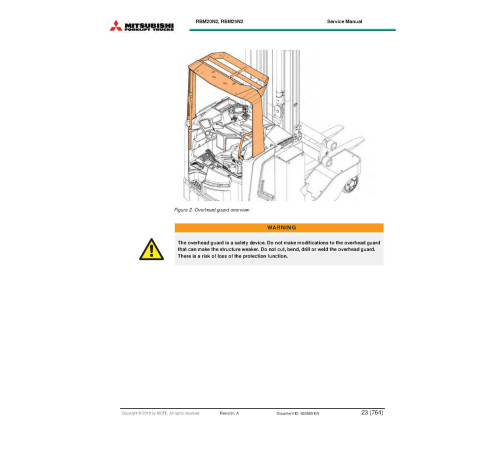

Overview of the truck

Mechanical maintenance

Lifting points

How to tow the truck

Transportation

Assembly and commissioning

Order spare parts

How to clean the truck

Truck covers

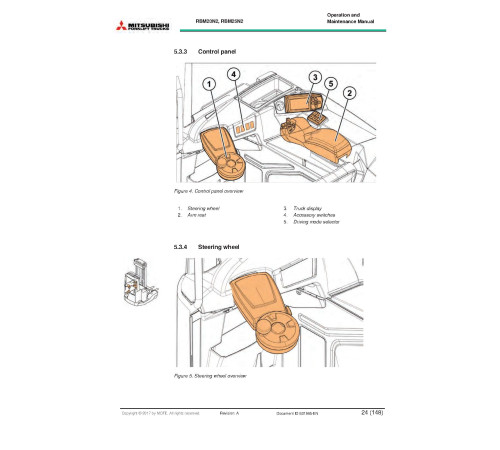

Steering wheel

Transmission gear

Slewing bearing

Traction wheel

Corner supports

Load wheels

Battery roller frame

Remove the battery roller frame

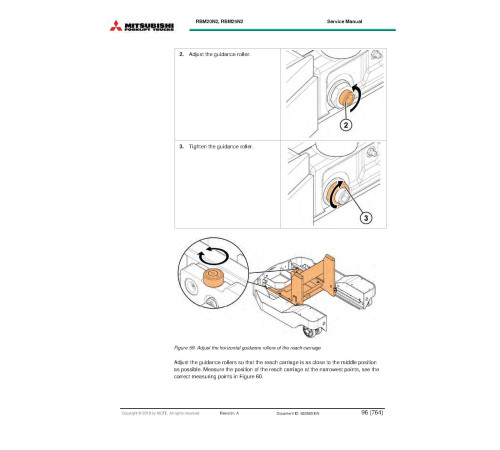

Reach carriage

Mast

Operator’s seat

Arm rest

Electrical operation

How to use the schematic diagram

Power supply

Safety circuit (emergency stop button)

Key switch

Traction

Battery maintenance

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

Requirements for battery charging areas

Charge the battery

Measure the specific gravity of the battery

Acquire a new battery

Replace the battery

Electric system maintenance

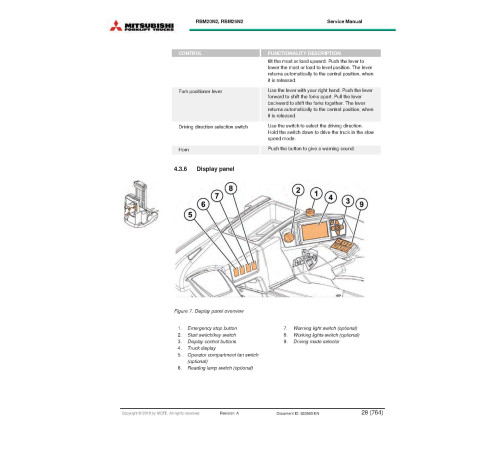

Display panel

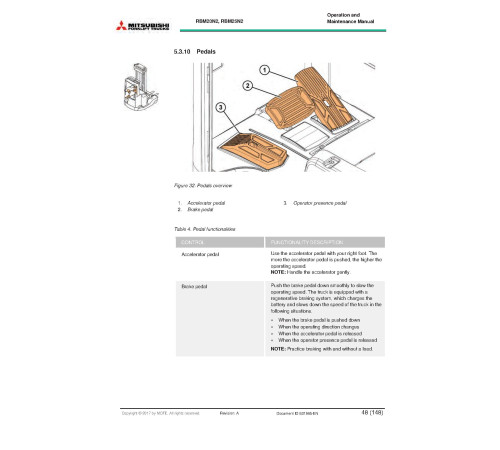

Pedals

Instrument panel

Motor compartment

Sensors

Lowering cut-off sensor

Electric system adjustments and measurements

Calibrate the arm rest levers

Insulation resistance test

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Hydraulic system

Hydraulic valve unit

TruckTool Diagnostics

Location of the service socket

Parameter descriptions

VCM master

Traction controller

Pump controller

EPS controller

Alarm codes

VCM

Traction controller

Display

Pump controller

EPS

Arm rest controller

Service data

Special tightening torques

Tightening torque for standard bolts and nuts

Maintenance check list

Lubrication

Hazardous waste and disposal

Special tools

Storage

Decommissioning

Options

Special color labels

Customer design labels

Truck display languages

Accessory rack

Accessory rack under the truck floor

Reading lamp

Audio system

Warning light

Warning light with an extension arm

Working lights

Blue spot rear light

Operator compartment fan

Drive alarm (programmable)

Steel safety net for overhead guard

Plexiglass safety cover for the overhead guard

Left shoulder protection plate

Fire extinguisher

Install the fire extinguisher

DC-DC converter

Install the DC-DC converter

Battery changing device for 2 batteries

Battery connector + cables

Charger connector

Load weight indicator

Operator’s seat options and accessories

PIN code access to the Start switch

Abbot 2

Technical specification

RBM20N2, RBM25N2

Mast heights

Index

APPENDIX A: Stickers .

4. Operate and Maintenance manual (OMM-631965-EN_17)

Format: PDF, 148 pages

Language: English

5. Wiring Diagram (EL-3-7775_RevA)

Format: PDF, 14 pages

Language: English

6. Wiring Diagram (EL-3-7775_JT_RevC)

Format: PDF, 6 pages

Language: English

7. Hydraulic Circuit Diagram (HY-Main_Hydraulic_Circuit)

Format: PDF, 1 page

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RBM20N2

RBM25N2

The manual comprises 7 documents, including two Fault Codes Lists, the Service Manual, Operate and Maintenance manual, two Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List: Warnings (ER-Warning_list)

Format: PDF, 2 pages

Language: English

2. Fault Codes List: Errors (ER-Error_list)

Format: PDF, 6 pages

Language: English

3. Service Manual (SM-633560-ENA_18)

Format: PDF, 764 pages

Language: English

Table of Contents:

Foreword

How to read thismanual

Safety-related signs

Symbols and abbreviations

Units

Safety instructions

Safety requirements for industrial trucks

Repairs and structural modifications

Service area safety

Personal safety

Work safety

Operating temperature

General information

Truck models covered by this manual

Identification plates on the truck

Overview of the truck

Mechanical maintenance

Lifting points

How to tow the truck

Transportation

Assembly and commissioning

Order spare parts

How to clean the truck

Truck covers

Steering wheel

Transmission gear

Slewing bearing

Traction wheel

Corner supports

Load wheels

Battery roller frame

Remove the battery roller frame

Reach carriage

Mast

Operator’s seat

Arm rest

Electrical operation

How to use the schematic diagram

Power supply

Safety circuit (emergency stop button)

Key switch

Traction

Battery maintenance

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

Requirements for battery charging areas

Charge the battery

Measure the specific gravity of the battery

Acquire a new battery

Replace the battery

Electric system maintenance

Display panel

Pedals

Instrument panel

Motor compartment

Sensors

Lowering cut-off sensor

Electric system adjustments and measurements

Calibrate the arm rest levers

Insulation resistance test

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Hydraulic system

Hydraulic valve unit

TruckTool Diagnostics

Location of the service socket

Parameter descriptions

VCM master

Traction controller

Pump controller

EPS controller

Alarm codes

VCM

Traction controller

Display

Pump controller

EPS

Arm rest controller

Service data

Special tightening torques

Tightening torque for standard bolts and nuts

Maintenance check list

Lubrication

Hazardous waste and disposal

Special tools

Storage

Decommissioning

Options

Special color labels

Customer design labels

Truck display languages

Accessory rack

Accessory rack under the truck floor

Reading lamp

Audio system

Warning light

Warning light with an extension arm

Working lights

Blue spot rear light

Operator compartment fan

Drive alarm (programmable)

Steel safety net for overhead guard

Plexiglass safety cover for the overhead guard

Left shoulder protection plate

Fire extinguisher

Install the fire extinguisher

DC-DC converter

Install the DC-DC converter

Battery changing device for 2 batteries

Battery connector + cables

Charger connector

Load weight indicator

Operator’s seat options and accessories

PIN code access to the Start switch

Abbot 2

Technical specification

RBM20N2, RBM25N2

Mast heights

Index

APPENDIX A: Stickers .

4. Operate and Maintenance manual (OMM-631965-EN_17)

Format: PDF, 148 pages

Language: English

5. Wiring Diagram (EL-3-7775_RevA)

Format: PDF, 14 pages

Language: English

6. Wiring Diagram (EL-3-7775_JT_RevC)

Format: PDF, 6 pages

Language: English

7. Hydraulic Circuit Diagram (HY-Main_Hydraulic_Circuit)

Format: PDF, 1 page

Language: English

Included

Fault Codes List

2Service Manual

1Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары