Illustrated factory set of Service Manuals for Mitsubishi Gasoline Forklift Trucks Models FG20S (CF54-10011-up), FG25S (CF54-50011-up) and FG30S (CF55-10011-up).

This manuals will assist you in diagnosing, analyses, testing, repair, repairing engine, operating, and maintaining for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FG20S (CF54-10011-up)

FG25S (CF54-50011-up)

FG30S (CF55-10011-up)

The manual comprises 6 documents, including two Service Manuals, two Engine Technical Manuals, and two Operate and Maintenance manuals

1. Service Manual: Asia (SM-99729-10120_1117A)

Format: PDF, 479 pages

Language: English

2. Service Manual: Asia, Europe, USA (SM-99729-10110_0318AEU)

Format: PDF, 479 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Applicable Truck Model

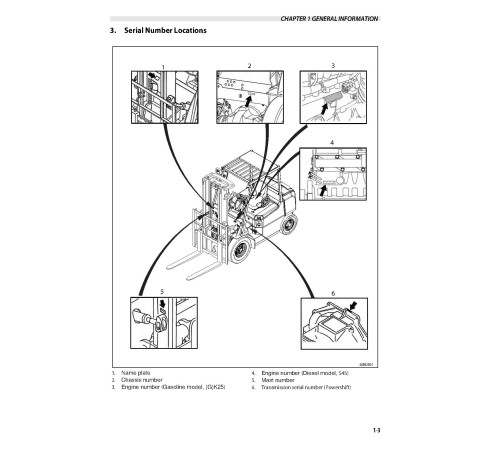

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Structure

Removing Fan Belt

Installing Fan Belt

Inspecting and Adjusting Cooling System

ELECTRICAL SYSTEM

Electrical Components and Wiring Outline

Console Box

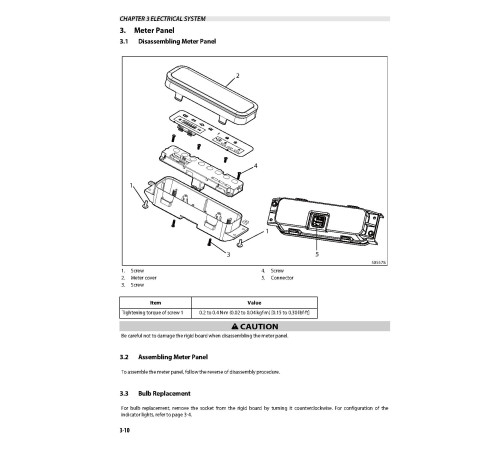

Meter Panel

Main Electrical Components

Battery and Maintenance

Wire Color

Troubleshooting

POWER TRAIN

Installation of Engine and Transmission Assembly (for Dual Gas/LPG Models)

Installation of Engine and Transmission Assembly (for Diesel Model)

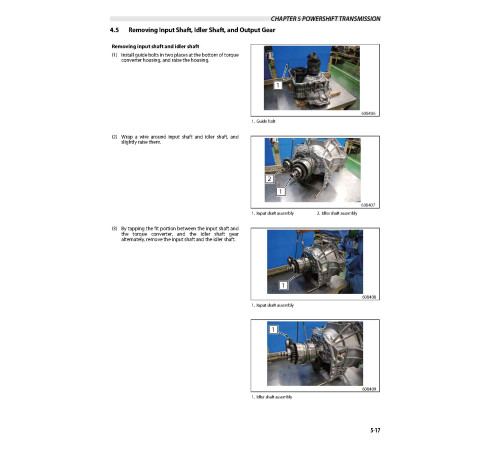

POWERSHIFT TRANSMISSION

Structure

Removing Transmission

Installing Transmission

Disassembling Torque ConverterTransmission

Assembling Torque Converter Transmission

Disassembling Control Valve

Assembling Control Valve

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removing Front Wheels

Installing Front Wheels

Removing Front Axle and Reduction Differential

Installing Front Axle

Disassembling Front Axle

Inspection and Repair After Disassembling Front Axle

Assembling Front Axle

Disassembling Reduction Differential

Inspection and Repair After Disassembling Reduction Differential

Assembling Reduction Differential

Troubleshooting

Service Data

REAR AXLE

Rear Axle Structure

Removing Rear Wheels

Installing Rear Wheels

Removing Rear Axle Assembly

Inspection and Repair After Disassembling Rear Axle Assembly

Installing Axle Assembly

Disassembling Wheel Hub

Inspection and Repair After Disassembling Wheel Hub Section

Assembling Wheel Hub Section

Disassembling Knuckle Section (Kingpin)

Inspection After Disassembly Knuckle Section (Kingpin)

Assembling Knuckle Section (Kingpin)

Removing Steering Cylinder

Disassembling Steering Cylinder

Inspection and Repair After Disassembling Steering Cylinder

Assembling Steering Cylinder

Disassembling Tie Rod

Assembling Tie Rod

BRAKE SYSTEM

Structure of Brake System

Disassembling Master Cylinder

Inspection and Repair After Disassembling Master Cylinder

Assembling Master Cylinder.

Structure of Wheel Brakes

Disassembling Wheel Brakes

Inspection and Repair After Disassembling Wheel Brakes

Assembling Wheel Brakes

Disassembling Wheel Cylinder

Inspection and Repair After Disassembling Wheel Cylinder

Assembling Wheel Cylinder.

Inspecting and Adjusting Brake System

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembling and Assembling Pipes and Hoses

Disassembling Steering Wheel and Steering Valve

Installing Steering Wheel and Steering Valve

Installation

Removing Steering Valve

Installing Steering Valve

Disassembling Tilt Lock Lever

Assembling Tilt Lock Lever

Disassembling Steering Valve

Inspection After Disassembly

Assembling Steering Valve

Troubleshooting

Service Data

HYDRAULIC SYSTEM

Structure and Functions

Removing Hydraulic Pump

Installing Hydraulic Pump

Disassembling Hydraulic Pump

Inspecting and Repairing Hydraulic Pump

Assembling Hydraulic Pump

Removing Lift Cylinders

Disassembling Lift Cylinder (First Cylinder for Duplex and Triplex Masts)

Inspecting Lift Cylinder (First Cylinder for Duplex and Triplex Masts)

Assembling Lift Cylinders (First Cylinder for Duplex and Triplex Masts)

Disassembling Lift Cylinder (Second Cylinder for Simplex Mast and Triplex Mast)

Inspecting Lift Cylinder (Second Cylinder for Simplex Mast and Triplex Mast)

Assembling Lift Cylinders (Second Cylinder for Simplex Mast and Triplex Mast)

Removing Tilt Cylinders

Installing Tilt Cylinders

Disassembling Tilt Cylinder

Inspection After Disassembling Tilt Cylinder

Assembling Tilt Cylinder

Piping

Removing Suction Strainer and Return Filter

Inspecting Suction Strainer and Return Filter

Installing Suction Strainer and Return Filter

Inspection and Adjustment

Troubleshooting

Service Data

Outline of Control Valve

Removing Control Valve

Installing Control Valve

Disassembling Control Valve - Inlet Section

Disassembling Control Valve - Lift Valve

Disassembling Control Valve - Tilt Valve

Disassembling Control Valve - End Cover Section

Disassembling Control Valve - End Cover Section

Assembling Control Valve - End Cover Section

Assembling AttachmentSection (Option)

MAST AND FORKS

Simplex Mast

Duplex Mast

Triplex Mast

SERVICE DATA

Maintenance Schedule

Tightening Torques for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Schedule

Special tools

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM FOR DUAL GAS/LPG ENGINE MODELS

CIRCUIT DIAGRAM FOR DIESEL ENGINE MODELS

3. Engine Technical Manual: GK15, GK21, GK25 Gasoline Engine (EN-99789-73100_GK15-GK21-GK25_1118AEU)

Format: PDF, 128 pages

Language: English

Table of Contents:

GENERAL INFORMATION

MAINTENANCE

ENGINE TUNE-UP

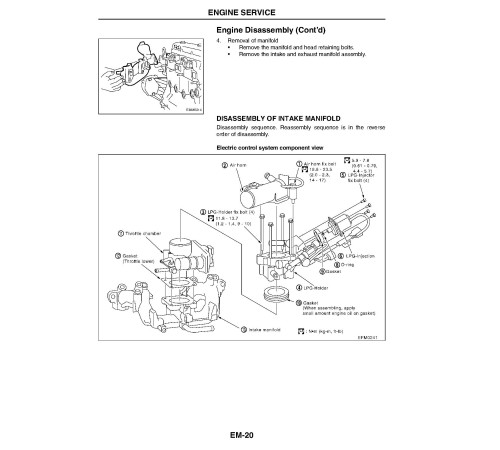

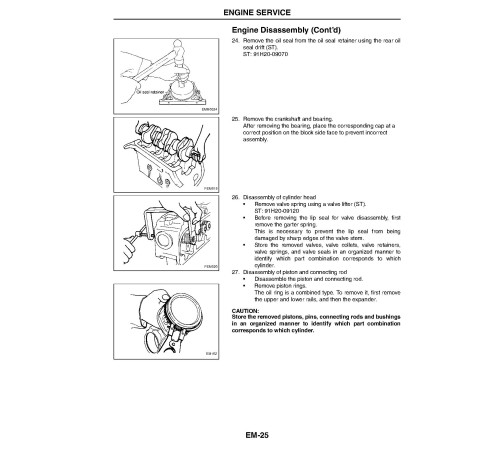

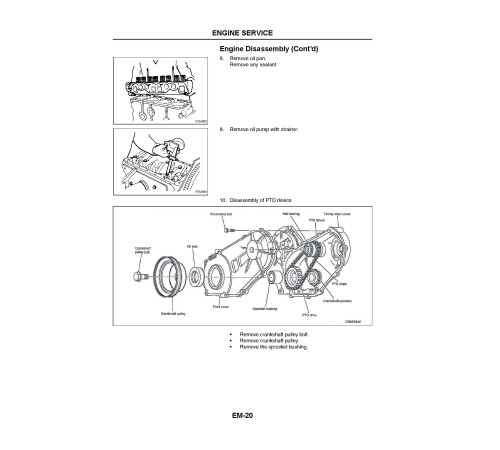

ENGINE MECHANICAL

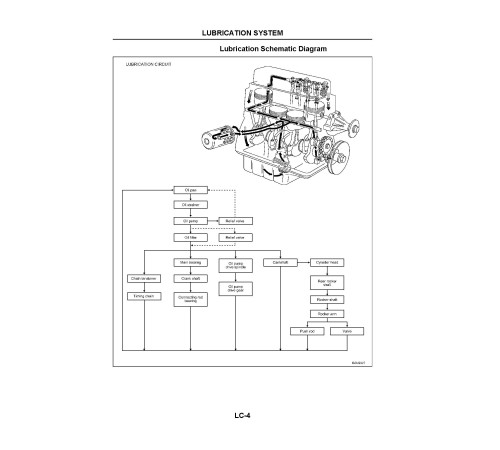

ENGINE LUBRICATION & COOLING SYSTEMS

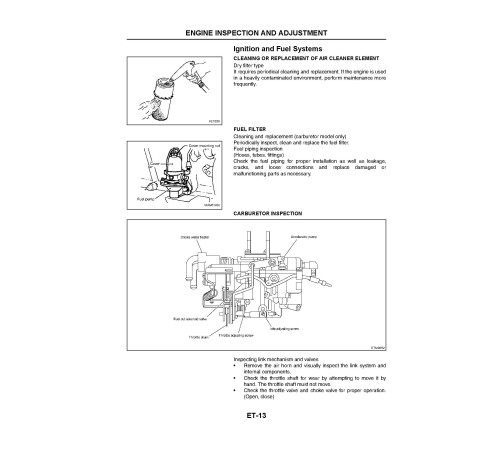

ENGINE FUEL

ENGINE ELECTRICAL

4. Engine Technical Manual: K15, K21, K25 Gasoline Egine (EN-99729-13100_K15-K25_1112A)

Format: PDF, 238 pages

Language: English

Table of Contents:

HOW TO USE THIS MANUAL

Description

Definition of Terms

Definition of Units

Description

PRECAUTIONS FOR SAFETY AND QUALITY

Safe Operation

Correct Operation

Precautions for Radio Equipment Installation

PRECAUTIONS

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and

Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

TIGHTENING TORQUE

Standard Bolt Tightening Torque

Engine Part Tightening Torque

SPECIAL SERVICE TOOLS

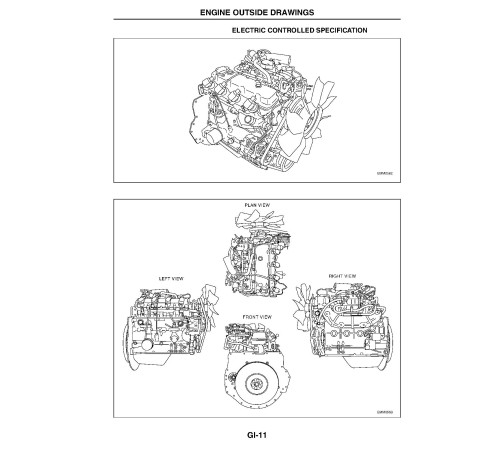

ENGINE OUTSIDE DRAWINGS

MAIN SPECIFICATIONS

STANDARD AND REPAIR LIMIT

STAMPED LOCATION OF ENGINE NO.

TROUBLE DIAGNOSIS

Engine Adjustment

Engine LPG Fuel System .

5. Operate and Maintenance manual: USA (OMM-99720-70110_0714U)

Format: PDF, 192 pages

Language: English

Table of Contents:

FOREWORD

How to Use This Manual

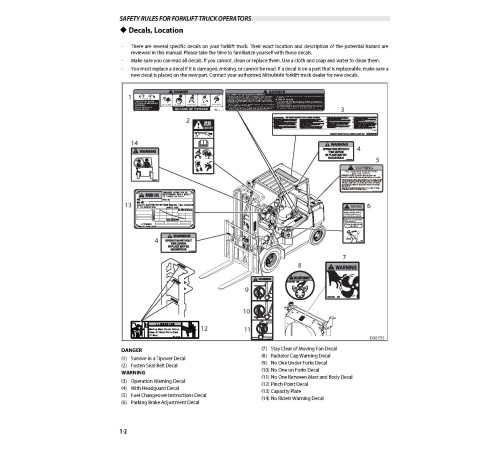

SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

General

Decals, Location

Decals, Description

Safety Rules

Operating Precautions

Working Precautions

LP-Gas

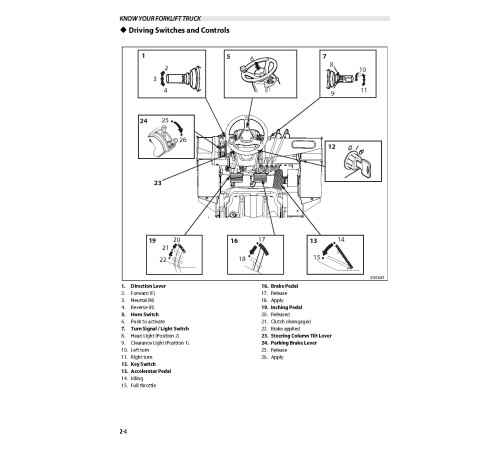

KNOW YOUR FORKLIFT TRUCK

Serial Number and Capacity Plate

Model View

Driving Switches and Controls

Meter Panel

Operating Controls

Operator Seat

Seat Belt

Engine Hood

Drawbar Pin (Option)

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What Forklift Truck Stability Is

Center of Gravity (CG)

Stability and Center of Gravity

Forklift Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

Do’s and Don’ts to Avoid Tipover

How to Survive in a Tipover

REFUELING

Gasoline and Diesel Engine Equipped

LP-Gas Equipped

OPERATION

New Forklift Truck Break-in

Before Starting Engine

Starting Engine

Engine Won't Start

After Starting Engine

Before Moving Forklift Truck

Forklift Truck Operation

Stopping Forklift Truck

Parking Forklift Truck (After Stopping)

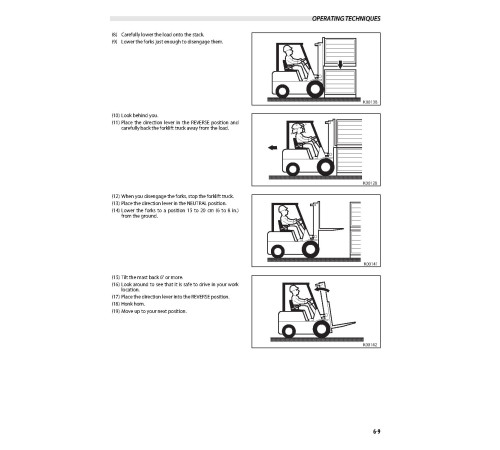

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Inching Into and Lifting the Load

Traveling with the Load

Unloading

Working on Grades

STORING THE FORKLIFT TRUCK

End of Each Shift Storage

Long Term Storage

TRANSPORTATION HINTS

Forklift Truck Loading and Shipping

Forklift Truck Lifting and Tiedown Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

Severe Dust or Lint Conditions

TROUBLESHOOTING

If a Tire Blows Out

Changing Tires

Stalled Engine

If the Warning Lamps Light

Trouble with the LP-Gas Equipment

Starting with Jumper Cables

If Lamps Won't Glow

If the Forklift Truck Won't Change Directions

If the Mast Stops Moving

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

One Month (30 days) or 200 Service Hours after Delivery of a New Truck, Whichever Comes First

Every 500 Service Hours or 3 Months, Whichever Comes First

Every 1000 Service Hours or 6 Months, Whichever Comes First

Every 2000 Service Hours or 1 Year, Whichever Comes First

SERVICE DATA

Fuel Information

Coolant Information

Recommended Fuels and Oils

Specifications (Standard Models)

Refill Capacities

Capacities and Forklift Truck Weight (Standard Models)

TO THE MITSUBISHI FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Instructions for Ordering Parts

Service Registration

COVER

6. Operate and Maintenance manual: Asia, Europe, USA (OMM-99720-70120_0318AEU)

Format: PDF, 188 pages

Language: English

Publication Date: 01 Mar 2018

This manuals will assist you in diagnosing, analyses, testing, repair, repairing engine, operating, and maintaining for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FG20S (CF54-10011-up)

FG25S (CF54-50011-up)

FG30S (CF55-10011-up)

The manual comprises 6 documents, including two Service Manuals, two Engine Technical Manuals, and two Operate and Maintenance manuals

1. Service Manual: Asia (SM-99729-10120_1117A)

Format: PDF, 479 pages

Language: English

2. Service Manual: Asia, Europe, USA (SM-99729-10110_0318AEU)

Format: PDF, 479 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Applicable Truck Model

Serial Number Locations

Dimensions

Technical Data

Performance

COOLING SYSTEM

Specifications

Structure

Removing Fan Belt

Installing Fan Belt

Inspecting and Adjusting Cooling System

ELECTRICAL SYSTEM

Electrical Components and Wiring Outline

Console Box

Meter Panel

Main Electrical Components

Battery and Maintenance

Wire Color

Troubleshooting

POWER TRAIN

Installation of Engine and Transmission Assembly (for Dual Gas/LPG Models)

Installation of Engine and Transmission Assembly (for Diesel Model)

POWERSHIFT TRANSMISSION

Structure

Removing Transmission

Installing Transmission

Disassembling Torque ConverterTransmission

Assembling Torque Converter Transmission

Disassembling Control Valve

Assembling Control Valve

Inspection and Adjustment

Troubleshooting

Service Data

FRONT AXLE AND REDUCTION DIFFERENTIAL

Structure

Removing Front Wheels

Installing Front Wheels

Removing Front Axle and Reduction Differential

Installing Front Axle

Disassembling Front Axle

Inspection and Repair After Disassembling Front Axle

Assembling Front Axle

Disassembling Reduction Differential

Inspection and Repair After Disassembling Reduction Differential

Assembling Reduction Differential

Troubleshooting

Service Data

REAR AXLE

Rear Axle Structure

Removing Rear Wheels

Installing Rear Wheels

Removing Rear Axle Assembly

Inspection and Repair After Disassembling Rear Axle Assembly

Installing Axle Assembly

Disassembling Wheel Hub

Inspection and Repair After Disassembling Wheel Hub Section

Assembling Wheel Hub Section

Disassembling Knuckle Section (Kingpin)

Inspection After Disassembly Knuckle Section (Kingpin)

Assembling Knuckle Section (Kingpin)

Removing Steering Cylinder

Disassembling Steering Cylinder

Inspection and Repair After Disassembling Steering Cylinder

Assembling Steering Cylinder

Disassembling Tie Rod

Assembling Tie Rod

BRAKE SYSTEM

Structure of Brake System

Disassembling Master Cylinder

Inspection and Repair After Disassembling Master Cylinder

Assembling Master Cylinder.

Structure of Wheel Brakes

Disassembling Wheel Brakes

Inspection and Repair After Disassembling Wheel Brakes

Assembling Wheel Brakes

Disassembling Wheel Cylinder

Inspection and Repair After Disassembling Wheel Cylinder

Assembling Wheel Cylinder.

Inspecting and Adjusting Brake System

Troubleshooting

Service Data

STEERING SYSTEM

Structure and Functions

Disassembling and Assembling Pipes and Hoses

Disassembling Steering Wheel and Steering Valve

Installing Steering Wheel and Steering Valve

Installation

Removing Steering Valve

Installing Steering Valve

Disassembling Tilt Lock Lever

Assembling Tilt Lock Lever

Disassembling Steering Valve

Inspection After Disassembly

Assembling Steering Valve

Troubleshooting

Service Data

HYDRAULIC SYSTEM

Structure and Functions

Removing Hydraulic Pump

Installing Hydraulic Pump

Disassembling Hydraulic Pump

Inspecting and Repairing Hydraulic Pump

Assembling Hydraulic Pump

Removing Lift Cylinders

Disassembling Lift Cylinder (First Cylinder for Duplex and Triplex Masts)

Inspecting Lift Cylinder (First Cylinder for Duplex and Triplex Masts)

Assembling Lift Cylinders (First Cylinder for Duplex and Triplex Masts)

Disassembling Lift Cylinder (Second Cylinder for Simplex Mast and Triplex Mast)

Inspecting Lift Cylinder (Second Cylinder for Simplex Mast and Triplex Mast)

Assembling Lift Cylinders (Second Cylinder for Simplex Mast and Triplex Mast)

Removing Tilt Cylinders

Installing Tilt Cylinders

Disassembling Tilt Cylinder

Inspection After Disassembling Tilt Cylinder

Assembling Tilt Cylinder

Piping

Removing Suction Strainer and Return Filter

Inspecting Suction Strainer and Return Filter

Installing Suction Strainer and Return Filter

Inspection and Adjustment

Troubleshooting

Service Data

Outline of Control Valve

Removing Control Valve

Installing Control Valve

Disassembling Control Valve - Inlet Section

Disassembling Control Valve - Lift Valve

Disassembling Control Valve - Tilt Valve

Disassembling Control Valve - End Cover Section

Disassembling Control Valve - End Cover Section

Assembling Control Valve - End Cover Section

Assembling AttachmentSection (Option)

MAST AND FORKS

Simplex Mast

Duplex Mast

Triplex Mast

SERVICE DATA

Maintenance Schedule

Tightening Torques for Standard Bolts and Nuts

Periodic Replacement Parts

Lubrication Schedule

Special tools

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM FOR DUAL GAS/LPG ENGINE MODELS

CIRCUIT DIAGRAM FOR DIESEL ENGINE MODELS

3. Engine Technical Manual: GK15, GK21, GK25 Gasoline Engine (EN-99789-73100_GK15-GK21-GK25_1118AEU)

Format: PDF, 128 pages

Language: English

Table of Contents:

GENERAL INFORMATION

MAINTENANCE

ENGINE TUNE-UP

ENGINE MECHANICAL

ENGINE LUBRICATION & COOLING SYSTEMS

ENGINE FUEL

ENGINE ELECTRICAL

4. Engine Technical Manual: K15, K21, K25 Gasoline Egine (EN-99729-13100_K15-K25_1112A)

Format: PDF, 238 pages

Language: English

Table of Contents:

HOW TO USE THIS MANUAL

Description

Definition of Terms

Definition of Units

Description

PRECAUTIONS FOR SAFETY AND QUALITY

Safe Operation

Correct Operation

Precautions for Radio Equipment Installation

PRECAUTIONS

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and

Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

TIGHTENING TORQUE

Standard Bolt Tightening Torque

Engine Part Tightening Torque

SPECIAL SERVICE TOOLS

ENGINE OUTSIDE DRAWINGS

MAIN SPECIFICATIONS

STANDARD AND REPAIR LIMIT

STAMPED LOCATION OF ENGINE NO.

TROUBLE DIAGNOSIS

Engine Adjustment

Engine LPG Fuel System .

5. Operate and Maintenance manual: USA (OMM-99720-70110_0714U)

Format: PDF, 192 pages

Language: English

Table of Contents:

FOREWORD

How to Use This Manual

SAFETY RULES FOR FORKLIFT TRUCK OPERATORS

General

Decals, Location

Decals, Description

Safety Rules

Operating Precautions

Working Precautions

LP-Gas

KNOW YOUR FORKLIFT TRUCK

Serial Number and Capacity Plate

Model View

Driving Switches and Controls

Meter Panel

Operating Controls

Operator Seat

Seat Belt

Engine Hood

Drawbar Pin (Option)

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What Forklift Truck Stability Is

Center of Gravity (CG)

Stability and Center of Gravity

Forklift Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

Do’s and Don’ts to Avoid Tipover

How to Survive in a Tipover

REFUELING

Gasoline and Diesel Engine Equipped

LP-Gas Equipped

OPERATION

New Forklift Truck Break-in

Before Starting Engine

Starting Engine

Engine Won't Start

After Starting Engine

Before Moving Forklift Truck

Forklift Truck Operation

Stopping Forklift Truck

Parking Forklift Truck (After Stopping)

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Inching Into and Lifting the Load

Traveling with the Load

Unloading

Working on Grades

STORING THE FORKLIFT TRUCK

End of Each Shift Storage

Long Term Storage

TRANSPORTATION HINTS

Forklift Truck Loading and Shipping

Forklift Truck Lifting and Tiedown Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

Severe Dust or Lint Conditions

TROUBLESHOOTING

If a Tire Blows Out

Changing Tires

Stalled Engine

If the Warning Lamps Light

Trouble with the LP-Gas Equipment

Starting with Jumper Cables

If Lamps Won't Glow

If the Forklift Truck Won't Change Directions

If the Mast Stops Moving

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

One Month (30 days) or 200 Service Hours after Delivery of a New Truck, Whichever Comes First

Every 500 Service Hours or 3 Months, Whichever Comes First

Every 1000 Service Hours or 6 Months, Whichever Comes First

Every 2000 Service Hours or 1 Year, Whichever Comes First

SERVICE DATA

Fuel Information

Coolant Information

Recommended Fuels and Oils

Specifications (Standard Models)

Refill Capacities

Capacities and Forklift Truck Weight (Standard Models)

TO THE MITSUBISHI FORKLIFT TRUCK OWNER

The Importance of Genuine Parts

Instructions for Ordering Parts

Service Registration

COVER

6. Operate and Maintenance manual: Asia, Europe, USA (OMM-99720-70120_0318AEU)

Format: PDF, 188 pages

Language: English

Publication Date: 01 Mar 2018

Included

Service Manual

2Engine Technical Manual

2Operate and Maintenance manual

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары