$49.99

Fault Codes List

3Service Manual

5Technical Manual

2Operate and Maintenance manual

1Wiring Diagram

2Illustrated factory set of Service Manuals for Mitsubishi Reach Trucks Models RBM20K and RBM25K.

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RBM20K

RBM25K

The manual comprises 15 documents, including three Fault Codes Lists, five Service Manuals, two Technical Manuals, the Operate and Maintenance manual, two Wiring Diagrams, and two Hydraulic Circuit Diagrams

1. Fault Codes List (Traction_and_pump_controller)

Format: PDF, 1 page

Language: English

2. Fault Codes List (Steering_inverter_errors)

Format: PDF, 1 page

Language: English

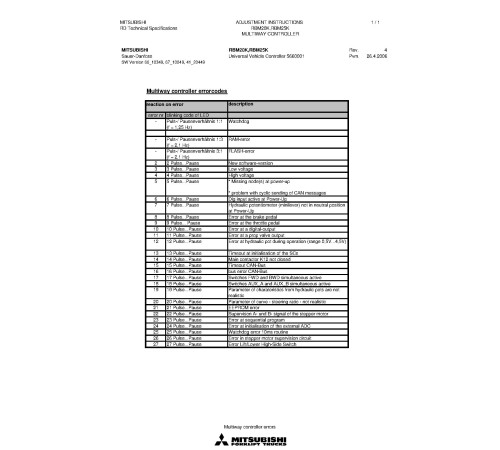

3. Fault Codes List (Multiway_controller_errors)

Format: PDF, 1 page

Language: English

4. Service Manual (SM-631057A_16)

Format: PDF, 95 pages

Language: English

Table of Contents:

FOREWORD

HOW TO READ THIS MANUAL

Safety-related signs

Symbols and abbreviations

Units

SAFETY INSTRUCTIONS

Service area safety

Personal safety

Work safety

GENERAL INFORMATION

Truck model covered by this manual

Identification plates on the truck

FORKS

Fork inspection

Mast chains

ELECTRICAL OPERATION

How to use the schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

BATTERY MAINTENANCE

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

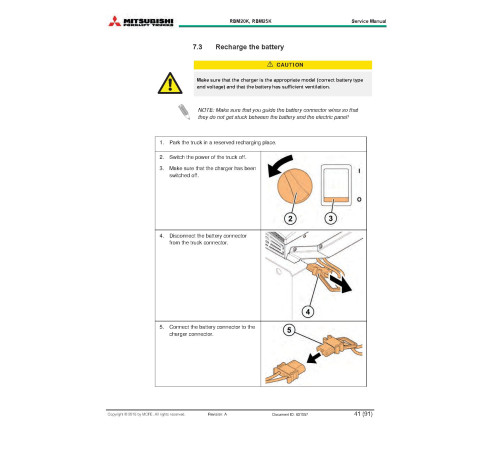

Recharge the battery

Measure the specific gravity of the battery

Replace the battery

ELECTRIC SYSTEM MAINTENANCE

Electric system

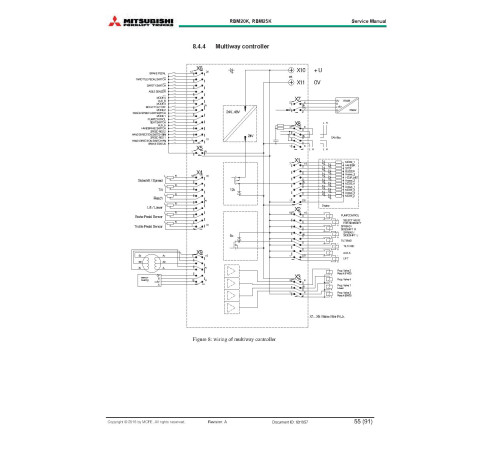

Controllers

Controller installation

Connections

Power stages

Control stages

PARAMETER LISTS

General instruction

Setup using the hand-held terminal

FAULT AND STATE REPORTS

List of muitiway controller

Traction and pump controller

Steering controllers

TECHNICAL DATA

RBM20K, RBM25K

Mast heights

ANNEX

5. Service Manual: dACi-TA B2/C3 Traction system for induction motor (dACi2-EN)

Format: PDF, 27 pages

Language: English

6. Service Manual: CANION (CANION_0300)

Format: PDF, 38 pages

Language: English

Table of Contents:

Introduction

About CANION Documentation

Technical Description

Principles of Operation

Applications

Order Picker

Order Picker

Interfacing to CANION

Interfacing Input Devices

Interfacing Input Devices

Interfacing Output Devices

Can Bus Communications

Installation and Wiring

CANION Installation

CANION Installation

Specifications

Electrical Power Inputs & Outputs

7. Service Manual: Advanced Power Steering (APS-Advanced_Power_Steering)

Format: PDF, 55 pages

Language: English

Table of Contents:

Table of Contents

Introduction

About APS Documentation

About the Advanced Power Steering Unit

APS Installation

Installing APS in Vehicle

Installing Steering Feedback Sensors

Installing Steering Input Sensors

Wiring the APS

Startup and Commissioning

Initial Startup

Maintenance

Maintenance Procedures

APS Replacement Procedures

Troubleshooting

Introduction

The Troubleshooting Guide

8. Service Manual: AC Superdrive (AC-SuperDrive)

Format: PDF, 53 pages

Language: English

Table of Contents:

Scope of this Manual

Related Documents

Intended Use of the AC SuperDrive

Product Identification

Technical Support

Product Warranty

Introduction

Tools and Equipment Required

Orientation

Clearances for Access and Air Circulation

Procedure

Introduction

Tools and Equipment Required

Motor and Battery Connections

General

Making Connections to Terminal Posts

Fuses

Inrush Current Limiting Resistance

Main Contactor

Key Start Input

Control and I/O Connections

General

ID0 and ID1 Inputs

Encoder Signals

Temperature Sensor

CAN Bus Signals

Crimping Contacts onto Signal Conductors

Installing Crimped Contacts in Connector Housing

General

Checks Prior to Initial Powerup

Verifying AC SuperDrive Readiness for Operation

Configuring the AC SuperDrive for the Application

Final Operational Checks in Vehicle

Introduction

Periodic Preventive Maintenance

AC SuperDrive Replacement Procedure

Drive Removal

Drive Installation

Scope of the Troubleshooting Guide

Using the Troubleshooting Guide

Organization of Troubleshooting Guide

About Errors and Warnings

Error Logging

Using the Troubleshooting Charts

Information for OEMs Preparing User Documentation

Symptom: Main Contactor doesn’t close after switching on Key Switch

Symptom: Fuse to Power Stage is blown

Symptom: AC SuperDrive Status Indicator is blinking or off

Symptom: Motor runs only at low speed and with a ticking sound

Error Code 1: Pulse Sensor Error

Error Code 2: Motor Temperature High

Warning Code 16: Power limited due to Motor Overtemp.

Error Code 4: Heatsink Temperature high

Warning Code 1: Power Limited due to Heatsink Overtemp.

Error Code 8: Overcurrent

Error Code 16: DC Bus High - hardware detected

Error Code 32: DC Bus High - software detected

Error Code 64: DC Bus Low

Error Code 128: No Charging DC Bus

Error Code 256: CAN - too many Errors

Error Code 512: CAN Watchdog Time-out

Error Code 1024: Missing “Okay to Start” from Truck Controller

Error Code 2048: Contradictory Commands from Truck Controller

Error Code 4096: Potentiometer Values Out of Range

Warning Code 2: Heatsink Temperature Sensor - Open Circuit

Warning Code 4: Heatsink Temperature Sensor - Short Circuit

Warning Code 8: Power limited - temp < -20 deg. C

Warning Code 32: Motor Temperature Sensor - Open Circuit

Warning Code 64: Motor Temperature Sensor - Short Circuit

Warning Code 128: Speed from Truck Controller Out of Range

Warning Code 256: Current Calibration Error

Warning Code 512: Reverted to Default Parameters

89R09003A_UM.pdf

Scope of this Manual

Related Documents

Intended Use of the AC SuperDrive

Product Identification

Technical Support

Product Warranty

Introduction

Tools and Equipment Required

Orientation

Clearances for Access and Air Circulation

Procedure

Introduction

Tools and Equipment Required

Motor and Battery Connections

Control and I/O Connections

General

Checks Prior to Initial Powerup

Verifying AC SuperDrive Readiness for Operation

Configuring the AC SuperDrive for the Application

Final Operational Checks in Vehicle

Introduction

Periodic Preventive Maintenance

AC SuperDrive Replacement Procedure

Obtaining Factory Repair

Scope of the Troubleshooting Guide

Using the Troubleshooting Guide

Information for OEMs Preparing User Documentation

Symptom: Main Contactor doesn’t close after switching on Key Switch

Symptom: Fuse to Power Stage is blown

Symptom: AC SuperDrive Status Indicator is blinking or off

Symptom: Motor runs only at low speed and with a ticking sound

Error Code 1: Pulse Sensor Error

Error Code 2: Motor Temperature High

Warning Code 16: Power limited due to Motor Overtemp.

Error Code 4: Heatsink Temperature high

Warning Code 1: Power Limited due to Heatsink Overtemp.

Error Code 8: Overcurrent

Error Code 16: DC Bus High - hardware detected

Error Code 32: DC Bus High - software detected

Error Code 64: DC Bus Low

Error Code 128: No Charging DC Bus

Error Code 256: CAN - too many Errors

Error Code 512: CAN Watchdog Time-out

Error Code 1024: Missing “Okay to Start” from Truck Controller

Error Code 2048: Contradictory Commands from Truck Controller

Error Code 4096: Potentiometer Values Out of Range

Warning Code 2: Heatsink Temperature Sensor - Open Circuit

Warning Code 4: Heatsink Temperature Sensor - Short Circuit

Warning Code 8: Power limited - temp < -20 deg. C

Warning Code 32: Motor Temperature Sensor - Open Circuit

Warning Code 64: Motor Temperature Sensor - Short Circuit

Warning Code 128: Speed from Truck Controller Out of Range

Warning Code 256: Current Calibration Error

Warning Code 512: Reverted to Default Parameters

um.pdf

9. Technical Manual: PARAMETER SETTINGS (PA-RBM20K_RBM25K)

Format: PDF, 7 pages

Language: English

10. Technical Manual: PARAMETER SETTINGS (PA-Adjustment_instructions_260406)

Format: PDF, 2 pages

Language: English

11. Operate and Maintenance manual (OMM-WHOMM0002)

Format: PDF, 27 pages

Language: English

Table of Contents:

FOREWORD

INSTRUCTIONS ON OPERA TING THE TRUCK

OCCUP A TIONALSAFETY

LOAD HANDLING

DRIVING

P ARKING

OTHER WORKINGINSTRUCTIONS

RECHARGING AND REPLACING THE BA TTERY

HAZARDOUS W ASTE AND DISPOSAL

ORDERINGSP ARE P ARTS

USE OF THE TRUCK

THE OPERA TOR’S NORMALDRIVINGPOSITION

NOISE

CONTROLS AND THEIR DISPLA YS

ADJUSTING THE DRIVINGPOSITION

OPERATION

HANDLING THE LOAD

EMERGENCY PROCEDURE

INSPECTIONS, MAINTENANCE AND REP AIR

FL YBY WIRE” ELECTRONIC STEERING

ADDITIONALINSTRUCTIONS FOR THE COLD STORAGE TRUCKS

TROUBLESHOOTING .

12. Wiring Diagram (EL-TS1050508)

Format: PDF, 19 pages

Language: English

Table of Contents:

POWER SUPPLY 48V

MAIN CIRCUITS

DRIVE CIRCUIT

DRIVE CIRCUIT 2

STEERING CIRCUIT 1

HYDRAULIC CONTROL CIRCUIT

AUX DEVICES

STEERING CIRCUIT

CONTROL CIRCUIT

SIGNAL/LIGHT CIRCUITS

CSM: FLASH LIGHTS WITH RUBBER BODY

24V POWER SUPPLY / AUX DEVICES

MAIN WIRE HARNESS 479690

MAIN WIRE HARNESS 479690

PUSH WIRE HARNESS 480917

SUPPLY AND MOTOR CABLES 479691

INSTRUMENT PANEL WIRE HARNESS 479692

PIN CODE LUCK 480016

PEDALS 482458

13. Wiring Diagram (EL-TS761104)

Format: PDF, 18 pages

Language: English

Table of Contents:

POWERSUPPLY 48V

POWERSUPPLY 12/24V

MAINCIRCUITS

DRIVECIRCUIT 1

DRIVECIRCUIT 2

STEERING CIRCUIT

STEERING CIRCUIT 2

STEERING CIRCUIT 3

HYDRAULIC CONTROL CIRCUIT 1

HYDRAULIC CONTROL CIRCUIT 2

CONTROL CIRCUIT 1

CONTROL CIRCUIT 2

SIGNAL- /LIGHTCIRCUIT

FANS, AUX.DEVICES

AUX.DEVICES

LAYOUT

WIRE HARNESS W3: RL468152

14. Hydraulic Circuit Diagram (HY-TH51_1005)

Format: PDF, 1 page

Language: English

15. Hydraulic Circuit Diagram (HY-TH51_0804)

Format: PDF, 1 page

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RBM20K

RBM25K

The manual comprises 15 documents, including three Fault Codes Lists, five Service Manuals, two Technical Manuals, the Operate and Maintenance manual, two Wiring Diagrams, and two Hydraulic Circuit Diagrams

1. Fault Codes List (Traction_and_pump_controller)

Format: PDF, 1 page

Language: English

2. Fault Codes List (Steering_inverter_errors)

Format: PDF, 1 page

Language: English

3. Fault Codes List (Multiway_controller_errors)

Format: PDF, 1 page

Language: English

4. Service Manual (SM-631057A_16)

Format: PDF, 95 pages

Language: English

Table of Contents:

FOREWORD

HOW TO READ THIS MANUAL

Safety-related signs

Symbols and abbreviations

Units

SAFETY INSTRUCTIONS

Service area safety

Personal safety

Work safety

GENERAL INFORMATION

Truck model covered by this manual

Identification plates on the truck

FORKS

Fork inspection

Mast chains

ELECTRICAL OPERATION

How to use the schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

BATTERY MAINTENANCE

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

Recharge the battery

Measure the specific gravity of the battery

Replace the battery

ELECTRIC SYSTEM MAINTENANCE

Electric system

Controllers

Controller installation

Connections

Power stages

Control stages

PARAMETER LISTS

General instruction

Setup using the hand-held terminal

FAULT AND STATE REPORTS

List of muitiway controller

Traction and pump controller

Steering controllers

TECHNICAL DATA

RBM20K, RBM25K

Mast heights

ANNEX

5. Service Manual: dACi-TA B2/C3 Traction system for induction motor (dACi2-EN)

Format: PDF, 27 pages

Language: English

6. Service Manual: CANION (CANION_0300)

Format: PDF, 38 pages

Language: English

Table of Contents:

Introduction

About CANION Documentation

Technical Description

Principles of Operation

Applications

Order Picker

Order Picker

Interfacing to CANION

Interfacing Input Devices

Interfacing Input Devices

Interfacing Output Devices

Can Bus Communications

Installation and Wiring

CANION Installation

CANION Installation

Specifications

Electrical Power Inputs & Outputs

7. Service Manual: Advanced Power Steering (APS-Advanced_Power_Steering)

Format: PDF, 55 pages

Language: English

Table of Contents:

Table of Contents

Introduction

About APS Documentation

About the Advanced Power Steering Unit

APS Installation

Installing APS in Vehicle

Installing Steering Feedback Sensors

Installing Steering Input Sensors

Wiring the APS

Startup and Commissioning

Initial Startup

Maintenance

Maintenance Procedures

APS Replacement Procedures

Troubleshooting

Introduction

The Troubleshooting Guide

8. Service Manual: AC Superdrive (AC-SuperDrive)

Format: PDF, 53 pages

Language: English

Table of Contents:

Scope of this Manual

Related Documents

Intended Use of the AC SuperDrive

Product Identification

Technical Support

Product Warranty

Introduction

Tools and Equipment Required

Orientation

Clearances for Access and Air Circulation

Procedure

Introduction

Tools and Equipment Required

Motor and Battery Connections

General

Making Connections to Terminal Posts

Fuses

Inrush Current Limiting Resistance

Main Contactor

Key Start Input

Control and I/O Connections

General

ID0 and ID1 Inputs

Encoder Signals

Temperature Sensor

CAN Bus Signals

Crimping Contacts onto Signal Conductors

Installing Crimped Contacts in Connector Housing

General

Checks Prior to Initial Powerup

Verifying AC SuperDrive Readiness for Operation

Configuring the AC SuperDrive for the Application

Final Operational Checks in Vehicle

Introduction

Periodic Preventive Maintenance

AC SuperDrive Replacement Procedure

Drive Removal

Drive Installation

Scope of the Troubleshooting Guide

Using the Troubleshooting Guide

Organization of Troubleshooting Guide

About Errors and Warnings

Error Logging

Using the Troubleshooting Charts

Information for OEMs Preparing User Documentation

Symptom: Main Contactor doesn’t close after switching on Key Switch

Symptom: Fuse to Power Stage is blown

Symptom: AC SuperDrive Status Indicator is blinking or off

Symptom: Motor runs only at low speed and with a ticking sound

Error Code 1: Pulse Sensor Error

Error Code 2: Motor Temperature High

Warning Code 16: Power limited due to Motor Overtemp.

Error Code 4: Heatsink Temperature high

Warning Code 1: Power Limited due to Heatsink Overtemp.

Error Code 8: Overcurrent

Error Code 16: DC Bus High - hardware detected

Error Code 32: DC Bus High - software detected

Error Code 64: DC Bus Low

Error Code 128: No Charging DC Bus

Error Code 256: CAN - too many Errors

Error Code 512: CAN Watchdog Time-out

Error Code 1024: Missing “Okay to Start” from Truck Controller

Error Code 2048: Contradictory Commands from Truck Controller

Error Code 4096: Potentiometer Values Out of Range

Warning Code 2: Heatsink Temperature Sensor - Open Circuit

Warning Code 4: Heatsink Temperature Sensor - Short Circuit

Warning Code 8: Power limited - temp < -20 deg. C

Warning Code 32: Motor Temperature Sensor - Open Circuit

Warning Code 64: Motor Temperature Sensor - Short Circuit

Warning Code 128: Speed from Truck Controller Out of Range

Warning Code 256: Current Calibration Error

Warning Code 512: Reverted to Default Parameters

89R09003A_UM.pdf

Scope of this Manual

Related Documents

Intended Use of the AC SuperDrive

Product Identification

Technical Support

Product Warranty

Introduction

Tools and Equipment Required

Orientation

Clearances for Access and Air Circulation

Procedure

Introduction

Tools and Equipment Required

Motor and Battery Connections

Control and I/O Connections

General

Checks Prior to Initial Powerup

Verifying AC SuperDrive Readiness for Operation

Configuring the AC SuperDrive for the Application

Final Operational Checks in Vehicle

Introduction

Periodic Preventive Maintenance

AC SuperDrive Replacement Procedure

Obtaining Factory Repair

Scope of the Troubleshooting Guide

Using the Troubleshooting Guide

Information for OEMs Preparing User Documentation

Symptom: Main Contactor doesn’t close after switching on Key Switch

Symptom: Fuse to Power Stage is blown

Symptom: AC SuperDrive Status Indicator is blinking or off

Symptom: Motor runs only at low speed and with a ticking sound

Error Code 1: Pulse Sensor Error

Error Code 2: Motor Temperature High

Warning Code 16: Power limited due to Motor Overtemp.

Error Code 4: Heatsink Temperature high

Warning Code 1: Power Limited due to Heatsink Overtemp.

Error Code 8: Overcurrent

Error Code 16: DC Bus High - hardware detected

Error Code 32: DC Bus High - software detected

Error Code 64: DC Bus Low

Error Code 128: No Charging DC Bus

Error Code 256: CAN - too many Errors

Error Code 512: CAN Watchdog Time-out

Error Code 1024: Missing “Okay to Start” from Truck Controller

Error Code 2048: Contradictory Commands from Truck Controller

Error Code 4096: Potentiometer Values Out of Range

Warning Code 2: Heatsink Temperature Sensor - Open Circuit

Warning Code 4: Heatsink Temperature Sensor - Short Circuit

Warning Code 8: Power limited - temp < -20 deg. C

Warning Code 32: Motor Temperature Sensor - Open Circuit

Warning Code 64: Motor Temperature Sensor - Short Circuit

Warning Code 128: Speed from Truck Controller Out of Range

Warning Code 256: Current Calibration Error

Warning Code 512: Reverted to Default Parameters

um.pdf

9. Technical Manual: PARAMETER SETTINGS (PA-RBM20K_RBM25K)

Format: PDF, 7 pages

Language: English

10. Technical Manual: PARAMETER SETTINGS (PA-Adjustment_instructions_260406)

Format: PDF, 2 pages

Language: English

11. Operate and Maintenance manual (OMM-WHOMM0002)

Format: PDF, 27 pages

Language: English

Table of Contents:

FOREWORD

INSTRUCTIONS ON OPERA TING THE TRUCK

OCCUP A TIONALSAFETY

LOAD HANDLING

DRIVING

P ARKING

OTHER WORKINGINSTRUCTIONS

RECHARGING AND REPLACING THE BA TTERY

HAZARDOUS W ASTE AND DISPOSAL

ORDERINGSP ARE P ARTS

USE OF THE TRUCK

THE OPERA TOR’S NORMALDRIVINGPOSITION

NOISE

CONTROLS AND THEIR DISPLA YS

ADJUSTING THE DRIVINGPOSITION

OPERATION

HANDLING THE LOAD

EMERGENCY PROCEDURE

INSPECTIONS, MAINTENANCE AND REP AIR

FL YBY WIRE” ELECTRONIC STEERING

ADDITIONALINSTRUCTIONS FOR THE COLD STORAGE TRUCKS

TROUBLESHOOTING .

12. Wiring Diagram (EL-TS1050508)

Format: PDF, 19 pages

Language: English

Table of Contents:

POWER SUPPLY 48V

MAIN CIRCUITS

DRIVE CIRCUIT

DRIVE CIRCUIT 2

STEERING CIRCUIT 1

HYDRAULIC CONTROL CIRCUIT

AUX DEVICES

STEERING CIRCUIT

CONTROL CIRCUIT

SIGNAL/LIGHT CIRCUITS

CSM: FLASH LIGHTS WITH RUBBER BODY

24V POWER SUPPLY / AUX DEVICES

MAIN WIRE HARNESS 479690

MAIN WIRE HARNESS 479690

PUSH WIRE HARNESS 480917

SUPPLY AND MOTOR CABLES 479691

INSTRUMENT PANEL WIRE HARNESS 479692

PIN CODE LUCK 480016

PEDALS 482458

13. Wiring Diagram (EL-TS761104)

Format: PDF, 18 pages

Language: English

Table of Contents:

POWERSUPPLY 48V

POWERSUPPLY 12/24V

MAINCIRCUITS

DRIVECIRCUIT 1

DRIVECIRCUIT 2

STEERING CIRCUIT

STEERING CIRCUIT 2

STEERING CIRCUIT 3

HYDRAULIC CONTROL CIRCUIT 1

HYDRAULIC CONTROL CIRCUIT 2

CONTROL CIRCUIT 1

CONTROL CIRCUIT 2

SIGNAL- /LIGHTCIRCUIT

FANS, AUX.DEVICES

AUX.DEVICES

LAYOUT

WIRE HARNESS W3: RL468152

14. Hydraulic Circuit Diagram (HY-TH51_1005)

Format: PDF, 1 page

Language: English

15. Hydraulic Circuit Diagram (HY-TH51_0804)

Format: PDF, 1 page

Language: English

Included

Fault Codes List

3Service Manual

5Technical Manual

2Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары