$49.99

Fault Codes List

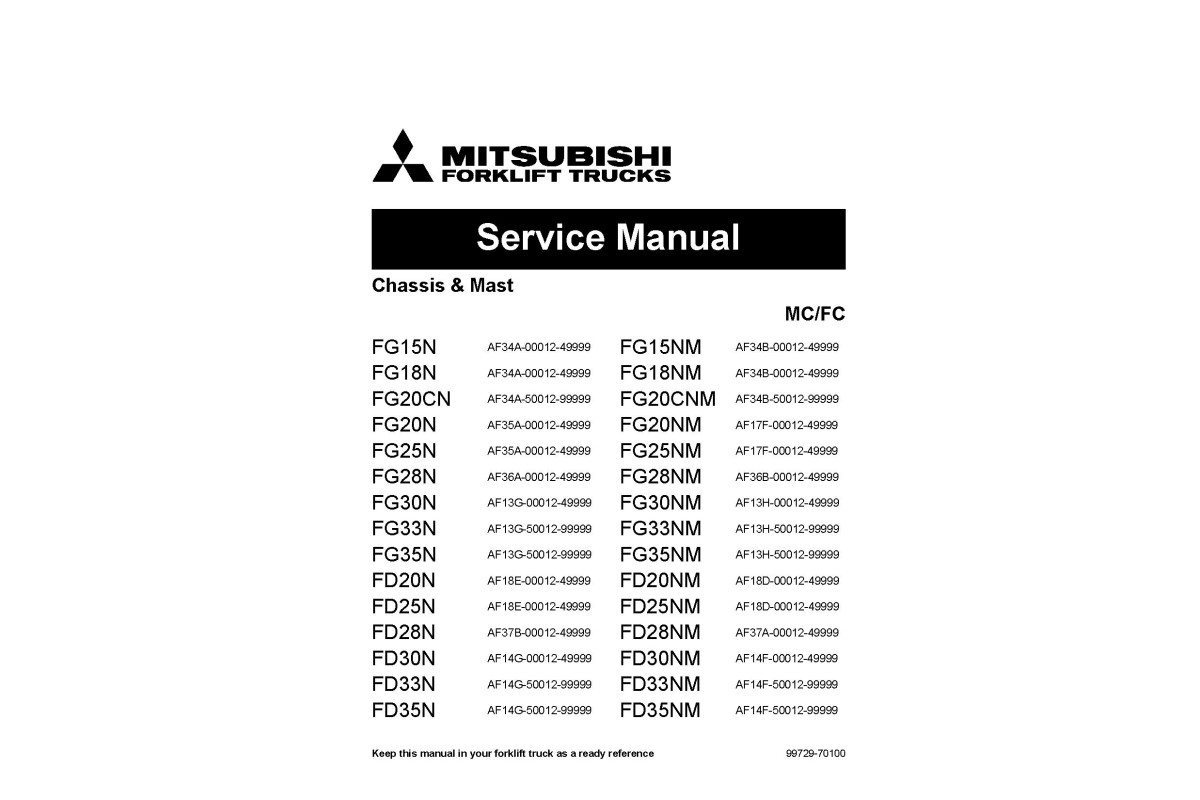

1Service Manual

2Engine Technical Manual

1Wiring Diagram

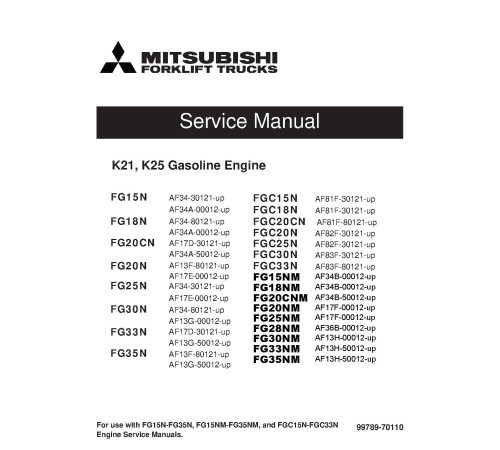

3Illustrated factory set of Service Manuals for Mitsubishi Gasoline Forklift Trucks Models FG15NM (AF34B-00012-49999), FG18NM (AF34B-00012-49999), FG20CNM (AF34B-50012-99999), FG20NM (AF17F-00012-49999), FG25NM (AF17F-00012-49999), FG28NM (AF36B-00012-49999), FG30NM (AF13H-00012-49999), FG33NM (AF13H-50012-99999) and FG35NM (AF13H-50012-99999).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing engine, and troubleshooting for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FG15NM (AF34B-00012-49999)

FG18NM (AF34B-00012-49999)

FG20CNM (AF34B-50012-99999)

FG20NM (AF17F-00012-49999)

FG25NM (AF17F-00012-49999)

FG28NM (AF36B-00012-49999)

FG30NM (AF13H-00012-49999)

FG33NM (AF13H-50012-99999)

FG35NM (AF13H-50012-99999)

The manual comprises 6 documents, including the Fault Codes List, Service Manual, Engine Technical Manual, and three Wiring Diagrams

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual (SM-99729-70100_A17)

Format: PDF, 710 pages

Language: English

Table of Contents:

GENERAL INFORMATION

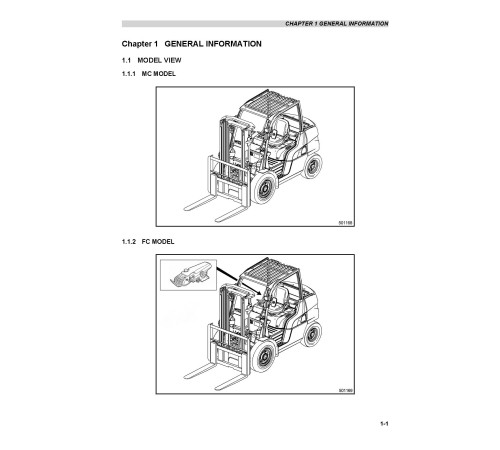

Model View

Truck Models Covered

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Removal and Installation

Inspection and Adjustment

ELECTRICAL SYSTEM

Chassis Electrical Components and Wiring Outline

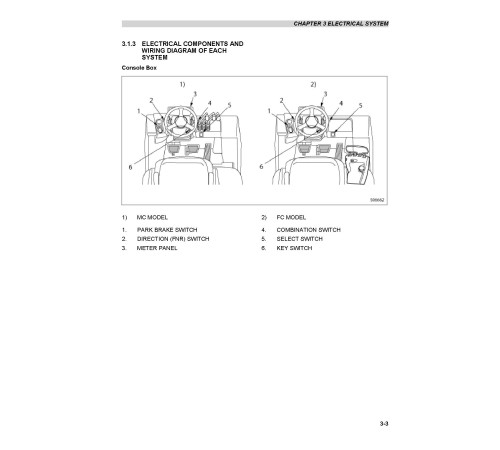

Console Box

Main Electrical Components

Battery Maintenance

Meter Panel

Wire Color

Troubleshooting

CONTROLLERS

Outline

Main Functions

Service Tool Functions

Mast Interlock System

Driving Interlock System

Seat Belt Warning Icon

Parking Brake Warning Alarm and Icon

Harness Codes

Truck Status Display and Troubleshooting

POWER TRAIN

Removal and Installation (MC Models)

Removal and Installation (FC Models)

POWERSHIFT TRANSMISSION

Structure and Functions

Removal and Installation

Outline

Powershift Transmission, Disassembly

Powershift Transmission, Assembly

Control Valve, Disassembly

Control Valve, Assembly

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removal and Installation

Disassembly and Assembly

Troubleshooting

Service Data

REAR AXLE

Structure and Functions

Removal and Installation

Disassembly and Assembly

BRAKE SYSTEM

Structure

Disassembly and Assembly

Inspection and Adjustment

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembly and Assembly

Steering Valve

Troubleshooting

Service Data

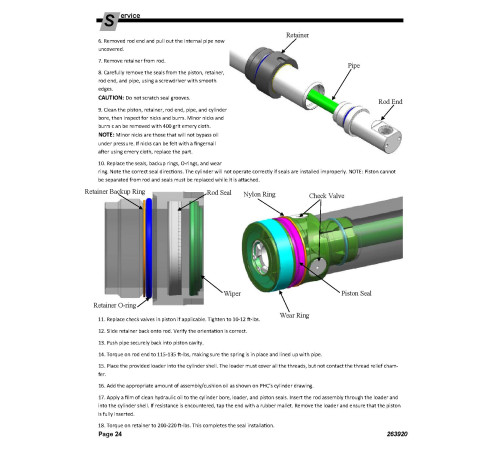

HYDRAULIC SYSTEM

Structure and Functions

Disassembly and Reassembly

Inspection and Adjustment

Troubleshooting

Service Data

MC Control Valve

FC Control Valve

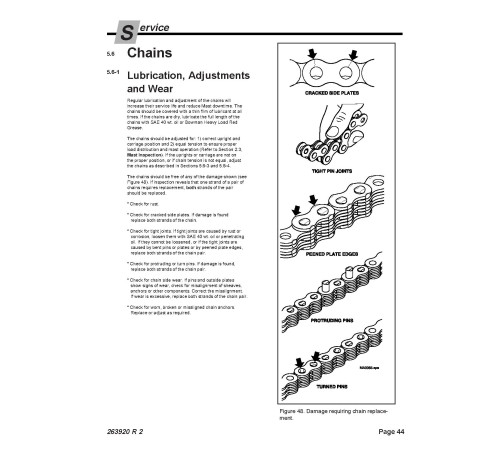

MAST AND FORKS

Simplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Duplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

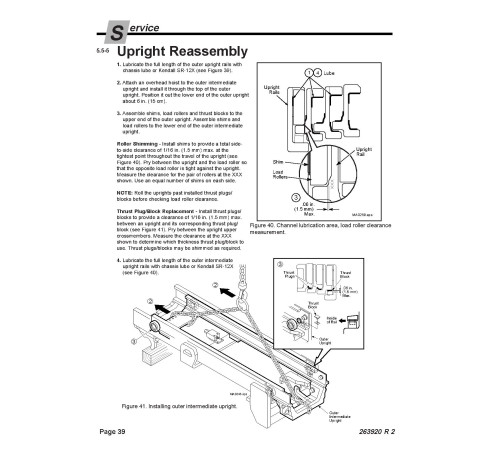

Triplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

SERVICE DATA

Maintenance Schedule

Maintenance Note

Tightening Torque for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Instructions

Special Service Tools

LIFT LINK TELEMATICS CONTROL UNIT

LIFT LINK TELEMATICS CONTROL UNIT

HOW TO READ CIRCUIT DIAGRAMS

Description of circuit diagrams

HOW TO READ CIRCUIT DIAGRAMS

HOW TO READ CONNECTOR DIAGRAMS

ABBREVIATION

CIRCUIT DIAGRAM

Circuit Diagram for D04EG Engine Model

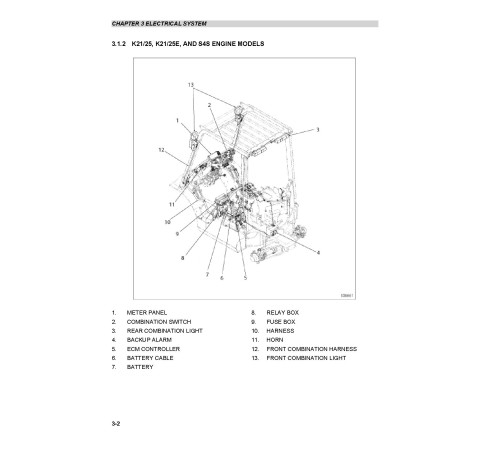

Circuit Diagram for K21/K25, K21/25E, and S4S Engine Models

Blank Page

3. Engine Technical Manual (EN-99789-70110_K21-K25_A0714)

Format: PDF, 214 pages

Language: English

Publication Date: 01 Jul 2014

Table of Contents:

How to use this manual

Description

Definition of Terms

Definition of Units

Description

Precautions for safety and quality

Reduction of Risk Operation

Correct Operation

Precautions for Radio Equipment Installation

Precautions

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Special Service Tools

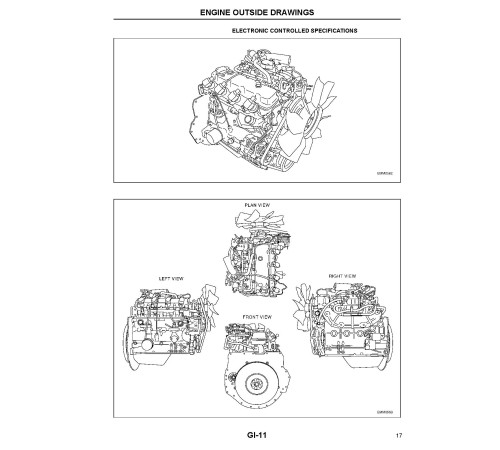

Engine outside drawings

MAIN SPECIFICATIONS

Standard and repair limit

STAMPED LOCATION OF ENGINE NO.

Trouble diagnosis

Engine Adjustment

Engine LPG Fuel System

Engine maintenance

Specifications

Tightening Torque

Maintenance Schedule

Oil and Grease, and Capacity

On Board Inspection and Service

Specifications

Tightening torque

Trouble diagnosis

ENGINE INSPECTION AND ADJUSTMENT

Engine Body Related

Ignition and Fuel Systems

SERVICE DATA AND SPECIFICATIONS (SDS)

Electronic Control System Specifications

Precautions

Precautions for Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

ENGINE OUTSIDE DRAWINGS

MAIN SPECIFICATIONS

ADJUSTMENT value

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Trouble diagnosis

Special Service Tools

Removal and installation of engine

Removal

Installation

Inspection

Engine service

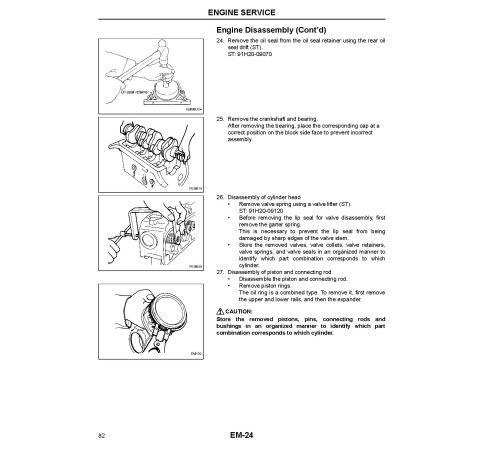

Engine Disassembly

Inspection and Correction

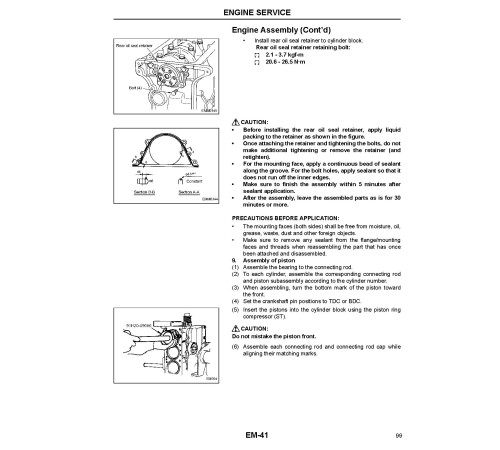

Engine Assembly

Engine Assembly (Cont’d)

Precautions

On Board Diagnostic (OBD) System of Engine

Precaution

Preparation

preparation

Special Service Tools

Description

Description

trouble diagnosis

Component Parts Location

ECM Component

Circuit Diagram

ECM Terminal

Trouble Diagnosis

How to Proceed with Trouble Diagnosis

Diagnosis Chart by Symptom

Description

Fail-Safe Function

Table of DTC

Service Tool

Self-Diagnosis Function (Without Service tool)

ECM Input/Output Monitor

ECM Active Test

Basic inspection

Inspection of Idle Speed and Ignition Timing

Throttle Valve Closed Position Learning and Idle Air Volume Learning

Accelerator Pedal Released Position Learning

Fuel Pressure Inspection

Fuel Pressure Release

COMPONENT PARTS INSPECTION

Crankshaft Position Sensor (POS)

Camshaft Position Sensor (PHASE)

Mass Air Flow Sensor

Engine Coolant Temperature Sensor

Throttle Position Sensor 1, 2 (Electric throttle control actuator assembly)

Component Parts Inspection

Accelerator Pedal Position Sensors 1, 2 (Accelerator work unit)

Intake Air Temperature Sensor (Joined with mass air flow sensor)

Stop Lamp Switch

Spark Plug

Ignition Coil

Injector

Fuel Pump

Electric Throttle Control Motor (Electric throttle control actuator assembly)

Heated Oxygen Sensor

Map Sensor (Atmosphere Pressure Sensor)

LPG Injector

LPG Assistance Injector

PTC Heater (Integrated with vaporizer)

pcv gas recirculation devi

System Diagram

Component Parts Inspection

ECM components

Removal and Installation

Lubrication system

Specifications

Adjustment Value

Oil Pressure

Tightening Torque

Trouble Diagnosis

Lubrication Schematic Diagram

Oil Pump

Engine coolant system

Specifications

Adjustment Value

Tightening Torque

Trouble Diagnosis

Cooling System Configuration

Water Pump

Thermostat

Emission control system

ENGINE OUTSIDE DRAWINGS

SYSTEM DIAGRAM

UNIT LAYOUT

LPG FUEL SYSTEM TROUBLE DIAGNOSIS

DISASSEMBLY AND ASSEMBLY OF FUEL SYSTEM

Removal and Installation of Electronic Control Throttle Assembly

Removal and Installation of Gasoline Fuel Injector (Electronic Controlled Gasoline and Combined Use)

LPG device (Specifications for LPG and combined use)

Vaporizer Mechanism and Operation

DISASSEMBLY AND ASSEMBLY OF INJECTOR HOLDER

LPG Fuel Injector

LPG Assist Fuel Injector

LPG Fuel Pressure Sensor

Relief Valve (2 Relief Valves)

DISASSEMBLY AND ASSEMBLY OF VAPORIZER

Tar drain, Removal, Installation, Disassem- bly and Inspection of Vaporizer

Adjustment value

Trouble diagnosis

Starter motor

Specifications

Components

Component Parts Location

Overhaul

Assembly Inspection

ALTERNATOR

Components of Alternator

Disassembly

Inspection

4. Wiring Diagram (EL-X0024043-00)

Format: PDF, 1 page

Language: English

5. Wiring Diagram (EL-99719-7M110s)

Format: PDF, 7 pages

Language: English

6. Wiring Diagram (EL-99719-7M100s)

Format: PDF, 7 pages

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing engine, and troubleshooting for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FG15NM (AF34B-00012-49999)

FG18NM (AF34B-00012-49999)

FG20CNM (AF34B-50012-99999)

FG20NM (AF17F-00012-49999)

FG25NM (AF17F-00012-49999)

FG28NM (AF36B-00012-49999)

FG30NM (AF13H-00012-49999)

FG33NM (AF13H-50012-99999)

FG35NM (AF13H-50012-99999)

The manual comprises 6 documents, including the Fault Codes List, Service Manual, Engine Technical Manual, and three Wiring Diagrams

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual (SM-99729-70100_A17)

Format: PDF, 710 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Truck Models Covered

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Removal and Installation

Inspection and Adjustment

ELECTRICAL SYSTEM

Chassis Electrical Components and Wiring Outline

Console Box

Main Electrical Components

Battery Maintenance

Meter Panel

Wire Color

Troubleshooting

CONTROLLERS

Outline

Main Functions

Service Tool Functions

Mast Interlock System

Driving Interlock System

Seat Belt Warning Icon

Parking Brake Warning Alarm and Icon

Harness Codes

Truck Status Display and Troubleshooting

POWER TRAIN

Removal and Installation (MC Models)

Removal and Installation (FC Models)

POWERSHIFT TRANSMISSION

Structure and Functions

Removal and Installation

Outline

Powershift Transmission, Disassembly

Powershift Transmission, Assembly

Control Valve, Disassembly

Control Valve, Assembly

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removal and Installation

Disassembly and Assembly

Troubleshooting

Service Data

REAR AXLE

Structure and Functions

Removal and Installation

Disassembly and Assembly

BRAKE SYSTEM

Structure

Disassembly and Assembly

Inspection and Adjustment

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembly and Assembly

Steering Valve

Troubleshooting

Service Data

HYDRAULIC SYSTEM

Structure and Functions

Disassembly and Reassembly

Inspection and Adjustment

Troubleshooting

Service Data

MC Control Valve

FC Control Valve

MAST AND FORKS

Simplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Duplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Triplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

SERVICE DATA

Maintenance Schedule

Maintenance Note

Tightening Torque for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Instructions

Special Service Tools

LIFT LINK TELEMATICS CONTROL UNIT

LIFT LINK TELEMATICS CONTROL UNIT

HOW TO READ CIRCUIT DIAGRAMS

Description of circuit diagrams

HOW TO READ CIRCUIT DIAGRAMS

HOW TO READ CONNECTOR DIAGRAMS

ABBREVIATION

CIRCUIT DIAGRAM

Circuit Diagram for D04EG Engine Model

Circuit Diagram for K21/K25, K21/25E, and S4S Engine Models

Blank Page

3. Engine Technical Manual (EN-99789-70110_K21-K25_A0714)

Format: PDF, 214 pages

Language: English

Publication Date: 01 Jul 2014

Table of Contents:

How to use this manual

Description

Definition of Terms

Definition of Units

Description

Precautions for safety and quality

Reduction of Risk Operation

Correct Operation

Precautions for Radio Equipment Installation

Precautions

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Special Service Tools

Engine outside drawings

MAIN SPECIFICATIONS

Standard and repair limit

STAMPED LOCATION OF ENGINE NO.

Trouble diagnosis

Engine Adjustment

Engine LPG Fuel System

Engine maintenance

Specifications

Tightening Torque

Maintenance Schedule

Oil and Grease, and Capacity

On Board Inspection and Service

Specifications

Tightening torque

Trouble diagnosis

ENGINE INSPECTION AND ADJUSTMENT

Engine Body Related

Ignition and Fuel Systems

SERVICE DATA AND SPECIFICATIONS (SDS)

Electronic Control System Specifications

Precautions

Precautions for Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

ENGINE OUTSIDE DRAWINGS

MAIN SPECIFICATIONS

ADJUSTMENT value

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Trouble diagnosis

Special Service Tools

Removal and installation of engine

Removal

Installation

Inspection

Engine service

Engine Disassembly

Inspection and Correction

Engine Assembly

Engine Assembly (Cont’d)

Precautions

On Board Diagnostic (OBD) System of Engine

Precaution

Preparation

preparation

Special Service Tools

Description

Description

trouble diagnosis

Component Parts Location

ECM Component

Circuit Diagram

ECM Terminal

Trouble Diagnosis

How to Proceed with Trouble Diagnosis

Diagnosis Chart by Symptom

Description

Fail-Safe Function

Table of DTC

Service Tool

Self-Diagnosis Function (Without Service tool)

ECM Input/Output Monitor

ECM Active Test

Basic inspection

Inspection of Idle Speed and Ignition Timing

Throttle Valve Closed Position Learning and Idle Air Volume Learning

Accelerator Pedal Released Position Learning

Fuel Pressure Inspection

Fuel Pressure Release

COMPONENT PARTS INSPECTION

Crankshaft Position Sensor (POS)

Camshaft Position Sensor (PHASE)

Mass Air Flow Sensor

Engine Coolant Temperature Sensor

Throttle Position Sensor 1, 2 (Electric throttle control actuator assembly)

Component Parts Inspection

Accelerator Pedal Position Sensors 1, 2 (Accelerator work unit)

Intake Air Temperature Sensor (Joined with mass air flow sensor)

Stop Lamp Switch

Spark Plug

Ignition Coil

Injector

Fuel Pump

Electric Throttle Control Motor (Electric throttle control actuator assembly)

Heated Oxygen Sensor

Map Sensor (Atmosphere Pressure Sensor)

LPG Injector

LPG Assistance Injector

PTC Heater (Integrated with vaporizer)

pcv gas recirculation devi

System Diagram

Component Parts Inspection

ECM components

Removal and Installation

Lubrication system

Specifications

Adjustment Value

Oil Pressure

Tightening Torque

Trouble Diagnosis

Lubrication Schematic Diagram

Oil Pump

Engine coolant system

Specifications

Adjustment Value

Tightening Torque

Trouble Diagnosis

Cooling System Configuration

Water Pump

Thermostat

Emission control system

ENGINE OUTSIDE DRAWINGS

SYSTEM DIAGRAM

UNIT LAYOUT

LPG FUEL SYSTEM TROUBLE DIAGNOSIS

DISASSEMBLY AND ASSEMBLY OF FUEL SYSTEM

Removal and Installation of Electronic Control Throttle Assembly

Removal and Installation of Gasoline Fuel Injector (Electronic Controlled Gasoline and Combined Use)

LPG device (Specifications for LPG and combined use)

Vaporizer Mechanism and Operation

DISASSEMBLY AND ASSEMBLY OF INJECTOR HOLDER

LPG Fuel Injector

LPG Assist Fuel Injector

LPG Fuel Pressure Sensor

Relief Valve (2 Relief Valves)

DISASSEMBLY AND ASSEMBLY OF VAPORIZER

Tar drain, Removal, Installation, Disassem- bly and Inspection of Vaporizer

Adjustment value

Trouble diagnosis

Starter motor

Specifications

Components

Component Parts Location

Overhaul

Assembly Inspection

ALTERNATOR

Components of Alternator

Disassembly

Inspection

4. Wiring Diagram (EL-X0024043-00)

Format: PDF, 1 page

Language: English

5. Wiring Diagram (EL-99719-7M110s)

Format: PDF, 7 pages

Language: English

6. Wiring Diagram (EL-99719-7M100s)

Format: PDF, 7 pages

Language: English

Included

Fault Codes List

1Service Manual

2Engine Technical Manual

1Wiring Diagram

3Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары