Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FBC35N (A2BC4-60200-up), FBC40N (A2BC4-60200-up), FBC45N (A2BC4-60200-up) and FBC55N (A2BC5-60200-up).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC35N (A2BC4-60200-up)

FBC40N (A2BC4-60200-up)

FBC45N (A2BC4-60200-up)

FBC55N (A2BC5-60200-up)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Operate and Maintenance manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: GE SX Controls (SM-WENB8473-02-Controls)

Format: PDF, 143 pages

Language: English

3. Service Manual: Chassis & Mast (SM-WENB8472-01_07)

Format: PDF, 238 pages

Language: English

Table of Contents:

CHAPTER 1: GENERAL INFORMATION

Scope

Truck Models Covered

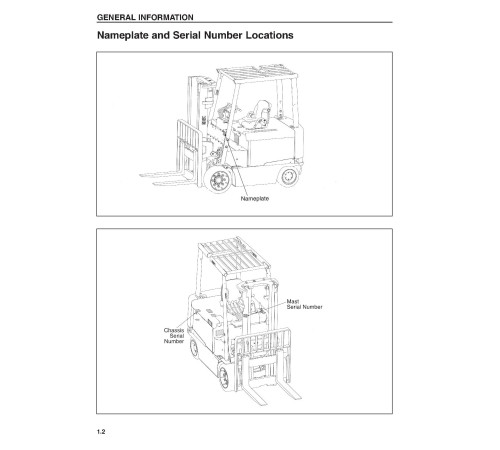

Nameplate and Serial Number Locations

Dimensions

Dimensions Chart

General Information (Standard Models)

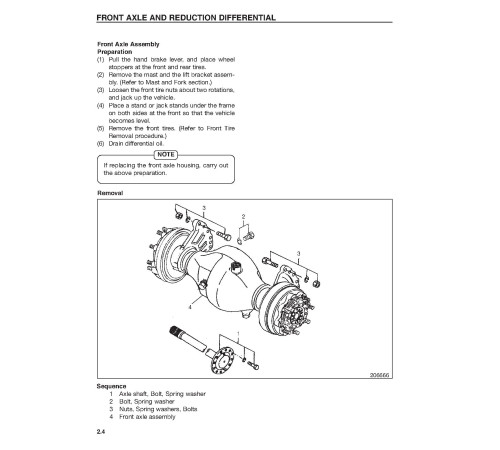

CHAPTER 2: FRONT AXLE AND REDUCTION DIFFERENTIAL

Specifications

Structure

Procedures and Key Points for Removal and Installation

Axle Shaft and Hub

Troubleshooting

Service Data

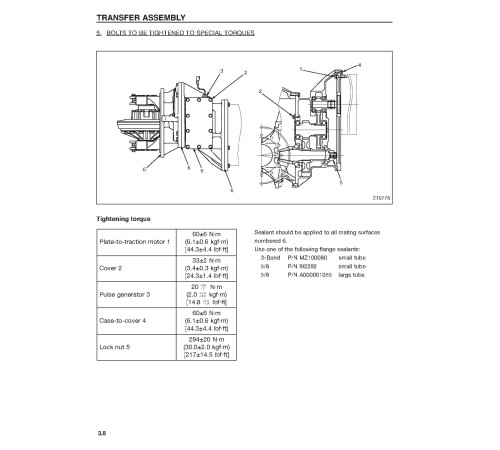

CHAPTER 3: TRANSFER ASSEMBLY

Structure and Functions

Disassembly and Reassembly

Tightening Torque

CHAPTER 4: REAR AXLE

Specifications

Structure

Procedures and Key Points for Removal and Installation

Rear Axle Assembly

Steering Cylinder

Adjustment

Troubleshooting

Service Data

CHAPTER 5: BRAKE SYSTEM

Specifications

Structure

Master Cylinder

Wheel Cylinder

Wheel Brake

Parking Brake Lever

Adjustment and Tests

Troubleshooting

Service Data

CHAPTER 6: STEERING SYSTEM

Description

Steering Gear

Inspection after Removal

Disassembly

Reassembly

Suggestions

Steer Pump

CHAPTER 7: HYDRAULIC SYSTEM

Hydraulic System

Description

Schematic

Hydraulic Tank

Hydraulic Pump

Control Valve

Lift and Tilt Cylinders

Flow Regulator Valve

Down Safety Valve

Removal and Installation Warning

Hydraulic Pump

Removal

Installation

Disassembly

Inspection after Disassembly

Reassembly

Placing Pump Back into Service

Inspection after Reassembly

Trouble Shooting

Control Valve

Lift and Tilt Cylinders

Removal

Inspection after Disassembly

Precautions for Reassembly

Inspection and Adjustment

Hydraulic Tank

Control Valve

CHAPTER 8: MAST AND FORKS

Specifications

Description

Disassembly and Reassembly

Dual-stage Panoramic Mast (Simplex Mast)

Triple-stage Full Free Panoramic Mast (Triplex Mast)

Inspection and Adjustment

Mast Strip Adjustment

Troubleshooting

Service Data

CHAPTER 9: SERVICE DATA

Tightening Torques for Standard Bolts and Nuts

Maintenance Chart

Periodic Replacement Parts

Lubrication Chart

Fuel and Lubricant Specifications

Weight of Major Components

Special Service Tools

Special Tool Illustrations

Inspection Guide

4. Operate and Maintenance manual (OMM-WEBU8472-02)

Format: PDF, 124 pages

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC35N (A2BC4-60200-up)

FBC40N (A2BC4-60200-up)

FBC45N (A2BC4-60200-up)

FBC55N (A2BC5-60200-up)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Operate and Maintenance manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: GE SX Controls (SM-WENB8473-02-Controls)

Format: PDF, 143 pages

Language: English

3. Service Manual: Chassis & Mast (SM-WENB8472-01_07)

Format: PDF, 238 pages

Language: English

Table of Contents:

CHAPTER 1: GENERAL INFORMATION

Scope

Truck Models Covered

Nameplate and Serial Number Locations

Dimensions

Dimensions Chart

General Information (Standard Models)

CHAPTER 2: FRONT AXLE AND REDUCTION DIFFERENTIAL

Specifications

Structure

Procedures and Key Points for Removal and Installation

Axle Shaft and Hub

Troubleshooting

Service Data

CHAPTER 3: TRANSFER ASSEMBLY

Structure and Functions

Disassembly and Reassembly

Tightening Torque

CHAPTER 4: REAR AXLE

Specifications

Structure

Procedures and Key Points for Removal and Installation

Rear Axle Assembly

Steering Cylinder

Adjustment

Troubleshooting

Service Data

CHAPTER 5: BRAKE SYSTEM

Specifications

Structure

Master Cylinder

Wheel Cylinder

Wheel Brake

Parking Brake Lever

Adjustment and Tests

Troubleshooting

Service Data

CHAPTER 6: STEERING SYSTEM

Description

Steering Gear

Inspection after Removal

Disassembly

Reassembly

Suggestions

Steer Pump

CHAPTER 7: HYDRAULIC SYSTEM

Hydraulic System

Description

Schematic

Hydraulic Tank

Hydraulic Pump

Control Valve

Lift and Tilt Cylinders

Flow Regulator Valve

Down Safety Valve

Removal and Installation Warning

Hydraulic Pump

Removal

Installation

Disassembly

Inspection after Disassembly

Reassembly

Placing Pump Back into Service

Inspection after Reassembly

Trouble Shooting

Control Valve

Lift and Tilt Cylinders

Removal

Inspection after Disassembly

Precautions for Reassembly

Inspection and Adjustment

Hydraulic Tank

Control Valve

CHAPTER 8: MAST AND FORKS

Specifications

Description

Disassembly and Reassembly

Dual-stage Panoramic Mast (Simplex Mast)

Triple-stage Full Free Panoramic Mast (Triplex Mast)

Inspection and Adjustment

Mast Strip Adjustment

Troubleshooting

Service Data

CHAPTER 9: SERVICE DATA

Tightening Torques for Standard Bolts and Nuts

Maintenance Chart

Periodic Replacement Parts

Lubrication Chart

Fuel and Lubricant Specifications

Weight of Major Components

Special Service Tools

Special Tool Illustrations

Inspection Guide

4. Operate and Maintenance manual (OMM-WEBU8472-02)

Format: PDF, 124 pages

Language: English

Included

Fault Codes List

1Service Manual

2Operate and Maintenance manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары