Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FBC15K (A3BC1-10200-up), FBC18K (A3BC1-10200-up), FBC18KL (A3BC1-10200-up), FBC20K (A3BC2-10200-up), FBC25K (A3BC2-10200-up), FBC25KE (A3BC3-10200-up), FBC25KL (A3BC3-10200-up), FBC30K (A3BC3-10200-up) and FBC30KL (A3BC4-40200-up).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC15K (A3BC1-10200-up)

FBC18K (A3BC1-10200-up)

FBC18KL (A3BC1-10200-up)

FBC20K (A3BC2-10200-up)

FBC25K (A3BC2-10200-up)

FBC25KE (A3BC3-10200-up)

FBC25KL (A3BC3-10200-up)

FBC30K (A3BC3-10200-up)

FBC30KL (A3BC4-40200-up)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Operate and Maintenance manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: GE SX Controls (SM-99759-74120_04)

Format: PDF, 154 pages

Language: English

Table of Contents:

GENERAL INFORMATION & FEATURES

Glossary

Motor Options

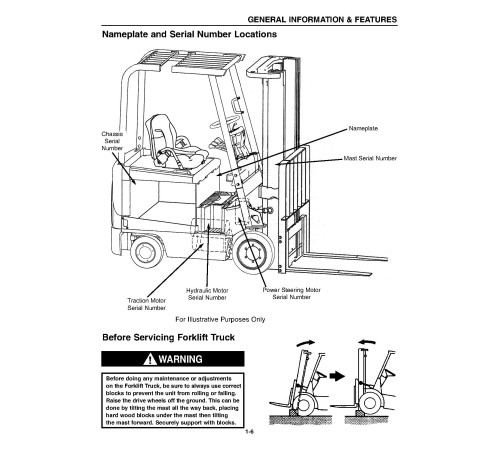

Nameplate and Serial Number Locations

Features of the Control System

Basics of Circuit Operation

Standard Display

Premium Display

Premium Display Set up Modes

Vehicle Monitoring System

Traction Control Logic Flow Chart

General Maintenance Instructions

General Trouble Shooting Instructions

PROGRAMMING

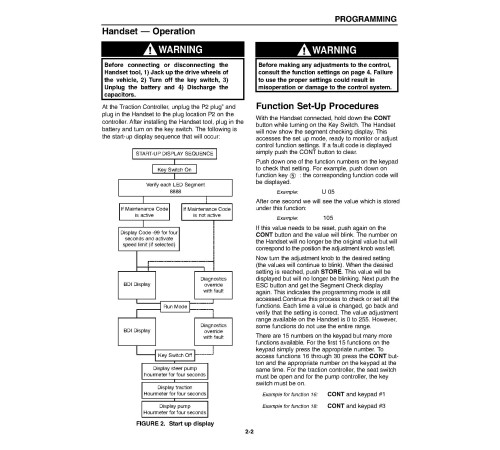

Handset

Operation

GE Sentry Set-up Procedures

Set-up Procedures

Function Settings

Controller Setup

Traction Controller Settings

Accelerator Setup

Pump Controller Settings

Memory Maps

Speedometer Setup

CHECKS & REPAIRS

General Information

Fuses

Exploded View of Contactor

Contactor Repair

Truck Management Module

Thermal Transfer

Traction Control

Trouble Shooting Tips (Motors)

Unsatisfactory Brush Performance

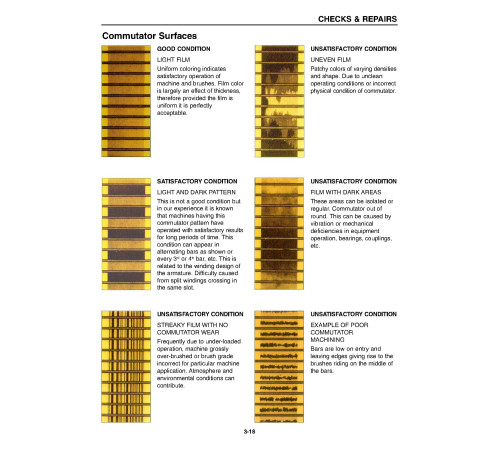

Commutator Surfaces Conditions

SX CONTROL CONNECTIONS & TROUBLESHOOTING BY SYMPTOM

SX Control

Failures that Cause Reduced or No Motor Torque

Misoperation of Other Features

WIRING

Traction Bypass with Pump Contactor Schematic

Pump Contactor Schematic

Traction Bypass with Pump Contactor Schematic

Traction Bypass with Pump Control Schematic

Pump Control Schematic

Traction Motor Controller with Pump motor Controller and Bypass

Voltage Checks

TMM7A (Truck Management Module)

Pump Driver

Pump Time Delay

DIAGNOSTIC STATUS CODES

Basic Checks

Status Codes .

3. Service Manual: Chassis & Mast (SM-99759-73110_04)

Format: PDF, 234 pages

Language: English

Table of Contents:

General Information

Scope

Truck Models Covered

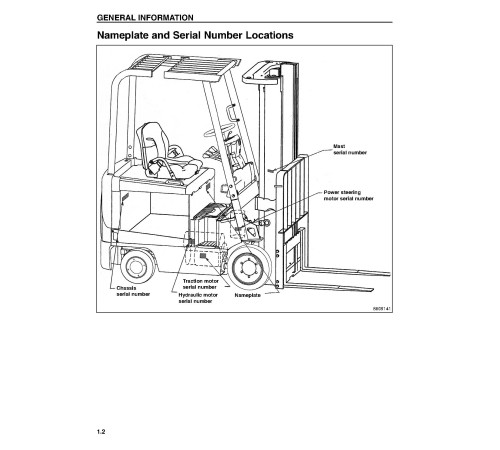

Nameplate and Serial Number Locations

Dimensions

Dimensions Chart

General Information (Standard Models)

Front Axle & Reduction Differential

Front Axle

Description

General Information

Front Wheels

Removal

Installation

Disassembly

Removing Front Wheel Hub

Inspection after Disassembly

Reassembly

Axle Housing

Front Wheel Hub

Hub Bearing Preload

Installation and Setting Preload

Reduction Differential

Description

Disassembly

Inspection after Disassembly

Reduction Gear

Differential

Reassembly

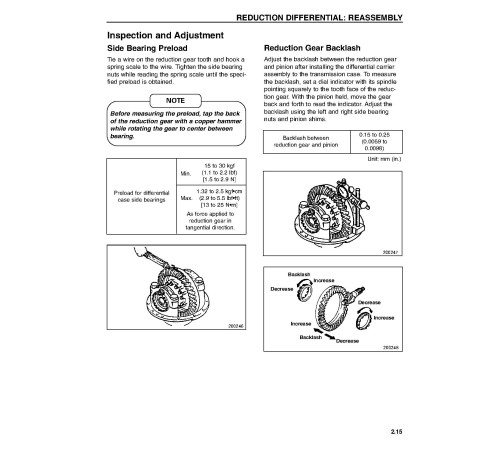

Inspection and Adjustment

Side Bearing Preload

Reduction Gear Backlash

Reduction Gear Face Runout

Tooth Contact

Tooth Contact Adjustment

Transfer Assembly

Description

Disassembly

Disassembly Sequence

Inspection after Disassembly

Reassembly

Rear Axle

Description

Rear Wheels

Removal

Installation

Rear Axle

Removal

Installation

Disassembly

Inspection after Disassembly

Reassembly

Inspection and Adjustment

Minimum Turning Radius Adjustment

Brake System

Description

Automatic Adjusting Device

General Information

Master Cylinder

Disassembly

Inspection after Disassembly

Reassembly

Service Brakes

Disassembly

(FBC15K - 18KL)

(FBC20K - 30KL)

Inspection after Disassembly

Reassembly

(FBC15K - 18KL)

(FBC20K - 30KL)

Wheel Cylinders

Disassembly

Inspection after Disassembly

Reassembly

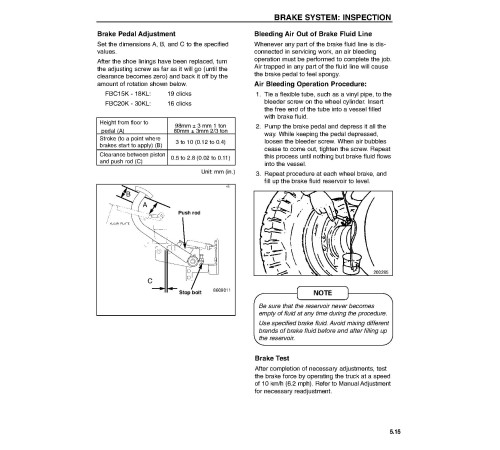

Inspection and Adjustment

Steering System

Steering System

Description

Steering System

Oil Flow Sequence

General Information

Steering Gear

Steering Wheel

Removal

Installation

Steering Gear

Inspection after Removal

Disassembly

Working Rules and Tips

Suggestions

Inspection after Disassembly

Reassembly

Suggestions

Steer Pump

Removal

Installation

Disassembly

Sequence

Working Rules and Tips

Suggestions

Inspection after Disassembly

Reassembly

Sequence

Suggestions

Inspection after Reassembly

Hydraulic System

Hydraulic System

Description

Schematic

Hydraulic Tank

Hydraulic Pump

Control Valve

Lift and Tilt Cylinders

Flow Regulator Valve

Down Safety Valve

Removal and Installation Warning

Hydraulic Pump

Removal

Installation

Disassembly

Working Rules and Tips

Suggestions

Inspection after Disassembly

Body

Mounting Flange Face

Bushes and Balance Plate

Gears

Reassembly

Inspection after Reassembly

Control Valve

Removal

Installation

Disassembly

Suggestions

Reassembly

Lift and Tilt Cylinders

Removal

Lift Cylinders

Tilt Cylinders

Disassembly

Lift Cylinders

Tilt Cylinders

Flow Regulator Valve

Inspection after Disassembly

Precautions for Reassembly

Inspection and Adjustment

Hydraulic Tank

Control Valve

Lift and Tilt Cylinders

Adjusting Method

Testing

Mast and Forks

Description

Removal and Installation

Disassembly

Inspection after Disassembly

Reassembly

Inspection and Adjustment

Forks

Chain Tension Adjustment

Clearance Adjustment on Lift Bracket

Mast Clearance Adjustment

Main Roller Shim Replacement

Mast Strip Adjustment

Tilt Angle Adjustment

Lift Cylinder Stroke Adjustment

Bleeding Lift Cylinders

Service Data

Troubleshooting

Troubleshooting Section

Front Axle and Reduction Differential

Brake System

Steering System

Hydraulic System

Rear Axle

Mast and Forks

Maintenance Service Data

Maintenance Service Data

Front Axle and Reduction Differential

Transfer Case

Rear Axle

Brake System

Steering System,

Hydraulic System

Mast and Forks (Simplex Mast)

Tightening Torques for Standard Bolts and Nuts

Fine Thread°With Spring Washer

Fine Thread°Without Spring Washer

Coarse Thread°With Spring Washer

Coarse Thread°With Spring Washer

Maintenance Chart

Planned Replacement Parts

Lubrication Information

Chart

Lubricant Specifications

Recommended Brands of Lubrications

Weight of Major Components (Approximate)

Special Service Tools

Special Tool Illustrations

Inspection Guide.

4. Operate and Maintenance manual (OMM-99750-73120)

Format: PDF, 122 pages

Language: English

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC15K (A3BC1-10200-up)

FBC18K (A3BC1-10200-up)

FBC18KL (A3BC1-10200-up)

FBC20K (A3BC2-10200-up)

FBC25K (A3BC2-10200-up)

FBC25KE (A3BC3-10200-up)

FBC25KL (A3BC3-10200-up)

FBC30K (A3BC3-10200-up)

FBC30KL (A3BC4-40200-up)

The manual comprises 4 documents, including the Fault Codes List, two Service Manuals, and Operate and Maintenance manual

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: GE SX Controls (SM-99759-74120_04)

Format: PDF, 154 pages

Language: English

Table of Contents:

GENERAL INFORMATION & FEATURES

Glossary

Motor Options

Nameplate and Serial Number Locations

Features of the Control System

Basics of Circuit Operation

Standard Display

Premium Display

Premium Display Set up Modes

Vehicle Monitoring System

Traction Control Logic Flow Chart

General Maintenance Instructions

General Trouble Shooting Instructions

PROGRAMMING

Handset

Operation

GE Sentry Set-up Procedures

Set-up Procedures

Function Settings

Controller Setup

Traction Controller Settings

Accelerator Setup

Pump Controller Settings

Memory Maps

Speedometer Setup

CHECKS & REPAIRS

General Information

Fuses

Exploded View of Contactor

Contactor Repair

Truck Management Module

Thermal Transfer

Traction Control

Trouble Shooting Tips (Motors)

Unsatisfactory Brush Performance

Commutator Surfaces Conditions

SX CONTROL CONNECTIONS & TROUBLESHOOTING BY SYMPTOM

SX Control

Failures that Cause Reduced or No Motor Torque

Misoperation of Other Features

WIRING

Traction Bypass with Pump Contactor Schematic

Pump Contactor Schematic

Traction Bypass with Pump Contactor Schematic

Traction Bypass with Pump Control Schematic

Pump Control Schematic

Traction Motor Controller with Pump motor Controller and Bypass

Voltage Checks

TMM7A (Truck Management Module)

Pump Driver

Pump Time Delay

DIAGNOSTIC STATUS CODES

Basic Checks

Status Codes .

3. Service Manual: Chassis & Mast (SM-99759-73110_04)

Format: PDF, 234 pages

Language: English

Table of Contents:

General Information

Scope

Truck Models Covered

Nameplate and Serial Number Locations

Dimensions

Dimensions Chart

General Information (Standard Models)

Front Axle & Reduction Differential

Front Axle

Description

General Information

Front Wheels

Removal

Installation

Disassembly

Removing Front Wheel Hub

Inspection after Disassembly

Reassembly

Axle Housing

Front Wheel Hub

Hub Bearing Preload

Installation and Setting Preload

Reduction Differential

Description

Disassembly

Inspection after Disassembly

Reduction Gear

Differential

Reassembly

Inspection and Adjustment

Side Bearing Preload

Reduction Gear Backlash

Reduction Gear Face Runout

Tooth Contact

Tooth Contact Adjustment

Transfer Assembly

Description

Disassembly

Disassembly Sequence

Inspection after Disassembly

Reassembly

Rear Axle

Description

Rear Wheels

Removal

Installation

Rear Axle

Removal

Installation

Disassembly

Inspection after Disassembly

Reassembly

Inspection and Adjustment

Minimum Turning Radius Adjustment

Brake System

Description

Automatic Adjusting Device

General Information

Master Cylinder

Disassembly

Inspection after Disassembly

Reassembly

Service Brakes

Disassembly

(FBC15K - 18KL)

(FBC20K - 30KL)

Inspection after Disassembly

Reassembly

(FBC15K - 18KL)

(FBC20K - 30KL)

Wheel Cylinders

Disassembly

Inspection after Disassembly

Reassembly

Inspection and Adjustment

Steering System

Steering System

Description

Steering System

Oil Flow Sequence

General Information

Steering Gear

Steering Wheel

Removal

Installation

Steering Gear

Inspection after Removal

Disassembly

Working Rules and Tips

Suggestions

Inspection after Disassembly

Reassembly

Suggestions

Steer Pump

Removal

Installation

Disassembly

Sequence

Working Rules and Tips

Suggestions

Inspection after Disassembly

Reassembly

Sequence

Suggestions

Inspection after Reassembly

Hydraulic System

Hydraulic System

Description

Schematic

Hydraulic Tank

Hydraulic Pump

Control Valve

Lift and Tilt Cylinders

Flow Regulator Valve

Down Safety Valve

Removal and Installation Warning

Hydraulic Pump

Removal

Installation

Disassembly

Working Rules and Tips

Suggestions

Inspection after Disassembly

Body

Mounting Flange Face

Bushes and Balance Plate

Gears

Reassembly

Inspection after Reassembly

Control Valve

Removal

Installation

Disassembly

Suggestions

Reassembly

Lift and Tilt Cylinders

Removal

Lift Cylinders

Tilt Cylinders

Disassembly

Lift Cylinders

Tilt Cylinders

Flow Regulator Valve

Inspection after Disassembly

Precautions for Reassembly

Inspection and Adjustment

Hydraulic Tank

Control Valve

Lift and Tilt Cylinders

Adjusting Method

Testing

Mast and Forks

Description

Removal and Installation

Disassembly

Inspection after Disassembly

Reassembly

Inspection and Adjustment

Forks

Chain Tension Adjustment

Clearance Adjustment on Lift Bracket

Mast Clearance Adjustment

Main Roller Shim Replacement

Mast Strip Adjustment

Tilt Angle Adjustment

Lift Cylinder Stroke Adjustment

Bleeding Lift Cylinders

Service Data

Troubleshooting

Troubleshooting Section

Front Axle and Reduction Differential

Brake System

Steering System

Hydraulic System

Rear Axle

Mast and Forks

Maintenance Service Data

Maintenance Service Data

Front Axle and Reduction Differential

Transfer Case

Rear Axle

Brake System

Steering System,

Hydraulic System

Mast and Forks (Simplex Mast)

Tightening Torques for Standard Bolts and Nuts

Fine Thread°With Spring Washer

Fine Thread°Without Spring Washer

Coarse Thread°With Spring Washer

Coarse Thread°With Spring Washer

Maintenance Chart

Planned Replacement Parts

Lubrication Information

Chart

Lubricant Specifications

Recommended Brands of Lubrications

Weight of Major Components (Approximate)

Special Service Tools

Special Tool Illustrations

Inspection Guide.

4. Operate and Maintenance manual (OMM-99750-73120)

Format: PDF, 122 pages

Language: English

Included

Fault Codes List

1Service Manual

2Operate and Maintenance manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары