$20.00

Fault Codes List

2Service Manual

4Operate and Maintenance manual

1Wiring Diagram

3Hydraulic Circuit Diagram

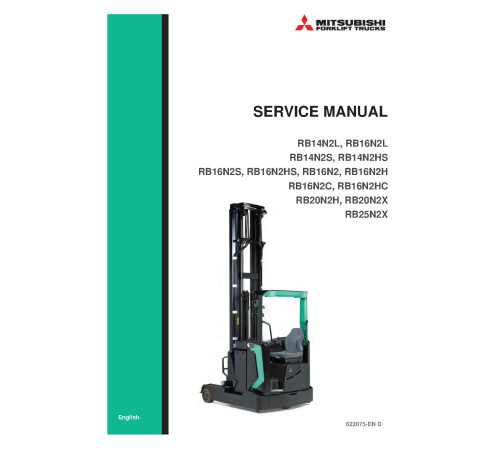

1Illustrated factory set of Service Manuals for Mitsubishi Reach Trucks Models RB14N2L, RB16N2L, RB14N2S, RB14N2HS, RB16N2S, RB16N2HS, RB16N2, RB16N2H, RB16N2C, RB16N2HC, RB20N2H, RB20N2X and RB25N2X.

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RB14N2L

RB16N2L

RB14N2S

RB14N2HS

RB16N2S

RB16N2HS

RB16N2

RB16N2H

RB16N2C

RB16N2HC

RB20N2H

RB20N2X

RB25N2X

The manual comprises 11 documents, including two Fault Codes Lists, four Service Manuals, the Operate and Maintenance manual, three Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List: Warnings (RB14N-RB25NH_Warnings)

Format: PDF, 3 pages

Language: English

2. Fault Codes List: Errors (RB14N-RB25NH_Errors)

Format: PDF, 9 pages

Language: English

3. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

4. Service Manual: ZAPI ACE2 Inverter (Zapi_Ace-2_Inverter)

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications ACE2

Technical specifications ACE2 Power

Block diagram

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Microswitches

Accelerator unit

Other analog control unit

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic - Traction configuration

Connectors of the logic - Pump configuration

Description of power connections

DRAWING

Mechanical drawing ACE2

Mechanical drawing ACE2 Power

Connection drawing - Traction configuration

Connection drawing - Pump configuration

Connection drawing - Combi configuration

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via Console

Description of Console & Connection

Description of Standard Console Menu

Function configuration

Parameter regulation

Programming console functions

Sequence for Ac Inverter Traction setting

Sequence for Ac Inverter Pump setting

Tester: description of the function

Description of the Console “SAVE” function

Description of Console “RESTORE” function

Description of Console “PROGRAM VACC” function

Description of the battery charge detection setting

Description of “ALARMS” menu

Faults diagnostic system

Microcontroller alarms overview

Analysis and troubleshooting of alarms displayed on console

Microcontroller warning overview

Analysis and troubleshooting of warnings displayed on console

RECOMMENDED SPARE PARTS FOR INVERTER

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

5. Service Manual (SM-622075-EN-14)

Format: PDF, 432 pages

Language: English

Publication Date: 04 Nov 2014

Table of Contents:

Foreword

How to read this manual

Safety-related signs

Symbols and abbreviations

Safety symbols.

Other symbols and abbreviations

Units

Safety instructions

Service area safety

Personal safety

Work safety

General information .

Truck model covered by this manual

Identification plates on the truck

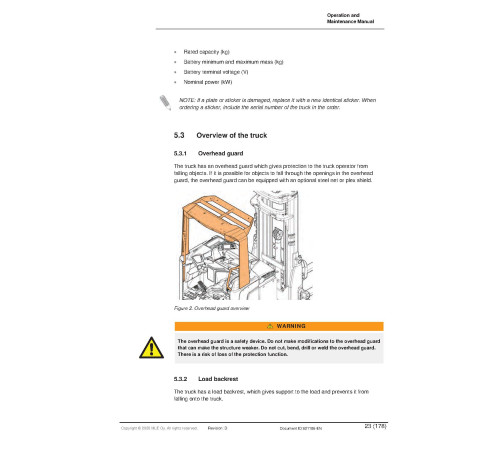

Overview of the truck

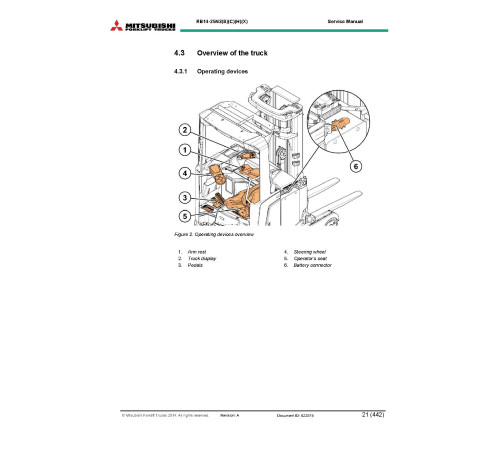

Operating devices

Control panel.

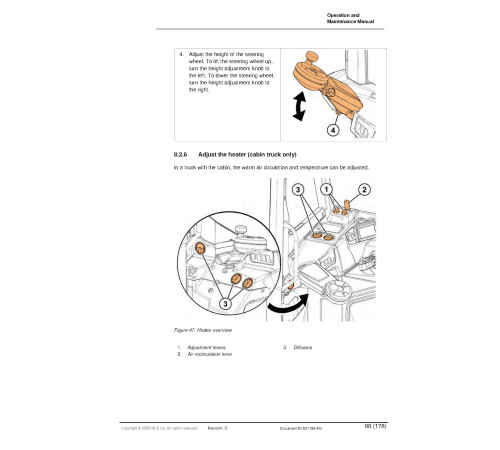

Steering wheel

Arm rest

Display panel

Truck operation modes.

Truck display

Display control buttons

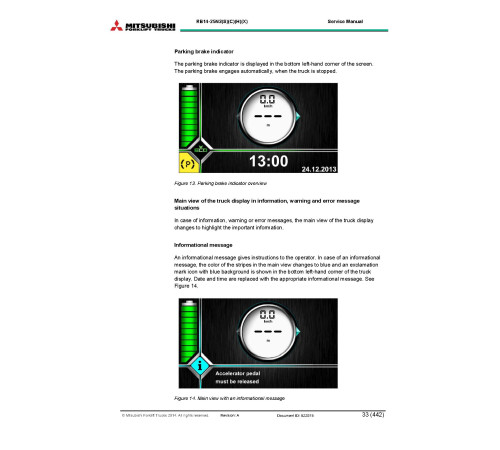

Main view of the truck display.

Hierarchy of the truck display menus.

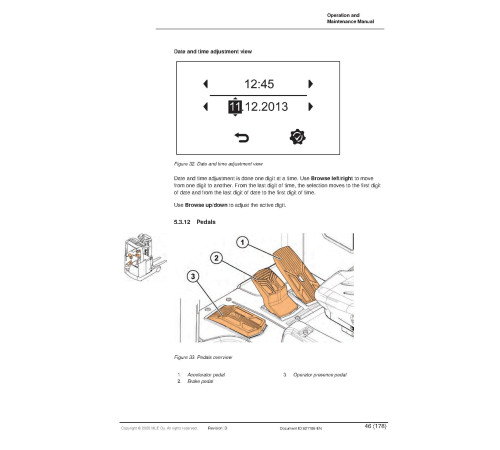

Pedals.

Operator°s seat

Operating position

Driving direction

Motor, hydraulic system and electrical system.

Instrument panel

Hydraulic system.

Motor compartment

Sensors.

Reach carriage.

Mast unit

Load support

Mechanical maintenance

Lifting points

Jack points

Hoist points

Transportation

Assembly and commissioning

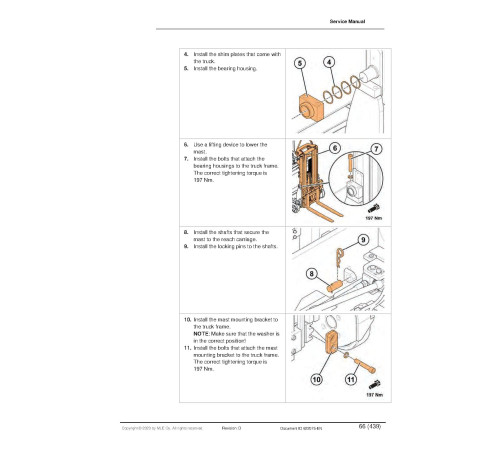

Install the mast unit

Order spare parts

Truck covers

Remove the machinery cover

Remove the front bumper.

Remove the floor plate

Open the machinery top cover

Open the instrument panel

Remove the instrument panel cover

Remove the control panel

Remove the cup holder

Remove the reach carriage cover.

Steering wheel

Remove the steering wheel

Transmission gear

Remove the transmission gear

Slewing bearing

Lubricate the slewing bearing

Traction wheel

Disassemble the traction wheel

Replace the wheel shaft bolts.

Assemble the traction wheel.

Corner supports

Replace the corner supports

Load wheels

Remove the load wheels

Battery roller frame

Remove the battery roller frame

Reach carriage

Lubricate the rollers of the reach carriage

Adjust the guidance rollers of the reach carriage

Sensors of the reach carriage

Remove the reach carriage

Remove the reach cylinder.

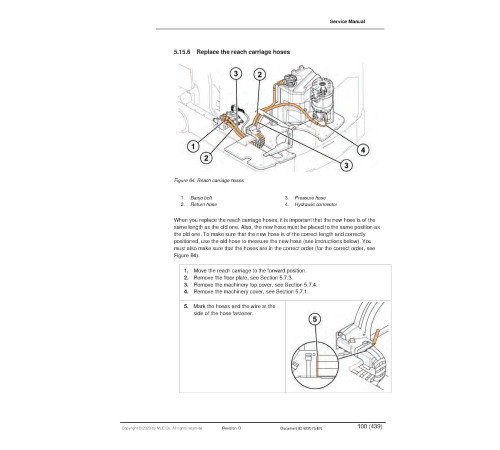

Replace the reach carriage hoses

Mast unit

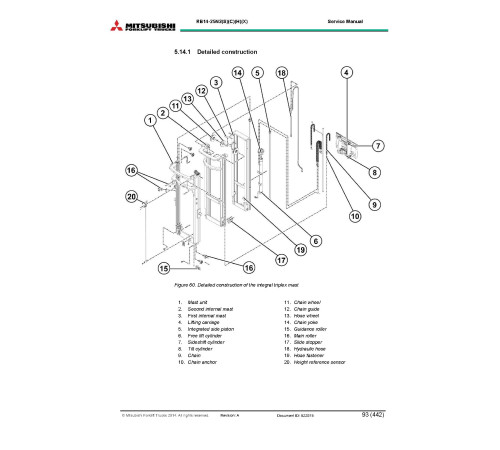

Detailed construction.

Mast unit maintenance

Daily maintenance.

Monthly maintenance

Annual maintenance (600 h)

Lubricant recommendations

Mast chains.

Mast channels.

Remove the lifting carriage.

Remove the mast unit

Disassemble the mast unit

Fork inspection.

Mast chains.

Inspect the mast chains.

Check the tension of the mast chains

Adjust the mast chains

Replace the mast chains

Guidance rollers

Adjust the guidance rollers

Replace the guidance rollers

Main rollers

Replace the main rollers.

Free lift cylinder.

Replace the free lift cylinder

Sealing housing of the free lift cylinder

Bleed out the air from the free lift cylinder

Side cylinders.

Replace the side cylinders

Sealing housing of the side cylinder

Bleed out the air from the side cylinders

Tilt cylinders

Remove the tilt cylinders

Sealing housing of the tilt cylinder

Sideshift cylinder

Remove the piston of the sideshift cylinder

Sealing housing of the sideshift cylinder

Load support

Remove the load support

Arm rest

Remove the arm rest.

Open the arm rest

Remove the arm rest levers

Remove the arm rest buttons

Operator°s seat

Replace the seat switch

Electrical operation

How to use the schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

Battery maintenance

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

Daily maintenance.

Weekly maintenance.

Monthly maintenance

Annual maintenance

Recharge the battery

Measure the specific gravity of the battery

Replace the battery

Guide the battery connector cables

Quick battery replacement

Electric system maintenance

Display panel

Emergency stop button

Emergency stop button functionality check

Key switch.

Key switch functionality check

Pedals

Operator presence pedal.

Operator presence pedal functionality check

Remove the operator presence pedal

Acceleration pedal.

Acceleration pedal functionality check

Remove the acceleration pedal

Brake pedal.

Brake pedal functionality check

Remove the brake pedal

Instrument panel

Discharge the controllers.

Vehicle controller.

Vehicle controller connectors

CNA external connector

CNB external connector

Traction controller

Traction controller connectors

CNA external connector

Description of the power connections

Pump controller

Pump controller connectors.

CNA external connector

Description of the power connections

Steering controller

Steering controller connectors

CNA external connector

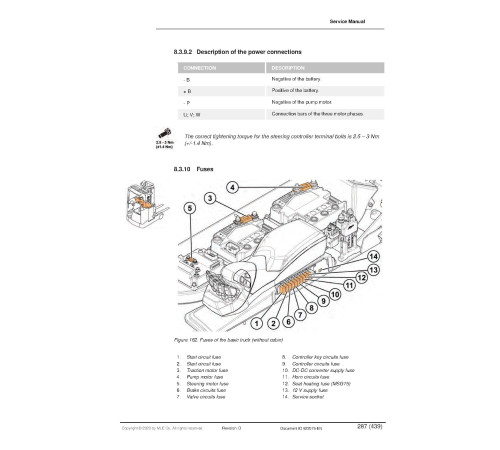

Description of the power connections

Fuses

Remove the gas spring of the instrument panel.

Motor compartment

Traction motor

Remove the traction motor

Temperature sensor check.

HALL sensor

Steering motor

Remove the steering motor

Temperature sensor check.

HALL sensor

Magnetic brake

Coil resistance measurement

Install the magnetic brake

Adjust the air gap of the magnetic brake

Release the magnetic brake manually.

Pump motor

Pump motor (Standard model)

Pump motor (High performance model).

Replace the HALL sensor

Sensors

Steering wheel sensor.

Steering wheel sensor functionality check

Steering control safety circuit check

Steering reference sensor

Steering reference sensor functionality check

Reach end stop, retract limit, retract end stop and reach limit switch

Reach end stop, retract limit, retract end stop and reach limit switch functionality check

Battery lock sensor.

Battery lock sensor functionality check

Pressure sensor

Pressure sensor functionality check

Height reference sensor

Height reference sensor functionality check

Electric system adjustments and measurements

Calibrate the arm rest levers

Insulation resistance test

Test voltage

Checking the insulation tester

Measure the insulation resistance

Insulation resistance of the truck

Insulation resistance of the battery

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Replace the hydraulic oil return filter (sieve)

Clean the hydraulic oil suction filter

Hydraulic system

Disassemble the hydraulic system

Hydraulic valve unit

Valve M1

Valve M3, M4, M7 and M8

Valve M2, M5, M6, M9 and M10.

Emergency lowering valve

Set the lifting pressure.

Disassemble the valves.

TruckTool Diagnostics

Parameter descriptions

VCM

Traction controller

Pump controller

EPS controller

Alarm codes

VCM

VCM master

VCM slave

Traction controller

Pump controller

EPS

EPS master.

EPS slave

Service data

Special tightening torques

Tightening torque for standard bolts and nuts

Maintenance check list

Lubrication

Hydraulic oil

Transmission oil

Special tools

Options

Special color labels

Customer design labels

Display languages

Accessory rack

Install the accessory rack

Install the list bracket

Install the computer rack

Install the rear view mirror

Accessory rack under the truck floor

Install the accessory rack under the floor

Reading lamp

Install the reading lamp

Audio system

Install the audio system

Warning light

Install the warning light

Working lights

Install the working lights

Operator compartment fan

Install the operator compartment fan

Drive alarm (programmable)

Install the drive alarm

Steel safety net for overhead guard

Install the steel safety net to the overhead guard.

Plexiglass safety cover for the overhead guard

Install the plexiglass safety cover to the overhead guard

Left shoulder protection plate

Install the left shoulder protection plate

Fire extinguisher

Install the fire extinguisher

Cold storage modification

Hot storage modification

Current output

Install the DC-DC converter.

Quick battery changing device for 2 batteries

Remove an empty battery with the battery changing device for 2 batteries

Install a recharged battery with the battery changing device for 2 batteries

Battery connector + cables

Replace the battery connector.

Charger connector

Replace the charger connector

Extra valve with hosing to fork carriage

Fork positioner with sideshift

Fork carriage strengthening part

Fork camera with 7° LCD color display

Telescopic forks

Sideshift and tilt centering

Sideshift centering direction, sideshift centering midpoint and tilt centering sensor

Sideshift centering direction, sideshift centering midpoint and tilt centering sensor functionality check

Load weight indicator

Electric load wheel brakes

Lowering cut-off

Operator°s seat options and accessories

Arm rest

Backrest extension for MSG65/MSG75

Backrest extension adjustment.

Seat belt for MSG20 seat

Install the seat belt

PIN code access to the Start switch

Lifting height pre-selection

How to unstack with the lifting height pre-selection

How to stack with the lifting height pre-selection

Technical specification

RB14N2S, RB14N2HS, RB16N2S, RB16N2HS and RB16N2

RB16N2H, RB16N2C, RB16N2HC, RB20N2H, RB20N2X and RB25N2X

Mast heights

Index

APPENDIX A: Stickers.

6. Service Manual (SM-622075-EN_20)

Format: PDF, 439 pages

Language: English

Publication Date: 09 Nov 2020

7. Operate and Maintenance manual (OMM-621186-EN_21)

Format: PDF, 178 pages

Language: English

8. Wiring Diagram: Cold Cabin (EL-TS1380000_RevD_Cold_cabin)

Format: PDF, 18 pages

Language: English

Table of Contents:

SUPPLY

MOTOR CIRCUITS

MAIN CIRCUITS

DRIVE CIRCUIT

STEERING CIRCUIT

HYDRAULIC CONTROL CIRCUITS

HYDRAULIC VALVES

MAST AND REACH CARRIAGE SENSORS

FORK CARRIAGE

CAN-BUS

FANS AND AUX DEVICES

AUX DEVICES 2

AUX. DEVICES III

AUX DEVICES IV

COLD CABIN

COLD CABIN II

CABIN CONNECTOR LAYOUT

9. Wiring Diagram (EL-E001060-B)

Format: PDF, 17 pages

Language: English

Table of Contents:

SISLLYS

JNNITESYTT

MOOTTORIKYTKENNT

PPIIRIT

AJOPIIRIT

OHJAUSPIIRIT

HYDRAULIIKAN OHJAUSPIIRIT

HYDRAULIVENTTIILIT

MASTON JA TYNTKELKAN ANTURIT

HAARUKKAKELKKA

CAN-VYL

TUULETTIMET JA LISLAITTEET

LISLAITTEET 2

LISLAITTEET III

LISLAITTEET IV

LISLAITTEET V

OPTIO KAKSOISKAASUPOLJIN

10. Wiring Diagram (EL-DOC00024389-H)

Format: PDF, 17 pages

Language: English

Table of Contents:

SUPPLY

MOTOR CIRCUITS

MAIN CIRCUITS

DRIVE CIRCUIT

STEERING CIRCUIT

HYDRAULIC CONTROL CIRCUITS

HYDRAULIC VALVES

MAST AND REACH CARRIAGE SENSORS

FORK CARRIAGE

CAN-BUS

FANS AND AUX DEVICES

AUX DEVICES 2

AUX. DEVICES III

AUX DEVICES IV

AUX DEVICES V

OPTION DUAL PEDAL

11. Hydraulic Circuit Diagram (EL-TS1380000_RevA)

Format: PDF, 1 page

Language: English

Table of Contents:

Main Hydraulic Circuit

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, operating, maintaining, and troubleshooting for your reach truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

RB14N2L

RB16N2L

RB14N2S

RB14N2HS

RB16N2S

RB16N2HS

RB16N2

RB16N2H

RB16N2C

RB16N2HC

RB20N2H

RB20N2X

RB25N2X

The manual comprises 11 documents, including two Fault Codes Lists, four Service Manuals, the Operate and Maintenance manual, three Wiring Diagrams, and Hydraulic Circuit Diagram

1. Fault Codes List: Warnings (RB14N-RB25NH_Warnings)

Format: PDF, 3 pages

Language: English

2. Fault Codes List: Errors (RB14N-RB25NH_Errors)

Format: PDF, 9 pages

Language: English

3. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

4. Service Manual: ZAPI ACE2 Inverter (Zapi_Ace-2_Inverter)

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications ACE2

Technical specifications ACE2 Power

Block diagram

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Microswitches

Accelerator unit

Other analog control unit

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic - Traction configuration

Connectors of the logic - Pump configuration

Description of power connections

DRAWING

Mechanical drawing ACE2

Mechanical drawing ACE2 Power

Connection drawing - Traction configuration

Connection drawing - Pump configuration

Connection drawing - Combi configuration

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via Console

Description of Console & Connection

Description of Standard Console Menu

Function configuration

Parameter regulation

Programming console functions

Sequence for Ac Inverter Traction setting

Sequence for Ac Inverter Pump setting

Tester: description of the function

Description of the Console “SAVE” function

Description of Console “RESTORE” function

Description of Console “PROGRAM VACC” function

Description of the battery charge detection setting

Description of “ALARMS” menu

Faults diagnostic system

Microcontroller alarms overview

Analysis and troubleshooting of alarms displayed on console

Microcontroller warning overview

Analysis and troubleshooting of warnings displayed on console

RECOMMENDED SPARE PARTS FOR INVERTER

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

5. Service Manual (SM-622075-EN-14)

Format: PDF, 432 pages

Language: English

Publication Date: 04 Nov 2014

Table of Contents:

Foreword

How to read this manual

Safety-related signs

Symbols and abbreviations

Safety symbols.

Other symbols and abbreviations

Units

Safety instructions

Service area safety

Personal safety

Work safety

General information .

Truck model covered by this manual

Identification plates on the truck

Overview of the truck

Operating devices

Control panel.

Steering wheel

Arm rest

Display panel

Truck operation modes.

Truck display

Display control buttons

Main view of the truck display.

Hierarchy of the truck display menus.

Pedals.

Operator°s seat

Operating position

Driving direction

Motor, hydraulic system and electrical system.

Instrument panel

Hydraulic system.

Motor compartment

Sensors.

Reach carriage.

Mast unit

Load support

Mechanical maintenance

Lifting points

Jack points

Hoist points

Transportation

Assembly and commissioning

Install the mast unit

Order spare parts

Truck covers

Remove the machinery cover

Remove the front bumper.

Remove the floor plate

Open the machinery top cover

Open the instrument panel

Remove the instrument panel cover

Remove the control panel

Remove the cup holder

Remove the reach carriage cover.

Steering wheel

Remove the steering wheel

Transmission gear

Remove the transmission gear

Slewing bearing

Lubricate the slewing bearing

Traction wheel

Disassemble the traction wheel

Replace the wheel shaft bolts.

Assemble the traction wheel.

Corner supports

Replace the corner supports

Load wheels

Remove the load wheels

Battery roller frame

Remove the battery roller frame

Reach carriage

Lubricate the rollers of the reach carriage

Adjust the guidance rollers of the reach carriage

Sensors of the reach carriage

Remove the reach carriage

Remove the reach cylinder.

Replace the reach carriage hoses

Mast unit

Detailed construction.

Mast unit maintenance

Daily maintenance.

Monthly maintenance

Annual maintenance (600 h)

Lubricant recommendations

Mast chains.

Mast channels.

Remove the lifting carriage.

Remove the mast unit

Disassemble the mast unit

Fork inspection.

Mast chains.

Inspect the mast chains.

Check the tension of the mast chains

Adjust the mast chains

Replace the mast chains

Guidance rollers

Adjust the guidance rollers

Replace the guidance rollers

Main rollers

Replace the main rollers.

Free lift cylinder.

Replace the free lift cylinder

Sealing housing of the free lift cylinder

Bleed out the air from the free lift cylinder

Side cylinders.

Replace the side cylinders

Sealing housing of the side cylinder

Bleed out the air from the side cylinders

Tilt cylinders

Remove the tilt cylinders

Sealing housing of the tilt cylinder

Sideshift cylinder

Remove the piston of the sideshift cylinder

Sealing housing of the sideshift cylinder

Load support

Remove the load support

Arm rest

Remove the arm rest.

Open the arm rest

Remove the arm rest levers

Remove the arm rest buttons

Operator°s seat

Replace the seat switch

Electrical operation

How to use the schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

Battery maintenance

Safety regulations concerning the handling of lead-acid batteries

Battery maintenance

Daily maintenance.

Weekly maintenance.

Monthly maintenance

Annual maintenance

Recharge the battery

Measure the specific gravity of the battery

Replace the battery

Guide the battery connector cables

Quick battery replacement

Electric system maintenance

Display panel

Emergency stop button

Emergency stop button functionality check

Key switch.

Key switch functionality check

Pedals

Operator presence pedal.

Operator presence pedal functionality check

Remove the operator presence pedal

Acceleration pedal.

Acceleration pedal functionality check

Remove the acceleration pedal

Brake pedal.

Brake pedal functionality check

Remove the brake pedal

Instrument panel

Discharge the controllers.

Vehicle controller.

Vehicle controller connectors

CNA external connector

CNB external connector

Traction controller

Traction controller connectors

CNA external connector

Description of the power connections

Pump controller

Pump controller connectors.

CNA external connector

Description of the power connections

Steering controller

Steering controller connectors

CNA external connector

Description of the power connections

Fuses

Remove the gas spring of the instrument panel.

Motor compartment

Traction motor

Remove the traction motor

Temperature sensor check.

HALL sensor

Steering motor

Remove the steering motor

Temperature sensor check.

HALL sensor

Magnetic brake

Coil resistance measurement

Install the magnetic brake

Adjust the air gap of the magnetic brake

Release the magnetic brake manually.

Pump motor

Pump motor (Standard model)

Pump motor (High performance model).

Replace the HALL sensor

Sensors

Steering wheel sensor.

Steering wheel sensor functionality check

Steering control safety circuit check

Steering reference sensor

Steering reference sensor functionality check

Reach end stop, retract limit, retract end stop and reach limit switch

Reach end stop, retract limit, retract end stop and reach limit switch functionality check

Battery lock sensor.

Battery lock sensor functionality check

Pressure sensor

Pressure sensor functionality check

Height reference sensor

Height reference sensor functionality check

Electric system adjustments and measurements

Calibrate the arm rest levers

Insulation resistance test

Test voltage

Checking the insulation tester

Measure the insulation resistance

Insulation resistance of the truck

Insulation resistance of the battery

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Replace the hydraulic oil return filter (sieve)

Clean the hydraulic oil suction filter

Hydraulic system

Disassemble the hydraulic system

Hydraulic valve unit

Valve M1

Valve M3, M4, M7 and M8

Valve M2, M5, M6, M9 and M10.

Emergency lowering valve

Set the lifting pressure.

Disassemble the valves.

TruckTool Diagnostics

Parameter descriptions

VCM

Traction controller

Pump controller

EPS controller

Alarm codes

VCM

VCM master

VCM slave

Traction controller

Pump controller

EPS

EPS master.

EPS slave

Service data

Special tightening torques

Tightening torque for standard bolts and nuts

Maintenance check list

Lubrication

Hydraulic oil

Transmission oil

Special tools

Options

Special color labels

Customer design labels

Display languages

Accessory rack

Install the accessory rack

Install the list bracket

Install the computer rack

Install the rear view mirror

Accessory rack under the truck floor

Install the accessory rack under the floor

Reading lamp

Install the reading lamp

Audio system

Install the audio system

Warning light

Install the warning light

Working lights

Install the working lights

Operator compartment fan

Install the operator compartment fan

Drive alarm (programmable)

Install the drive alarm

Steel safety net for overhead guard

Install the steel safety net to the overhead guard.

Plexiglass safety cover for the overhead guard

Install the plexiglass safety cover to the overhead guard

Left shoulder protection plate

Install the left shoulder protection plate

Fire extinguisher

Install the fire extinguisher

Cold storage modification

Hot storage modification

Current output

Install the DC-DC converter.

Quick battery changing device for 2 batteries

Remove an empty battery with the battery changing device for 2 batteries

Install a recharged battery with the battery changing device for 2 batteries

Battery connector + cables

Replace the battery connector.

Charger connector

Replace the charger connector

Extra valve with hosing to fork carriage

Fork positioner with sideshift

Fork carriage strengthening part

Fork camera with 7° LCD color display

Telescopic forks

Sideshift and tilt centering

Sideshift centering direction, sideshift centering midpoint and tilt centering sensor

Sideshift centering direction, sideshift centering midpoint and tilt centering sensor functionality check

Load weight indicator

Electric load wheel brakes

Lowering cut-off

Operator°s seat options and accessories

Arm rest

Backrest extension for MSG65/MSG75

Backrest extension adjustment.

Seat belt for MSG20 seat

Install the seat belt

PIN code access to the Start switch

Lifting height pre-selection

How to unstack with the lifting height pre-selection

How to stack with the lifting height pre-selection

Technical specification

RB14N2S, RB14N2HS, RB16N2S, RB16N2HS and RB16N2

RB16N2H, RB16N2C, RB16N2HC, RB20N2H, RB20N2X and RB25N2X

Mast heights

Index

APPENDIX A: Stickers.

6. Service Manual (SM-622075-EN_20)

Format: PDF, 439 pages

Language: English

Publication Date: 09 Nov 2020

7. Operate and Maintenance manual (OMM-621186-EN_21)

Format: PDF, 178 pages

Language: English

8. Wiring Diagram: Cold Cabin (EL-TS1380000_RevD_Cold_cabin)

Format: PDF, 18 pages

Language: English

Table of Contents:

SUPPLY

MOTOR CIRCUITS

MAIN CIRCUITS

DRIVE CIRCUIT

STEERING CIRCUIT

HYDRAULIC CONTROL CIRCUITS

HYDRAULIC VALVES

MAST AND REACH CARRIAGE SENSORS

FORK CARRIAGE

CAN-BUS

FANS AND AUX DEVICES

AUX DEVICES 2

AUX. DEVICES III

AUX DEVICES IV

COLD CABIN

COLD CABIN II

CABIN CONNECTOR LAYOUT

9. Wiring Diagram (EL-E001060-B)

Format: PDF, 17 pages

Language: English

Table of Contents:

SISLLYS

JNNITESYTT

MOOTTORIKYTKENNT

PPIIRIT

AJOPIIRIT

OHJAUSPIIRIT

HYDRAULIIKAN OHJAUSPIIRIT

HYDRAULIVENTTIILIT

MASTON JA TYNTKELKAN ANTURIT

HAARUKKAKELKKA

CAN-VYL

TUULETTIMET JA LISLAITTEET

LISLAITTEET 2

LISLAITTEET III

LISLAITTEET IV

LISLAITTEET V

OPTIO KAKSOISKAASUPOLJIN

10. Wiring Diagram (EL-DOC00024389-H)

Format: PDF, 17 pages

Language: English

Table of Contents:

SUPPLY

MOTOR CIRCUITS

MAIN CIRCUITS

DRIVE CIRCUIT

STEERING CIRCUIT

HYDRAULIC CONTROL CIRCUITS

HYDRAULIC VALVES

MAST AND REACH CARRIAGE SENSORS

FORK CARRIAGE

CAN-BUS

FANS AND AUX DEVICES

AUX DEVICES 2

AUX. DEVICES III

AUX DEVICES IV

AUX DEVICES V

OPTION DUAL PEDAL

11. Hydraulic Circuit Diagram (EL-TS1380000_RevA)

Format: PDF, 1 page

Language: English

Table of Contents:

Main Hydraulic Circuit

Included

Fault Codes List

2Service Manual

4Operate and Maintenance manual

1Wiring Diagram

3Hydraulic Circuit Diagram

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары