Illustrated factory set of Service Manuals for Mitsubishi Order Pickers Models OPBL10N, OPBL10NF and OPBL10NV.

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your order picker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

OPBL10N

OPBL10NF

OPBL10NV

The manual comprises 4 documents, including three Service Manuals, and the Operate and Maintenance manual

1. Service Manual (SM-WHSM0016)

Format: PDF, 35 pages

Language: English

2. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

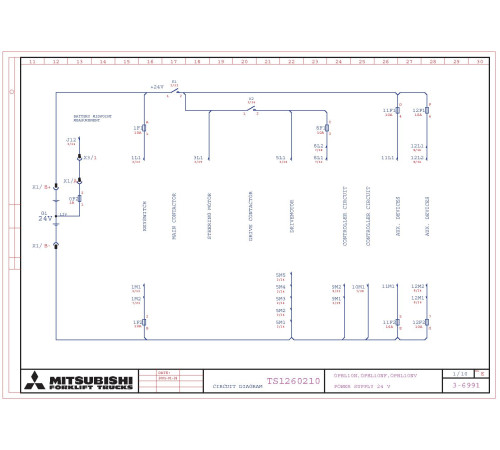

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

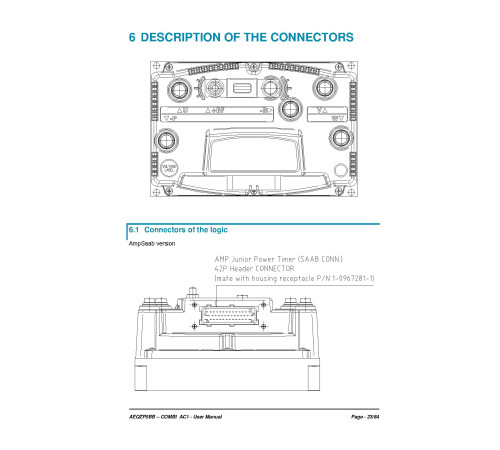

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

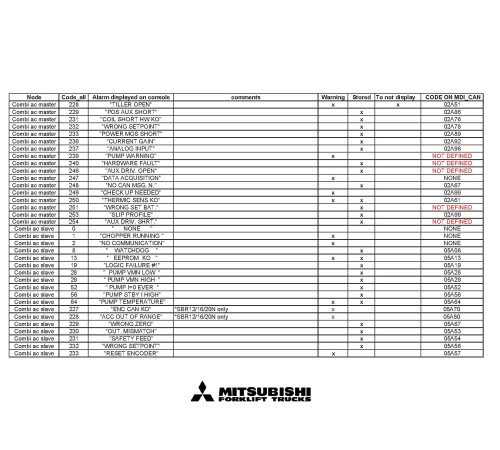

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

3. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

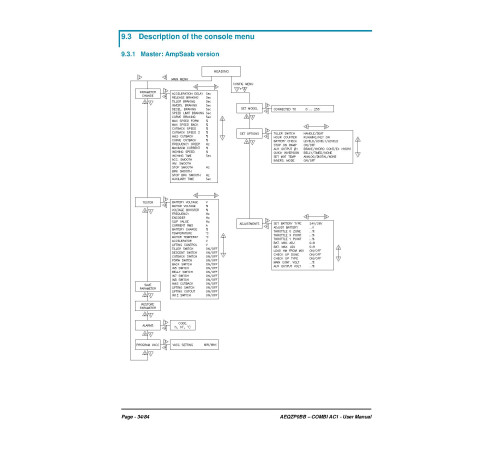

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

4. Operate and Maintenance manual (OMM-WWHOU-00011)

Format: PDF, 43 pages

Language: English

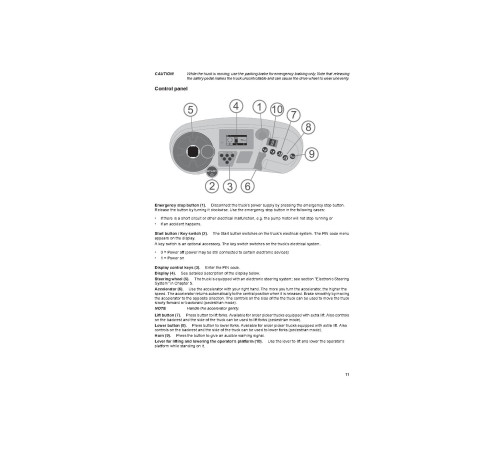

Table of Contents:

Truck

Safety instructions

Operating environment

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your order picker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

OPBL10N

OPBL10NF

OPBL10NV

The manual comprises 4 documents, including three Service Manuals, and the Operate and Maintenance manual

1. Service Manual (SM-WHSM0016)

Format: PDF, 35 pages

Language: English

2. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

3. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

4. Operate and Maintenance manual (OMM-WWHOU-00011)

Format: PDF, 43 pages

Language: English

Table of Contents:

Truck

Safety instructions

Operating environment

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

Included

Service Manual

3Operate and Maintenance manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары