$49.99

Fault Codes List

1Service Manual

2Engine Technical Manual

1Operate and Maintenance manual

1Wiring Diagram

1Illustrated factory set of Service Manuals for Mitsubishi Diesel Forklift Trucks Models FD40N (AF12B-00011-up), FD45N (AF19D-50001-up), FD50CN (AF19D-80001-up), FD50N (AF28C-50001-up) and FD55N (AF28C-80001-up).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing engine, operating, maintaining, and troubleshooting for your diesel forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FD40N (AF12B-00011-up)

FD45N (AF19D-50001-up)

FD50CN (AF19D-80001-up)

FD50N (AF28C-50001-up)

FD55N (AF28C-80001-up)

The manual comprises 8 documents, including the Fault Codes List, two Service Manuals, Engine Technical Manual, Operate and Maintenance manual, Wiring Diagram, and two Special Instructions

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: Chassis & Mast (SM-99739-79120_A0115)

Format: PDF, 561 pages

Language: English

Table of Contents:

CHAPTER INDEX

GENERAL INFORMATION

COOLING SYSTEM

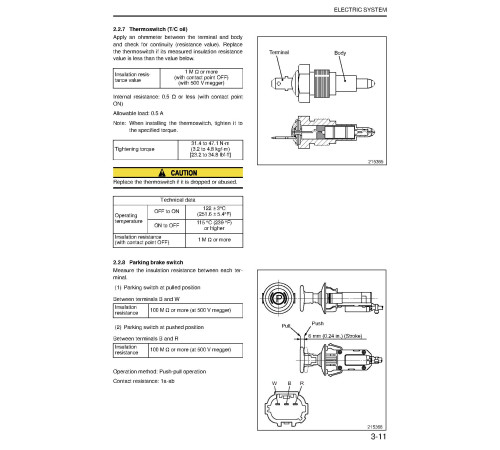

ELECTRIC SYSTEM

CONTROLLERS

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE AND REDUCTION DIFFERENTIAL

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

SERVICE DATA

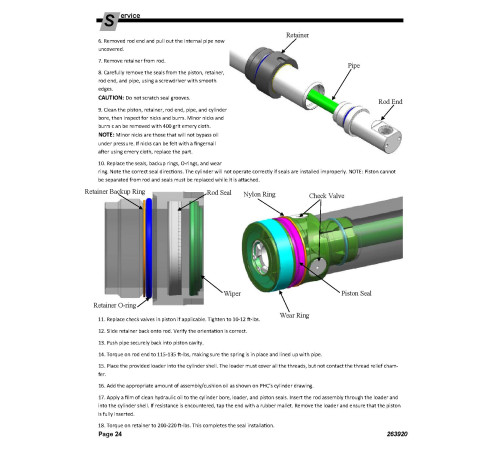

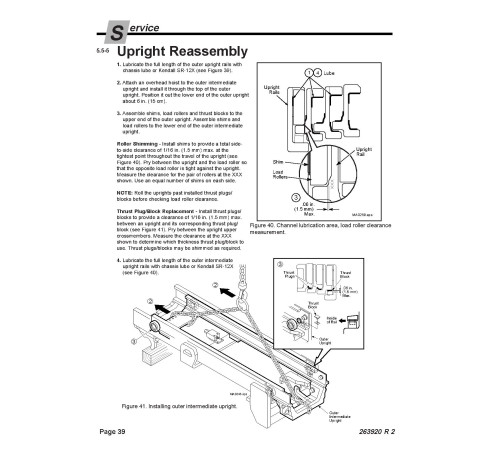

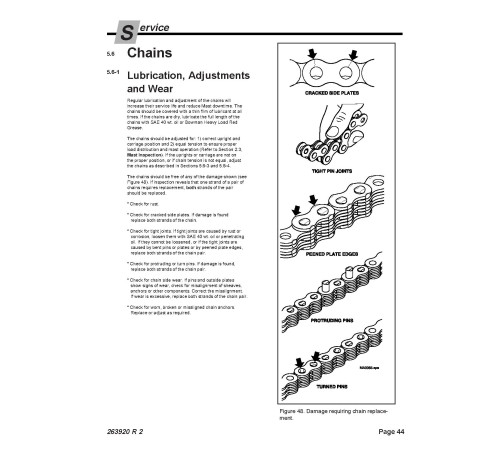

3. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

4. Engine Technical Manual: S6S Diesel Engine (EN-99739-12110_S6S_0313)

Format: PDF, 206 pages

Language: English

Table of Contents:

GENERAL

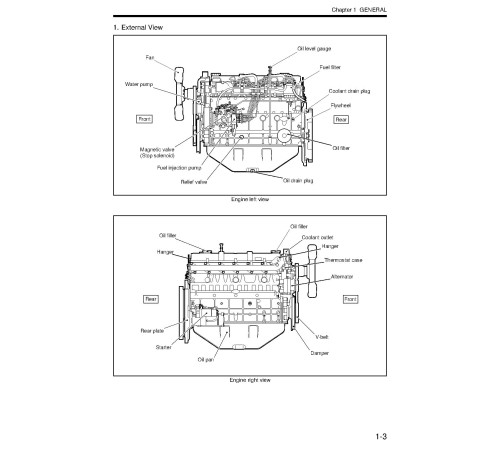

External View

System flow diagrams

Engine serial number location

Main specifications

SERVICE DATA

Maintenance service data

Tightening torque table

SERVICE TOOLS

Special tools

OVERHAUL INSTRUCTIONS

Determining overhaul timing

Compression pressure - Measure

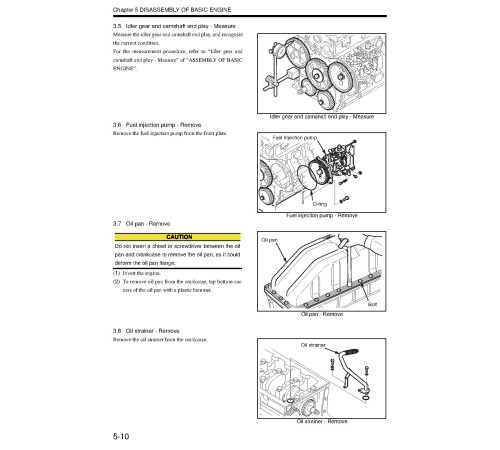

DISASSEMBLY OF BASIC ENGINE

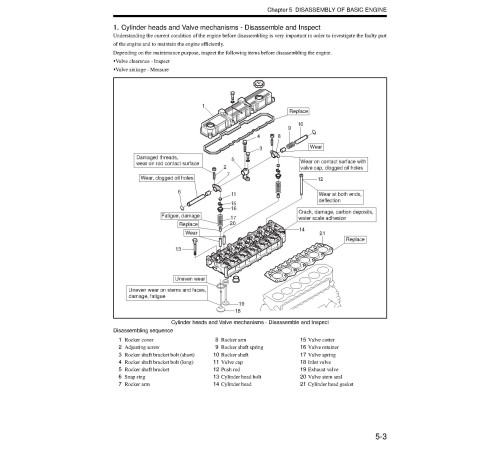

Cylinder heads and Valve mechanisms - Disassemble and Inspect

Rear equipment - Disassemble and Inspect

Front equipment - Disassemble and Inspect

Piston, Connecting rod, Crankshaft and Crankcase - Disassemble and Inspect

INSPECTION AND REPAIR OF BASIC ENGINE

Cylinder head and Valve mechanism - Inspect and Repair

Rear equipment - Inspect and Repair

Front equipment - Inspect and Repair

Piston and Connecting rod - Inspect and Repair

Crankcase and Crankshaft - Inspect and Repair

ASSEMBLY OF BASIC ENGINE

Piston, Connecting rod, Crankshaft and Crankcase - Assemble

Front equipment - Assemble

Rear equipment - Assemble

Cylinder head and Valve mechanism - Assemble

FUEL SYSTEM

Fuel system - Remove

Fuel system - Disassemble, Inspect and Assemble

Fuel system - Install

LUBRICATION SYSTEM

Lubrication system - Remove

Lubrication system - Disassemble, Inspect and Assemble

Lubrication system - Install

COOLING SYSTEM

Cooling system - Remove

Cooling system - Disassemble, Inspect and Assemble

Cooling system - Install

INLET AND EXHAUST SYSTEMS

Inlet and exhaust systems - Remove

Inlet and exhaust systems - Disassemble, Inspect and Assemble

Inlet and exhaust systems - Install

ELECTRICAL SYSTEM

Electrical system - Remove and Inspect

Electrical system - Disassemble, Inspect and Assemble

Electrical system - Install

ADJUSTMENT AND OPERATION

Engine - Adjust

Break-in operation

Performance test

TECHNICAL PUBLICATIONS FEEDBACK

Back cover

Rear cover

5. Operate and Maintenance manual (OMM-99730-79120_A1114)

Format: PDF, 234 pages

Language: English

Table of Contents:

SAFETY RULES FOR LIFT TRUCK OPERATORS

General

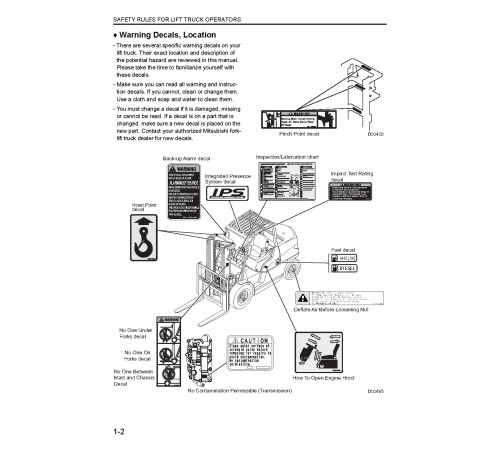

Warning Decals, Location

Decals for LPG Fuel and Dual Fuel Only

Warning Decals, Description

Safety Rules

Operating Precautions

Working Precautions

LP-Gas

KNOW YOUR LIFT TRUCK

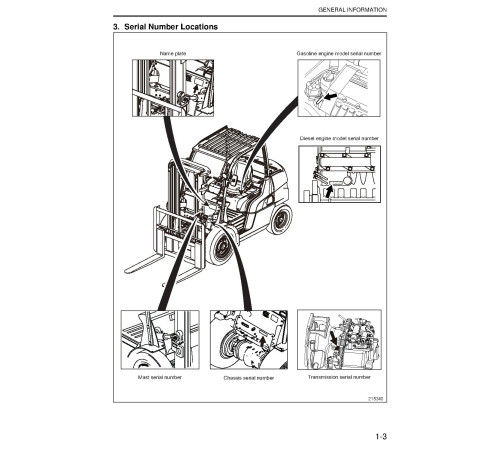

Serial Number and Capacity Plate

Electrical Components

Model View

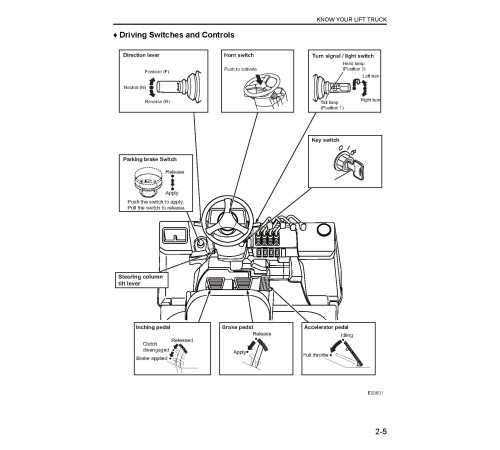

Driving Switches and Controls

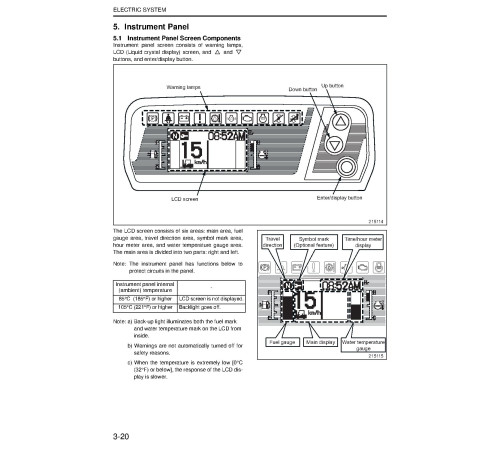

Instrument Panel

Integrated Presence System (IPS)

Parking Brake Dragging Warning

Operating Switches and Controls

Operator Seat

Seat Belt

Fork Locking Pins

Changing Forks

Drawbar Pin (If Equipped)

Assist Grip

Engine Hood

Hydraulic Tank Oil Level / Filler Hole

Fuel Filler

Fuel Shut-off Valve

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What Lift Truck Stability Is

Center of Gravity (CG)

Stability and Center of Gravity (Top View)

Stability and Center of Gravity (Side View)

Lift Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

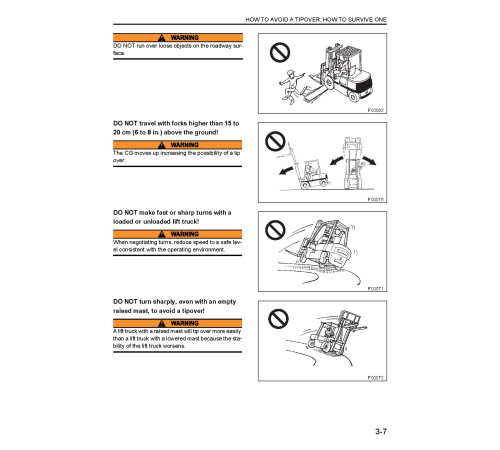

Dos and Donts to Avoid Tipover

How to Survive in a Tipover

REFUELING

Gasoline and Diesel Engine Equipped

LP-Gas Equipped

OPERATION

New Lift Truck Break-in

Before Starting Engine

Starting Gasoline Engine

Starting LP-Gas Engine

Starting Diesel Engine

Engine Won't Start

After Starting Engine

Before Moving Lift Truck

Lift Truck Operation

Stopping Lift Truck

Parking Lift Truck (After Stopping)

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Correct Operating Steps

Incorrect Operating Steps

Inching Into and Lifting the Load

Traveling With the Load

Unloading

Working on Grades

STORING THE LIFT TRUCK

End of Each Shift Storage

Long Term Storage

TRANSPORTATION HINTS

Lift Truck Loading and Shipping

Lift Truck Lifting and Tiedown Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

Severe Dust or Lint Conditions

TROUBLESHOOTING

Stalled Engine

Starting With Jumper Cables

If Lamps Won't Glow

If the Engine CoolantTemperature Gauge Shows Red Zone

If Torque Converter Oil Temperature Warning Lamp Glows (Powershift)

Trouble With the LP-Gas Equipment

If the Lift Truck Won't Change Directions

If the Lift Truck Won't Move

If the Mast Stops Moving

If a Tire Blows out

Changing Tires

Changing Dual Tires (Optional)

Rear Tire

Error Codes and Explanations

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

Parts to Be Changed Periodically

SERVICE DATA

Fuel Information

Coolant Information

Recommended Fuels and Oils

Specifications (Standard Models)

Refill Capacities

TO THE MITSUBISHI FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Proper Disposal of Your Lift Truck

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report for Mitsubishi Caterpillar Forklift America Inc. Customers Only

INDEX

Blank Page

6. Wiring Diagram (EL-X0025376)

Format: PDF, 2 pages

Language: English

7. Special Instruction: Diagnostic Trouble Code DTC-F88 (M-DTC-F88)

Format: PDF, 17 pages

Language: English

8. Special Instruction: Diagnostic Trouble Code DTC F-85, F-87, F-93 (M-DTC-F85_F87-F93)

Format: PDF, 20 pages

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, repairing engine, operating, maintaining, and troubleshooting for your diesel forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FD40N (AF12B-00011-up)

FD45N (AF19D-50001-up)

FD50CN (AF19D-80001-up)

FD50N (AF28C-50001-up)

FD55N (AF28C-80001-up)

The manual comprises 8 documents, including the Fault Codes List, two Service Manuals, Engine Technical Manual, Operate and Maintenance manual, Wiring Diagram, and two Special Instructions

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: Chassis & Mast (SM-99739-79120_A0115)

Format: PDF, 561 pages

Language: English

Table of Contents:

CHAPTER INDEX

GENERAL INFORMATION

COOLING SYSTEM

ELECTRIC SYSTEM

CONTROLLERS

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE AND REDUCTION DIFFERENTIAL

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

SERVICE DATA

3. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

4. Engine Technical Manual: S6S Diesel Engine (EN-99739-12110_S6S_0313)

Format: PDF, 206 pages

Language: English

Table of Contents:

GENERAL

External View

System flow diagrams

Engine serial number location

Main specifications

SERVICE DATA

Maintenance service data

Tightening torque table

SERVICE TOOLS

Special tools

OVERHAUL INSTRUCTIONS

Determining overhaul timing

Compression pressure - Measure

DISASSEMBLY OF BASIC ENGINE

Cylinder heads and Valve mechanisms - Disassemble and Inspect

Rear equipment - Disassemble and Inspect

Front equipment - Disassemble and Inspect

Piston, Connecting rod, Crankshaft and Crankcase - Disassemble and Inspect

INSPECTION AND REPAIR OF BASIC ENGINE

Cylinder head and Valve mechanism - Inspect and Repair

Rear equipment - Inspect and Repair

Front equipment - Inspect and Repair

Piston and Connecting rod - Inspect and Repair

Crankcase and Crankshaft - Inspect and Repair

ASSEMBLY OF BASIC ENGINE

Piston, Connecting rod, Crankshaft and Crankcase - Assemble

Front equipment - Assemble

Rear equipment - Assemble

Cylinder head and Valve mechanism - Assemble

FUEL SYSTEM

Fuel system - Remove

Fuel system - Disassemble, Inspect and Assemble

Fuel system - Install

LUBRICATION SYSTEM

Lubrication system - Remove

Lubrication system - Disassemble, Inspect and Assemble

Lubrication system - Install

COOLING SYSTEM

Cooling system - Remove

Cooling system - Disassemble, Inspect and Assemble

Cooling system - Install

INLET AND EXHAUST SYSTEMS

Inlet and exhaust systems - Remove

Inlet and exhaust systems - Disassemble, Inspect and Assemble

Inlet and exhaust systems - Install

ELECTRICAL SYSTEM

Electrical system - Remove and Inspect

Electrical system - Disassemble, Inspect and Assemble

Electrical system - Install

ADJUSTMENT AND OPERATION

Engine - Adjust

Break-in operation

Performance test

TECHNICAL PUBLICATIONS FEEDBACK

Back cover

Rear cover

5. Operate and Maintenance manual (OMM-99730-79120_A1114)

Format: PDF, 234 pages

Language: English

Table of Contents:

SAFETY RULES FOR LIFT TRUCK OPERATORS

General

Warning Decals, Location

Decals for LPG Fuel and Dual Fuel Only

Warning Decals, Description

Safety Rules

Operating Precautions

Working Precautions

LP-Gas

KNOW YOUR LIFT TRUCK

Serial Number and Capacity Plate

Electrical Components

Model View

Driving Switches and Controls

Instrument Panel

Integrated Presence System (IPS)

Parking Brake Dragging Warning

Operating Switches and Controls

Operator Seat

Seat Belt

Fork Locking Pins

Changing Forks

Drawbar Pin (If Equipped)

Assist Grip

Engine Hood

Hydraulic Tank Oil Level / Filler Hole

Fuel Filler

Fuel Shut-off Valve

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What Lift Truck Stability Is

Center of Gravity (CG)

Stability and Center of Gravity (Top View)

Stability and Center of Gravity (Side View)

Lift Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

Dos and Donts to Avoid Tipover

How to Survive in a Tipover

REFUELING

Gasoline and Diesel Engine Equipped

LP-Gas Equipped

OPERATION

New Lift Truck Break-in

Before Starting Engine

Starting Gasoline Engine

Starting LP-Gas Engine

Starting Diesel Engine

Engine Won't Start

After Starting Engine

Before Moving Lift Truck

Lift Truck Operation

Stopping Lift Truck

Parking Lift Truck (After Stopping)

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Correct Operating Steps

Incorrect Operating Steps

Inching Into and Lifting the Load

Traveling With the Load

Unloading

Working on Grades

STORING THE LIFT TRUCK

End of Each Shift Storage

Long Term Storage

TRANSPORTATION HINTS

Lift Truck Loading and Shipping

Lift Truck Lifting and Tiedown Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

Severe Dust or Lint Conditions

TROUBLESHOOTING

Stalled Engine

Starting With Jumper Cables

If Lamps Won't Glow

If the Engine CoolantTemperature Gauge Shows Red Zone

If Torque Converter Oil Temperature Warning Lamp Glows (Powershift)

Trouble With the LP-Gas Equipment

If the Lift Truck Won't Change Directions

If the Lift Truck Won't Move

If the Mast Stops Moving

If a Tire Blows out

Changing Tires

Changing Dual Tires (Optional)

Rear Tire

Error Codes and Explanations

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

Parts to Be Changed Periodically

SERVICE DATA

Fuel Information

Coolant Information

Recommended Fuels and Oils

Specifications (Standard Models)

Refill Capacities

TO THE MITSUBISHI FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Proper Disposal of Your Lift Truck

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report for Mitsubishi Caterpillar Forklift America Inc. Customers Only

INDEX

Blank Page

6. Wiring Diagram (EL-X0025376)

Format: PDF, 2 pages

Language: English

7. Special Instruction: Diagnostic Trouble Code DTC-F88 (M-DTC-F88)

Format: PDF, 17 pages

Language: English

8. Special Instruction: Diagnostic Trouble Code DTC F-85, F-87, F-93 (M-DTC-F85_F87-F93)

Format: PDF, 20 pages

Language: English

Included

Fault Codes List

1Service Manual

2Engine Technical Manual

1Operate and Maintenance manual

1Wiring Diagram

1Special Instruction

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары