Illustrated factory set of Service Manuals for Mitsubishi Diesel Forklift Trucks Models FD20NM (AF18D-00012-49999), FD25NM (AF18D-00012-49999), FD28NM (AF37A-00012-49999), FD30NM (AF14F-00012-49999), FD33NM (AF14F-50012-99999) and FD35NM (AF14F-50012-99999).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, and repairing engine for your diesel forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

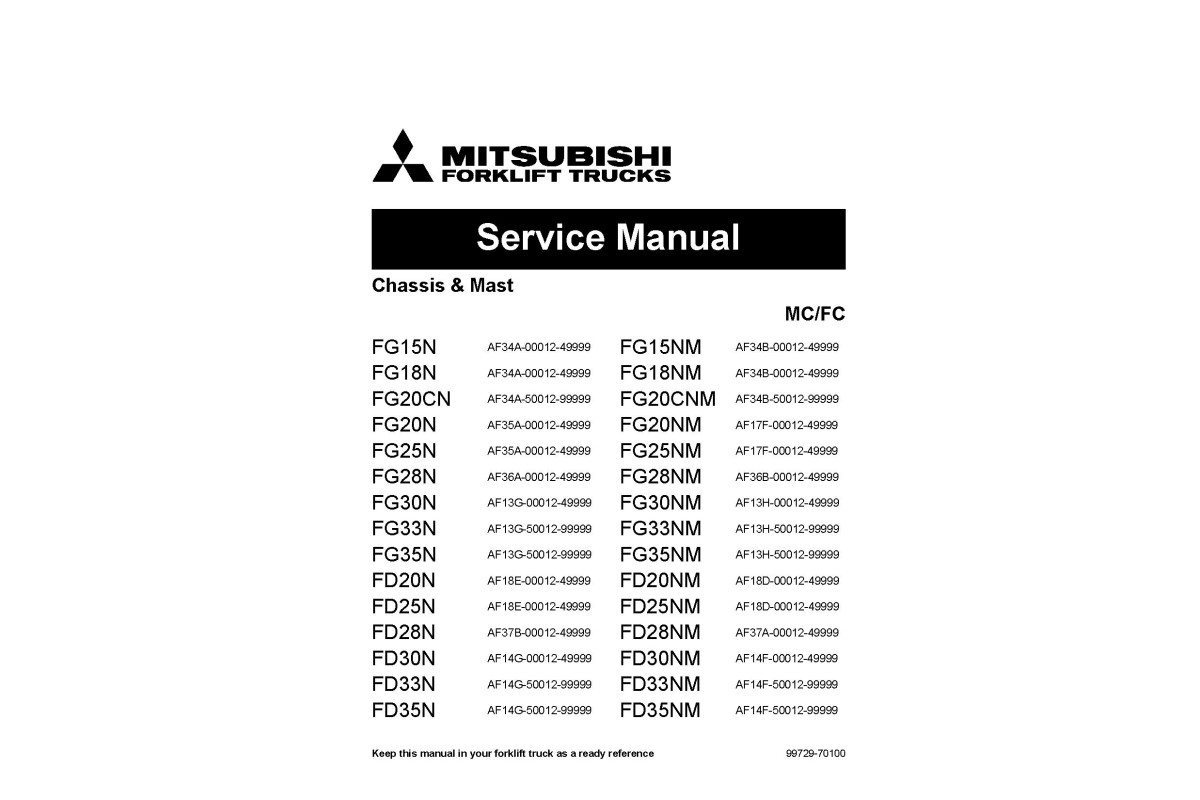

Covered Models:

FD20NM (AF18D-00012-49999)

FD25NM (AF18D-00012-49999)

FD28NM (AF37A-00012-49999)

FD30NM (AF14F-00012-49999)

FD33NM (AF14F-50012-99999)

FD35NM (AF14F-50012-99999)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Engine Technical Manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

3. Service Manual (SM-99729-70100_A17)

Format: PDF, 710 pages

Language: English

Table of Contents:

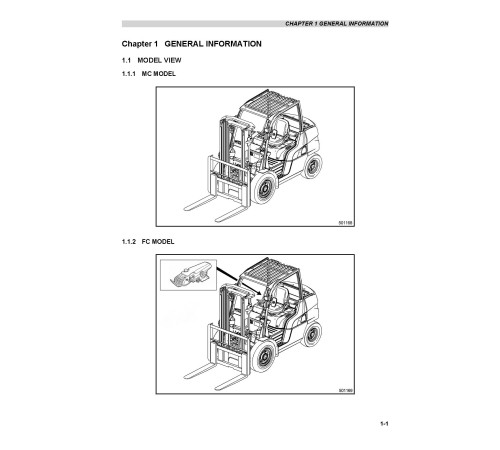

GENERAL INFORMATION

Model View

Truck Models Covered

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Removal and Installation

Inspection and Adjustment

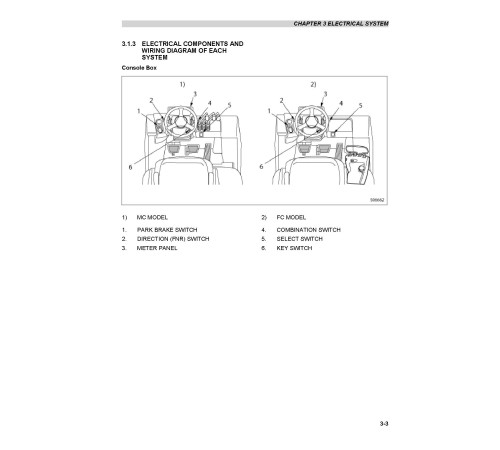

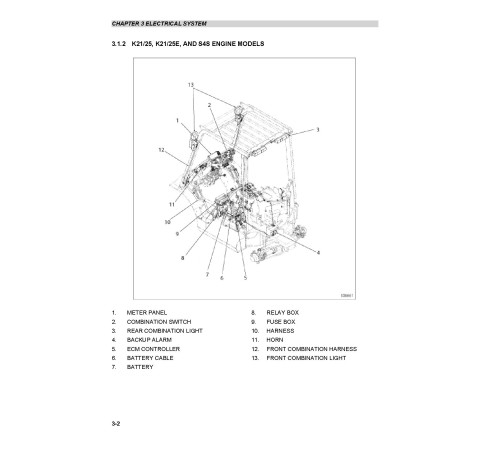

ELECTRICAL SYSTEM

Chassis Electrical Components and Wiring Outline

Console Box

Main Electrical Components

Battery Maintenance

Meter Panel

Wire Color

Troubleshooting

CONTROLLERS

Outline

Main Functions

Service Tool Functions

Mast Interlock System

Driving Interlock System

Seat Belt Warning Icon

Parking Brake Warning Alarm and Icon

Harness Codes

Truck Status Display and Troubleshooting

POWER TRAIN

Removal and Installation (MC Models)

Removal and Installation (FC Models)

POWERSHIFT TRANSMISSION

Structure and Functions

Removal and Installation

Outline

Powershift Transmission, Disassembly

Powershift Transmission, Assembly

Control Valve, Disassembly

Control Valve, Assembly

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removal and Installation

Disassembly and Assembly

Troubleshooting

Service Data

REAR AXLE

Structure and Functions

Removal and Installation

Disassembly and Assembly

BRAKE SYSTEM

Structure

Disassembly and Assembly

Inspection and Adjustment

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembly and Assembly

Steering Valve

Troubleshooting

Service Data

HYDRAULIC SYSTEM

Structure and Functions

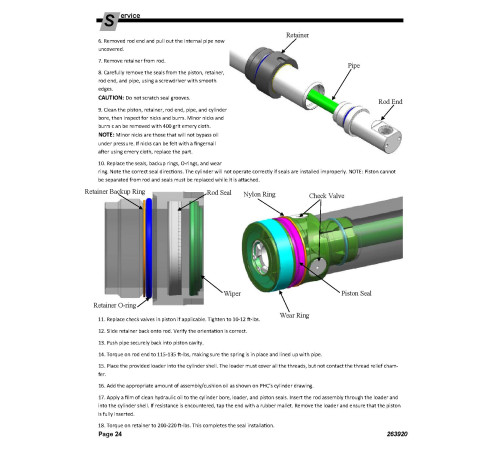

Disassembly and Reassembly

Inspection and Adjustment

Troubleshooting

Service Data

MC Control Valve

FC Control Valve

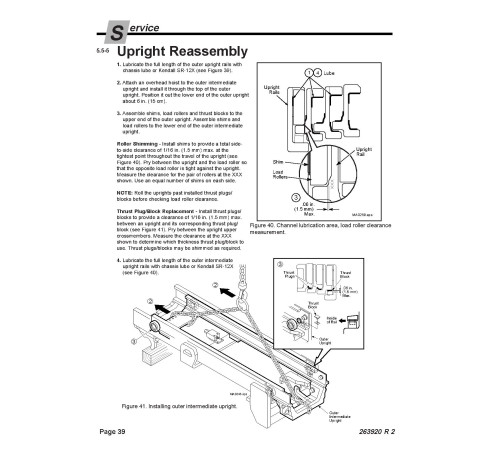

MAST AND FORKS

Simplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Duplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Triplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

SERVICE DATA

Maintenance Schedule

Maintenance Note

Tightening Torque for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Instructions

Special Service Tools

LIFT LINK TELEMATICS CONTROL UNIT

LIFT LINK TELEMATICS CONTROL UNIT

HOW TO READ CIRCUIT DIAGRAMS

Description of circuit diagrams

HOW TO READ CIRCUIT DIAGRAMS

HOW TO READ CONNECTOR DIAGRAMS

ABBREVIATION

CIRCUIT DIAGRAM

Circuit Diagram for D04EG Engine Model

Circuit Diagram for K21/K25, K21/25E, and S4S Engine Models

Blank Page

4. Engine Technical Manual (EN-99729-77120_S4S)

Format: PDF, 188 pages

Language: English

Table of Contents:

INTRODUCTION

How to use this manual

Safety Cautions

GENERAL CONTENTS

GENERAL

External view

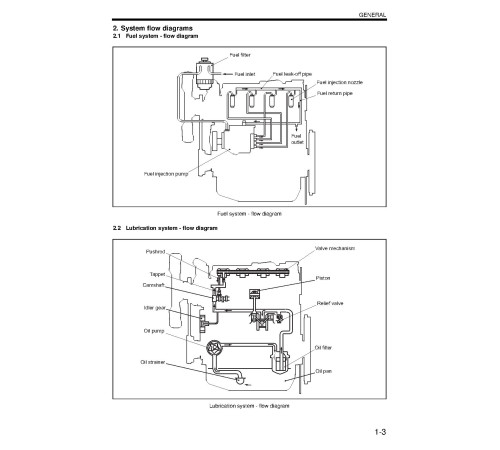

System flow diagrams

Engine serial number location

Main specifications

Tips on disassembling and reassembling

SERVICE DATA

Maintenance service data

Tightening torque table

SERVICE TOOLS

Special tool

DETERMINATION OF OVERHAUL

Determining overhaul timing

Testing compression pressure

DISASSEMBLY OF BASIC ENGINE

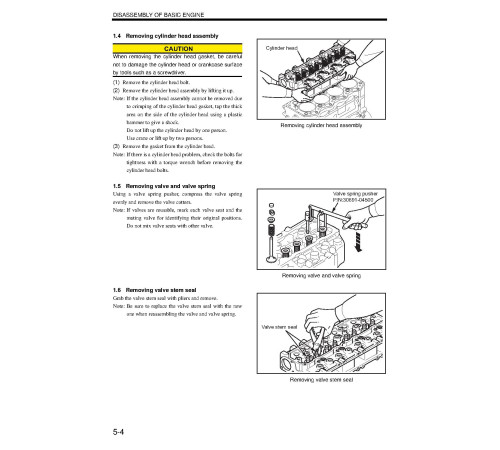

Disassembling and inspecting cylinder head and valve mechanism

Disassembling and inspecting flywheel

Disassembling and inspecting damper, gear case, timing gear and camshaft

Disassembling and inspecting piston, connecting rod, crankshaft and crankcase

INSPECTION AND REPAIR OF BASIC ENGINE

Inspecting and repairing cylinder head and valve mechanism

Inspecting and repairing flywheel

Inspecting and repairing timing gear and camshaft

Inspecting and repairing piston, connecting rod, crankshaft and crankcase

REASSEMBLY OF BASIC ENGINE

Reassembling piston, connecting rod, crankshaft and crankcase

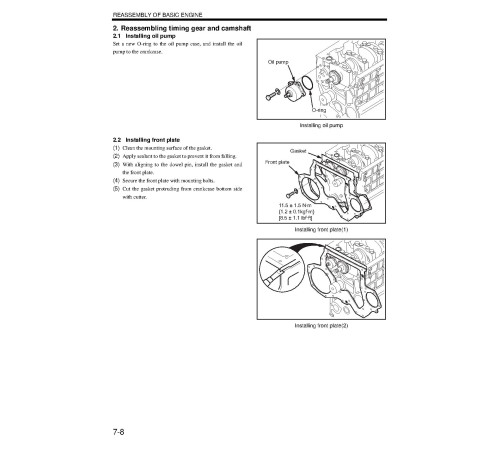

Reassembling timing gear and camshaft

Reassembling flywheel

Reassembling cylinder head and valve mechanism

FUEL SYSTEM

Removing fuel system

Disassembling, inspecting and reassembling fuel system

Installing fuel system

LUBRICATION SYSTEM

Removing lubrication system

Disassembling, inspecting and reassembling lubrication system

Installing lubrication system

COOLING SYSTEM

Removing cooling system

Disassembling, inspecting and reassembling cooling system

Installing cooling system

INLET AND EXHAUST SYSTEMS

Removing turbocharger, inlet and exhaust system

Disassembling, inspecting and reassembling inlet and exhaust systems

Installing inlet and exhaust systems

ELECTRICAL SYSTEM

Removing electrical system

Disassembling, inspecting and reassembling electrical system

Installing electrical system

ADJUSTMENT AND OPERATION

Adjusting engine

Break-in operation

Performance test (JIS standard)

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, and repairing engine for your diesel forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FD20NM (AF18D-00012-49999)

FD25NM (AF18D-00012-49999)

FD28NM (AF37A-00012-49999)

FD30NM (AF14F-00012-49999)

FD33NM (AF14F-50012-99999)

FD35NM (AF14F-50012-99999)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Engine Technical Manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

3. Service Manual (SM-99729-70100_A17)

Format: PDF, 710 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Truck Models Covered

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Removal and Installation

Inspection and Adjustment

ELECTRICAL SYSTEM

Chassis Electrical Components and Wiring Outline

Console Box

Main Electrical Components

Battery Maintenance

Meter Panel

Wire Color

Troubleshooting

CONTROLLERS

Outline

Main Functions

Service Tool Functions

Mast Interlock System

Driving Interlock System

Seat Belt Warning Icon

Parking Brake Warning Alarm and Icon

Harness Codes

Truck Status Display and Troubleshooting

POWER TRAIN

Removal and Installation (MC Models)

Removal and Installation (FC Models)

POWERSHIFT TRANSMISSION

Structure and Functions

Removal and Installation

Outline

Powershift Transmission, Disassembly

Powershift Transmission, Assembly

Control Valve, Disassembly

Control Valve, Assembly

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removal and Installation

Disassembly and Assembly

Troubleshooting

Service Data

REAR AXLE

Structure and Functions

Removal and Installation

Disassembly and Assembly

BRAKE SYSTEM

Structure

Disassembly and Assembly

Inspection and Adjustment

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembly and Assembly

Steering Valve

Troubleshooting

Service Data

HYDRAULIC SYSTEM

Structure and Functions

Disassembly and Reassembly

Inspection and Adjustment

Troubleshooting

Service Data

MC Control Valve

FC Control Valve

MAST AND FORKS

Simplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Duplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

Triplex Mast

Structure and Functions

Removal and Installation

Disassembly and Assembly

Removal and Installation of Mast Rollers and Strips without Removing Mast from Truck

Inspection and Adjustment

Troubleshooting

Service Data

SERVICE DATA

Maintenance Schedule

Maintenance Note

Tightening Torque for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Instructions

Special Service Tools

LIFT LINK TELEMATICS CONTROL UNIT

LIFT LINK TELEMATICS CONTROL UNIT

HOW TO READ CIRCUIT DIAGRAMS

Description of circuit diagrams

HOW TO READ CIRCUIT DIAGRAMS

HOW TO READ CONNECTOR DIAGRAMS

ABBREVIATION

CIRCUIT DIAGRAM

Circuit Diagram for D04EG Engine Model

Circuit Diagram for K21/K25, K21/25E, and S4S Engine Models

Blank Page

4. Engine Technical Manual (EN-99729-77120_S4S)

Format: PDF, 188 pages

Language: English

Table of Contents:

INTRODUCTION

How to use this manual

Safety Cautions

GENERAL CONTENTS

GENERAL

External view

System flow diagrams

Engine serial number location

Main specifications

Tips on disassembling and reassembling

SERVICE DATA

Maintenance service data

Tightening torque table

SERVICE TOOLS

Special tool

DETERMINATION OF OVERHAUL

Determining overhaul timing

Testing compression pressure

DISASSEMBLY OF BASIC ENGINE

Disassembling and inspecting cylinder head and valve mechanism

Disassembling and inspecting flywheel

Disassembling and inspecting damper, gear case, timing gear and camshaft

Disassembling and inspecting piston, connecting rod, crankshaft and crankcase

INSPECTION AND REPAIR OF BASIC ENGINE

Inspecting and repairing cylinder head and valve mechanism

Inspecting and repairing flywheel

Inspecting and repairing timing gear and camshaft

Inspecting and repairing piston, connecting rod, crankshaft and crankcase

REASSEMBLY OF BASIC ENGINE

Reassembling piston, connecting rod, crankshaft and crankcase

Reassembling timing gear and camshaft

Reassembling flywheel

Reassembling cylinder head and valve mechanism

FUEL SYSTEM

Removing fuel system

Disassembling, inspecting and reassembling fuel system

Installing fuel system

LUBRICATION SYSTEM

Removing lubrication system

Disassembling, inspecting and reassembling lubrication system

Installing lubrication system

COOLING SYSTEM

Removing cooling system

Disassembling, inspecting and reassembling cooling system

Installing cooling system

INLET AND EXHAUST SYSTEMS

Removing turbocharger, inlet and exhaust system

Disassembling, inspecting and reassembling inlet and exhaust systems

Installing inlet and exhaust systems

ELECTRICAL SYSTEM

Removing electrical system

Disassembling, inspecting and reassembling electrical system

Installing electrical system

ADJUSTMENT AND OPERATION

Adjusting engine

Break-in operation

Performance test (JIS standard)

Included

Fault Codes List

1Service Manual

2Engine Technical Manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары