Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FBC22N2 (AFB30-00011-up), FBC25N2 (AFB30-50001-up), FBC25EN2 (AFB31-00011-up), FBC25LN2 (AFB31-30001-up), FBC30N2 (AFB31-50001-up) and FBC30LN2 (AFB32-00011-up).

This manuals will assist you in operating, maintaining, troubleshooting, and repairing for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC22N2 (AFB30-00011-up)

FBC25N2 (AFB30-50001-up)

FBC25EN2 (AFB31-00011-up)

FBC25LN2 (AFB31-30001-up)

FBC30N2 (AFB31-50001-up)

FBC30LN2 (AFB32-00011-up)

The manual comprises 18 documents, including the Operate and Maintenance manual, Wiring Diagram, and 16 Special Instructions

1. Operate and Maintenance manual (OMM-99750-7N100)

Format: PDF, 196 pages

Language: English

Table of Contents:

FOREWORD

How to Use This Manual

SAFETY RULES FOR

General

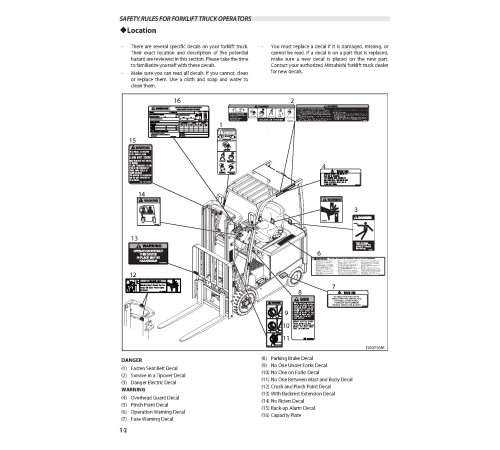

Location

Decals, Description

Safety Rules

Operating Precautions

Working Precautions

KNOW YOUR

Serial Number and Capacity Plate

Electrical Components

Model View

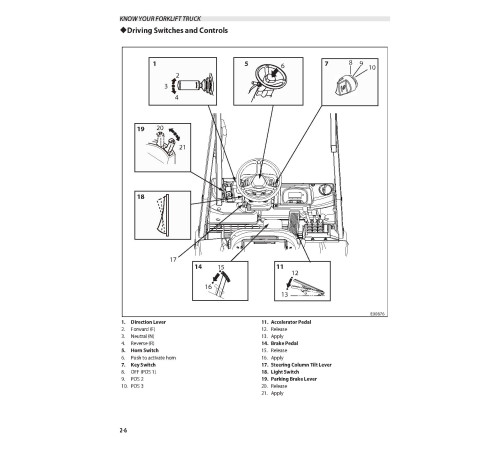

Driving Switches and Controls

Meter Panel

Parking Brake Warning Buzzer and Icon

Operating Switches and Controls (MC Model)

Operator Seat

Seat Belt

Fork Locking Pins

Changing Forks

Assist Grip

Battery Cover

Hydraulic Tank Oil Level / Filler Hole

Brake Reservoir Tank Fluid Level

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What

Center of Gravity (CG)

Stability and Center of Gravity (Top View)

Stability and Center of Gravity (Side View)

Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

Dos and Donts to Avoid Tipover

How to Survive in a Tipover

OPERATION

New

Before Starting

Before Moving

Truck Operation

Stopping

Parking

Leaving

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Flickering of the Interlock Indicator Icons

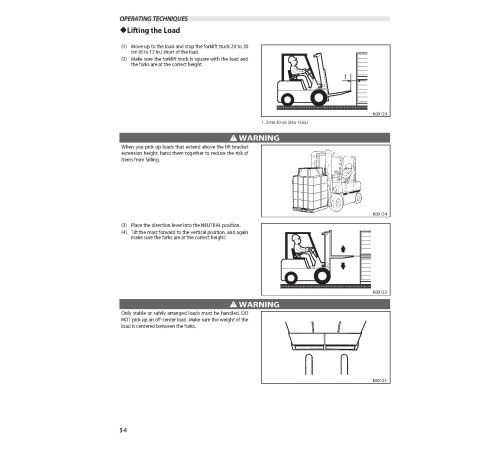

Lifting the Load

Traveling with the Load

Unloading

Working on Grades

STORING THE

End of Each Shift Storage

Long Term Storage

TRANSPORTATIONS HINTS

Truck Loading and Shipping

Truck Lifting and Tie Down Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

TROUBLESHOOTING

Fuses and Lights

Diagnostic Code List

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

Every 500 Service Hours or 3 Months, Whichever Comes First

Every 1000 Service Hours or 6 Months, Whichever Comes First

Every 2000 Service Hours or 12 Months, Whichever Comes First

Parts to Be Changed Periodically

SERVICE DATA

Recommended Oils and Greases

Specifications (Standard Models)

Capacities and

TO THE

The Importance of Genuine Parts

Proper Disposal of Your

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report for

APPENDIX

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

Circuit Diagram

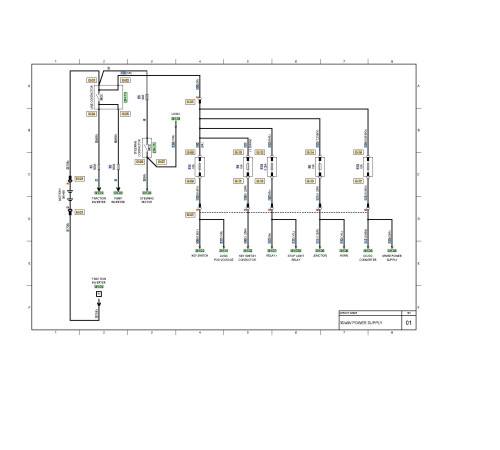

2. Wiring Diagram (EL-99759-7N100)

Format: PDF, 19 pages

Language: English

3. Special Instruction: Truck Travels When FNR Lever is in Neutral Position (000014-14M_52292)

Format: PDF, 5 pages

Language: English

4. Special Instruction: Adjusting Hydraulic Switches (000004-13M_51324)

Format: PDF, 5 pages

Language: English

5. Special Instruction: Brake Pedal Adjustment (000005-13M_51326)

Format: PDF, 4 pages

Language: English

6. Special Instruction: Hydraulic Lever Assembly Latch (000006-13M_51328)

Format: PDF, 4 pages

Language: English

7. Special Instruction: COMM ERROR on Display (000009-20M_77071)

Format: PDF, 8 pages

Language: English

8. Special Instruction: Frame Side Cover Modifications (000012-18M_65784)

Format: PDF, 13 pages

Language: English

9. Special Instruction: Operator Password Option Set Up (000013-14M_52290)

Format: PDF, 23 pages

Language: English

10. Special Instruction: adjust the brake pedal assembly (M13008_52490)

Format: PDF, 10 pages

Language: English

11. Special Instruction: Heat Sink Compound Application (000014-18M_65782)

Format: PDF, 5 pages

Language: English

12. Special Instruction: Guide for finding troubleshooting information (000016-21M_79409)

Format: PDF, 13 pages

Language: English

13. Special Instruction: Code 35 (000030-16M_57877)

Format: PDF, 5 pages

Language: English

14. Special Instruction: Electromagnetic Brake Release (000037-16M_60012)

Format: PDF, 10 pages

Language: English

15. Special Instruction: Internal Hosing Pulley (000041-18M_69569)

Format: PDF, 19 pages

Language: English

16. Special Instruction: Countermeasure for Logics Overcurrent (000044-18M_69620)

Format: PDF, 6 pages

Language: English

17. Special Instruction: Sealed Hydraulic Lever Micro Switch (000066-18M_70037)

Format: PDF, 7 pages

Language: English

18. Special Instruction: Hydraulic System Cleaning After Component Failure (000012-19M R2_74715)

Format: PDF, 13 pages

Language: English

This manuals will assist you in operating, maintaining, troubleshooting, and repairing for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FBC22N2 (AFB30-00011-up)

FBC25N2 (AFB30-50001-up)

FBC25EN2 (AFB31-00011-up)

FBC25LN2 (AFB31-30001-up)

FBC30N2 (AFB31-50001-up)

FBC30LN2 (AFB32-00011-up)

The manual comprises 18 documents, including the Operate and Maintenance manual, Wiring Diagram, and 16 Special Instructions

1. Operate and Maintenance manual (OMM-99750-7N100)

Format: PDF, 196 pages

Language: English

Table of Contents:

FOREWORD

How to Use This Manual

SAFETY RULES FOR

General

Location

Decals, Description

Safety Rules

Operating Precautions

Working Precautions

KNOW YOUR

Serial Number and Capacity Plate

Electrical Components

Model View

Driving Switches and Controls

Meter Panel

Parking Brake Warning Buzzer and Icon

Operating Switches and Controls (MC Model)

Operator Seat

Seat Belt

Fork Locking Pins

Changing Forks

Assist Grip

Battery Cover

Hydraulic Tank Oil Level / Filler Hole

Brake Reservoir Tank Fluid Level

HOW TO AVOID A TIPOVER; HOW TO SURVIVE ONE

Know What

Center of Gravity (CG)

Stability and Center of Gravity (Top View)

Stability and Center of Gravity (Side View)

Truck Stability Base

Capacity (Weight and Load Center)

Capacity Plate

Dos and Donts to Avoid Tipover

How to Survive in a Tipover

OPERATION

New

Before Starting

Before Moving

Truck Operation

Stopping

Parking

Leaving

OPERATING TECHNIQUES

Stacking Methods

Handling Loads Safely

Flickering of the Interlock Indicator Icons

Lifting the Load

Traveling with the Load

Unloading

Working on Grades

STORING THE

End of Each Shift Storage

Long Term Storage

TRANSPORTATIONS HINTS

Truck Loading and Shipping

Truck Lifting and Tie Down Information

SPECIAL SITUATIONS

Care in Cold Weather

Care in Hot Weather

TROUBLESHOOTING

Fuses and Lights

Diagnostic Code List

MAINTENANCE

General

Inspection Precautions

Maintenance Schedule

Every 10 Service Hours or Daily (Pre-Start), Whichever Comes First

Every 50 Service Hours or Weekly, Whichever Comes First

One Month (30 days) or 200 Service Hours After Delivery of a New Truck, Whichever Comes First

Every 500 Service Hours or 3 Months, Whichever Comes First

Every 1000 Service Hours or 6 Months, Whichever Comes First

Every 2000 Service Hours or 12 Months, Whichever Comes First

Parts to Be Changed Periodically

SERVICE DATA

Recommended Oils and Greases

Specifications (Standard Models)

Capacities and

TO THE

The Importance of Genuine Parts

Proper Disposal of Your

Instructions for Ordering Parts

Service Registration

Transfer of Ownership Report for

APPENDIX

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

Circuit Diagram

2. Wiring Diagram (EL-99759-7N100)

Format: PDF, 19 pages

Language: English

3. Special Instruction: Truck Travels When FNR Lever is in Neutral Position (000014-14M_52292)

Format: PDF, 5 pages

Language: English

4. Special Instruction: Adjusting Hydraulic Switches (000004-13M_51324)

Format: PDF, 5 pages

Language: English

5. Special Instruction: Brake Pedal Adjustment (000005-13M_51326)

Format: PDF, 4 pages

Language: English

6. Special Instruction: Hydraulic Lever Assembly Latch (000006-13M_51328)

Format: PDF, 4 pages

Language: English

7. Special Instruction: COMM ERROR on Display (000009-20M_77071)

Format: PDF, 8 pages

Language: English

8. Special Instruction: Frame Side Cover Modifications (000012-18M_65784)

Format: PDF, 13 pages

Language: English

9. Special Instruction: Operator Password Option Set Up (000013-14M_52290)

Format: PDF, 23 pages

Language: English

10. Special Instruction: adjust the brake pedal assembly (M13008_52490)

Format: PDF, 10 pages

Language: English

11. Special Instruction: Heat Sink Compound Application (000014-18M_65782)

Format: PDF, 5 pages

Language: English

12. Special Instruction: Guide for finding troubleshooting information (000016-21M_79409)

Format: PDF, 13 pages

Language: English

13. Special Instruction: Code 35 (000030-16M_57877)

Format: PDF, 5 pages

Language: English

14. Special Instruction: Electromagnetic Brake Release (000037-16M_60012)

Format: PDF, 10 pages

Language: English

15. Special Instruction: Internal Hosing Pulley (000041-18M_69569)

Format: PDF, 19 pages

Language: English

16. Special Instruction: Countermeasure for Logics Overcurrent (000044-18M_69620)

Format: PDF, 6 pages

Language: English

17. Special Instruction: Sealed Hydraulic Lever Micro Switch (000066-18M_70037)

Format: PDF, 7 pages

Language: English

18. Special Instruction: Hydraulic System Cleaning After Component Failure (000012-19M R2_74715)

Format: PDF, 13 pages

Language: English

Included

Operate and Maintenance manual

1Wiring Diagram

1Special Instruction

16Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары