Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FB16PNT (EFB25-00011-49999), FB18PNT (EFB26-00011-49999) and FB20PNT (EFB26-50011-99999).

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB16PNT (EFB25-00011-49999)

FB18PNT (EFB26-00011-49999)

FB20PNT (EFB26-50011-99999)

The manual comprises 5 documents, including four Service Manuals, and the Operate and Maintenance manual

1. Service Manual: Controller (SM-99759-7P110-Controller_0716)

Format: PDF, 314 pages

Language: English

Publication Date: 01 Jul 2016

Table of Contents:

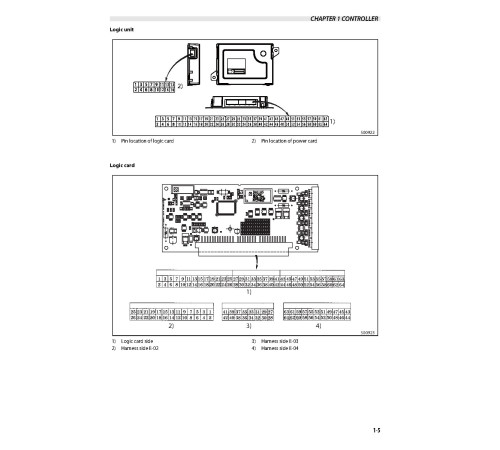

CONTROLLER

Controller System

Traction Controller Feature

Lifting Controller Feature

Other Feature

Setup Option

Diagnostics

Removal and Installation

Basic Check

AC Motor System Basics

TROUBLESHOOTING FOR CONTROL CIRCUITS

General Information

List of Diagnostic Codes

Troubleshooting

MOTOR

Motor Installation Positions

Specifications

Structures

Removing Transfer Assemblies, Traction motors

Disassembling Traction motor

Inspecting Traction Motor

Assembling Traction motor

Removing Pump Motor

Disassembling Pump Motor

Inspecting Pump Motor

Assembling Pump motor

Tightening of High-Power Cable Terminals

Removing EPS Motor

Disassembling EPS Motor

Inspecting EPS Motor

Inspecting EPS Motor

Troubleshooting

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM

2. Service Manual: Controller (SM-99759-7P100-Controller_0112)

Format: PDF, 272 pages

Language: English

Publication Date: 01 Jan 2012

Table of Contents:

CONTROLLER

Controller System

Traction Controller Feature

Lifting Controller Feature

Other Feature

Setup Option

Diagnostics

Removal and Installation

Basic Check

AC Motor System Basics

TROUBLESHOOTING FOR CONTROL CIRCUITS

General Information

List of Error Codes

Troubleshooting

MOTOR

Motor Installation Positions

Specifications

Structures

Removing Transfer Assemblies, Traction Motors

Disassembling Traction motor

Inspecting Traction Motor

Assembling Traction Motor

Removing Pump Motor

Disassembing Pump Motor

Inspecting Pump Motor

Assembling Pump motor

Tightening of High-power Cable Terminals

Removing EPS Motor

Disassembling EPS Motor

Inspecting EPS Motor

Inspecting EPS Motor

Troubleshooting

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM

3. Service Manual: Chassis & Mast (SM-99759-7M120_0716)

Format: PDF, 302 pages

Language: English

Publication Date: 01 Jul 2016

Table of Contents:

FOREWORD

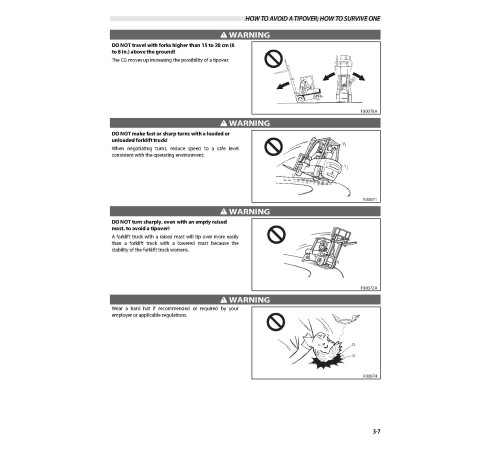

Safety

LOCKOUT/TAGOUT

How to Use This Manual

Symbols and Abbreviations

Units

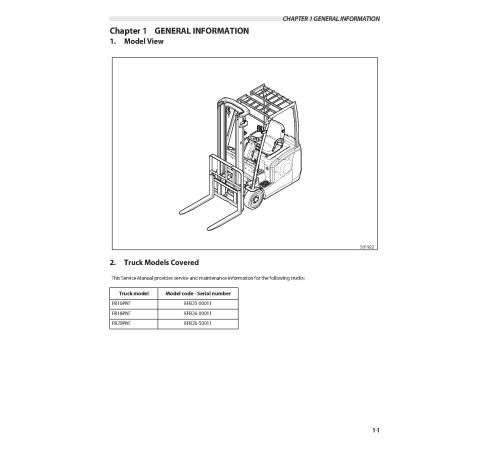

GENERAL INFORMATION

Model View

Forklift Truck Models Covered

Serial Number Locations

Specifications

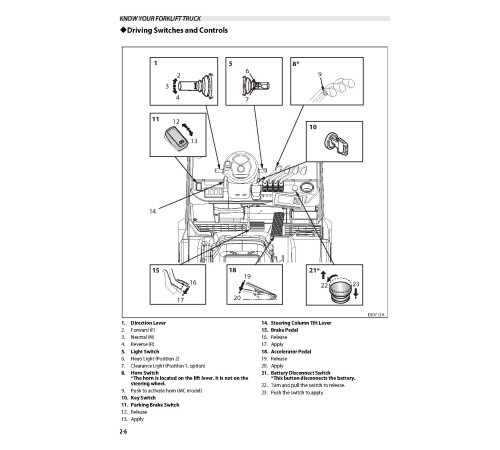

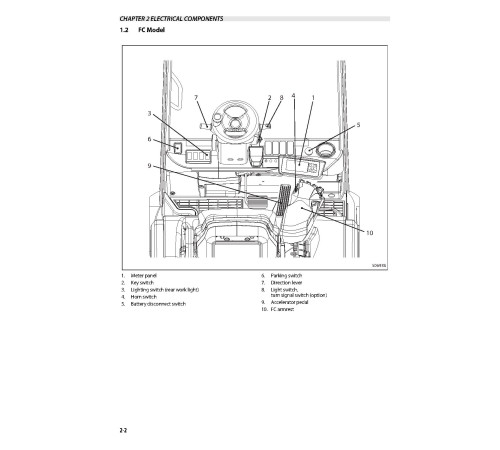

ELECTRICAL COMPONENTS

Console

Disassembling Console

Assembling Console

Meter panel

Key Switch

Lighting Switch (Rear Working Light)

Horn Switch and Battery Disconnect Switch

Troubleshooting of Lighting and Horn Systems

Parking Brake Switch

Combination Switch

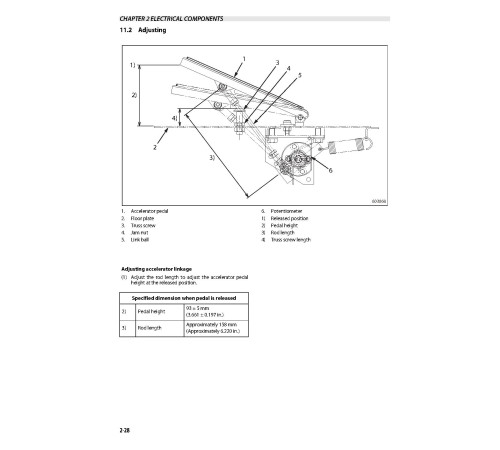

Disassembling Accelerator Control

FC Armrest

Foot Direction Control (Option)

Fuses

POWER TRAIN

Removing Battery

Removing Front Wheels

Removing Transfer Assemblies, Traction Motors

Installing Transfer Assemblies, Traction Motors and Calipers

Service Data

TRANSFER UNITS

Specifications

Structure

Disassembling Transfer Units

Inspecting Transfer Units

Assembling Transfer Units

Service Data

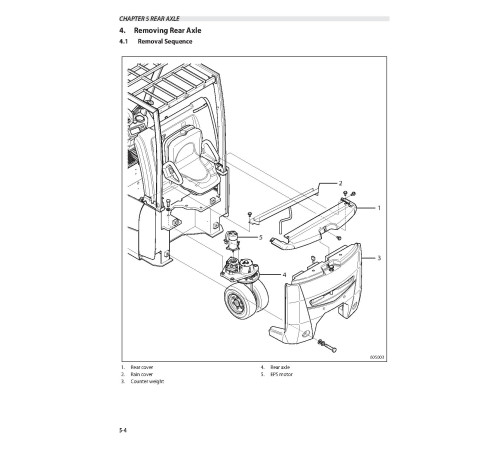

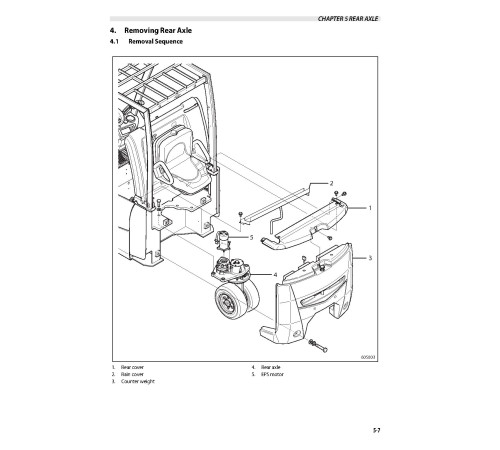

REAR AXLE

Structure

Removing Rear Wheel

Installing Rear Wheel

Removing Rear Axle

Installing Rear Axle

Disassembling Rear Axle

Assembling Rear Axle

Inspecting and Adjusting Rear Axle

Troubleshooting

Service Data

BRAKE SYSTEM

Specifications

Structure

Removing Master Cylinder

Disassembling Master Cylinder

Inspecting and Adjusting Master Cylinder

Assembling Master Cylinder

Inspecting and Adjusting Brake Pedal Assembly

Adjusting and Manual Release of Electro-Magnetic Brake

Troubleshooting

Service Data

STEERING SYSTEM

Specifications

Structure

Removing Steering Linkage Assembly

Inspecting Steering Linkage Assembly

Installing Steering Linkage Assembly

Troubleshooting

HYDRAULIC SYSTEM

Specifications

Structure

Removing Control Valve (MC Model)

Installing Control Valve

Removing Gear Pump

Installing Gear Pump

Removing Suction Filter and Return Filter

Installing Suction Filter and Return Filter

Removing Lift Cylinders (Simplex Mast)

Removing Lift Cylinders (Triplex Mast and Duplex Mast)

Installing Lift Cylinder

Removing Tilt Cylinders

Disassembling Lift cylinder

Assembling Lift Cylinder

Disassembling Tilt Cylinder

Assembling Tilt Cylinder

Inspecting and Adjusting Hydraulic System

Tests

Troubleshooting

Service Data

MC Control Valve

Construction and Function of FC Control Valve

Removing FC Control Valve

Installing FC Control Valve

Disassembly of FC Control Valve

Assembly of FC Control Valve

Valves Included in the Inlet Section

Disassembling Inlet Section

Valves Included in Tilt Section

Disassembling Tilt Section

Valves Incorporated in Attachment Section

Disassembling Attachment Section

Disassembling End Cover Plate

Cleaning

Inspecting

Precautions for Assembly

Assembling Inlet Section

Assembling Tilt Section

Assembling Attachment Section

Solenoid Control Valve

Service Data

MAST AND FORKS

Mast System

Description

Removing Simplex Mast

Installing Simplex Mast

Removing Triplex Mast, Duplex Mast

Installing Triplex Mast, Duplex Mast

Disassembling Simplex Mast

Disassembling Duplex Mast

Disassembling Triplex Mast

Inspecting Triplex Mast

Assembling Triplex Mast

Mast Height Sensor (Option)

Inspecting and Adjusting Mast and Forks

Troubleshooting

Service Data

Service Data

Inspection Standards

Periodic Replacement of Parts

Tightening Torques for Standard Bolts and Nuts

Lubrication Instructions

Weight of Major Devices

Special tools

Panel Cabin

Battery Exchange or Battery Charging

Cleaning Top Roof

Replacing Top Roof

Maintenance

4. Service Manual: Chassis & Mast (SM-99759-7M110_0415)

Format: PDF, 238 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Truck Models Covered

Serial Number Locations

Specifications

VEHICLE ELECTRICAL COMPONENTS

Console

Disassembling Console

Reassembling Console

Meter panel

Key Switch

Lighting Switch (Rear Work Lamp) (OP)

Horn Switch and Battery Disconnect Switch

Troubleshooting of Lighting and Horn Systems

Parking Brake Switch

Combination Switch

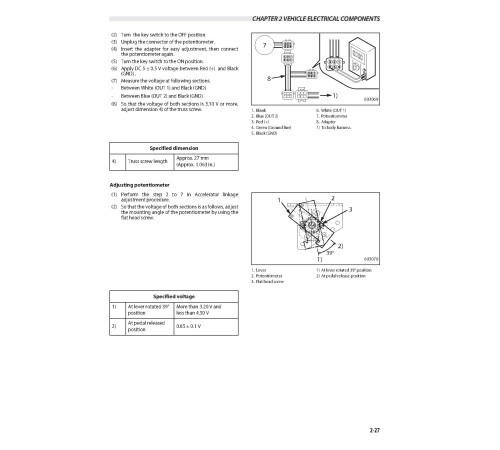

Disassembling Accelerator Control

Fuses

POWER TRAIN

Removing Batteries

Removing Front Wheels

Removing Transfer Assemblies, Traction Motors

Installing Transfer Assemblies, Traction Motors and Calipers

Service Data

TRANSFER UNITS

Specifications

Structure

Disassembling Transfer Units

Inspecting Transfer Units

Reassembling Transfer Units

Service Data

REAR AXLE

Structure

Removing Rear Wheel

Installing Rear Wheel

Removing Rear Axle

Installing Rear Axle

Disassembling Rear Axle

Reassembling Rear Axle

Inspecting and Adjusting Rear Axle

Troubleshooting

Service Data

BRAKE SYSTEM

Specifications

Structure

Removing Master Cylinder

Disassembling Master Cylinder

Inspecting and Adjusting Master Cylinder

Reassembling Master Cylinder

Inspecting and Adjusting Brake Pedal Assembly

Manually Release of Electro-Magnetic Brake

Troubleshooting

Service Data

STEERING SYSTEM

Specifications

Structure

Removing Steering Linkage Assembly

Inspecting Steering Linkage Assembly

Installing Steering Linkage Assembly

Troubleshooting

HYDRAULIC SYSTEM

Specifications

Structure

Removing Control Valve (MC Model)

Installing Control Valve

Removing Gear Pump

Installing Gear Pump

Removing Suction Filter and Return Filter

Installing Suction Filter and Return Filter

Removing Lift Cylinders (Simplex Mast)

Removing Lift Cylinders (Triplex Mast and Duplex Mast)

Installing Lift Cylinder

Removing Tilt Cylinders

Disassembling Lift cylinder

Reassembling Lift Cylinder

Disassembling Tilt Cylinder

Reassembling Tilt Cylinder

Inspecting and Adjusting Hydraulic System

Tests

Troubleshooting

Service Data

MC Control Valve

MAST AND FORKS

Mast System

Description

Removing Simplex Mast

Installing Simplex Mast

Removing Triplex Mast, Duplex Mast

Installing Triplex Mast, Duplex Mast

Disassembling Simplex Mast

Disassembling Duplex Mast

Disassembling Triplex Mast

Inspecting Triplex Mast

Reassembling Triplex Mast

Inspecting and Adjusting Mast and Forks

Troubleshooting

Service Data

Service Data

Inspection Standards

Periodic Replacement of Parts

Tightening Torques for Standard Bolts and Nuts

Lubrication Instructions

Weight of Major Devices

Special tools .

5. Operate and Maintenance manual (OMM-99750-7M100_0412)

Format: PDF, 212 pages

Language: English

Table of Contents:

FOREWORD

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB16PNT (EFB25-00011-49999)

FB18PNT (EFB26-00011-49999)

FB20PNT (EFB26-50011-99999)

The manual comprises 5 documents, including four Service Manuals, and the Operate and Maintenance manual

1. Service Manual: Controller (SM-99759-7P110-Controller_0716)

Format: PDF, 314 pages

Language: English

Publication Date: 01 Jul 2016

Table of Contents:

CONTROLLER

Controller System

Traction Controller Feature

Lifting Controller Feature

Other Feature

Setup Option

Diagnostics

Removal and Installation

Basic Check

AC Motor System Basics

TROUBLESHOOTING FOR CONTROL CIRCUITS

General Information

List of Diagnostic Codes

Troubleshooting

MOTOR

Motor Installation Positions

Specifications

Structures

Removing Transfer Assemblies, Traction motors

Disassembling Traction motor

Inspecting Traction Motor

Assembling Traction motor

Removing Pump Motor

Disassembling Pump Motor

Inspecting Pump Motor

Assembling Pump motor

Tightening of High-Power Cable Terminals

Removing EPS Motor

Disassembling EPS Motor

Inspecting EPS Motor

Inspecting EPS Motor

Troubleshooting

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM

2. Service Manual: Controller (SM-99759-7P100-Controller_0112)

Format: PDF, 272 pages

Language: English

Publication Date: 01 Jan 2012

Table of Contents:

CONTROLLER

Controller System

Traction Controller Feature

Lifting Controller Feature

Other Feature

Setup Option

Diagnostics

Removal and Installation

Basic Check

AC Motor System Basics

TROUBLESHOOTING FOR CONTROL CIRCUITS

General Information

List of Error Codes

Troubleshooting

MOTOR

Motor Installation Positions

Specifications

Structures

Removing Transfer Assemblies, Traction Motors

Disassembling Traction motor

Inspecting Traction Motor

Assembling Traction Motor

Removing Pump Motor

Disassembing Pump Motor

Inspecting Pump Motor

Assembling Pump motor

Tightening of High-power Cable Terminals

Removing EPS Motor

Disassembling EPS Motor

Inspecting EPS Motor

Inspecting EPS Motor

Troubleshooting

HOW TO READ CIRCUIT DIAGRAMS

Description of Circuit Diagrams

How to Read Circuit Diagrams

How to Read Connector Diagrams

CIRCUIT DIAGRAM

3. Service Manual: Chassis & Mast (SM-99759-7M120_0716)

Format: PDF, 302 pages

Language: English

Publication Date: 01 Jul 2016

Table of Contents:

FOREWORD

Safety

LOCKOUT/TAGOUT

How to Use This Manual

Symbols and Abbreviations

Units

GENERAL INFORMATION

Model View

Forklift Truck Models Covered

Serial Number Locations

Specifications

ELECTRICAL COMPONENTS

Console

Disassembling Console

Assembling Console

Meter panel

Key Switch

Lighting Switch (Rear Working Light)

Horn Switch and Battery Disconnect Switch

Troubleshooting of Lighting and Horn Systems

Parking Brake Switch

Combination Switch

Disassembling Accelerator Control

FC Armrest

Foot Direction Control (Option)

Fuses

POWER TRAIN

Removing Battery

Removing Front Wheels

Removing Transfer Assemblies, Traction Motors

Installing Transfer Assemblies, Traction Motors and Calipers

Service Data

TRANSFER UNITS

Specifications

Structure

Disassembling Transfer Units

Inspecting Transfer Units

Assembling Transfer Units

Service Data

REAR AXLE

Structure

Removing Rear Wheel

Installing Rear Wheel

Removing Rear Axle

Installing Rear Axle

Disassembling Rear Axle

Assembling Rear Axle

Inspecting and Adjusting Rear Axle

Troubleshooting

Service Data

BRAKE SYSTEM

Specifications

Structure

Removing Master Cylinder

Disassembling Master Cylinder

Inspecting and Adjusting Master Cylinder

Assembling Master Cylinder

Inspecting and Adjusting Brake Pedal Assembly

Adjusting and Manual Release of Electro-Magnetic Brake

Troubleshooting

Service Data

STEERING SYSTEM

Specifications

Structure

Removing Steering Linkage Assembly

Inspecting Steering Linkage Assembly

Installing Steering Linkage Assembly

Troubleshooting

HYDRAULIC SYSTEM

Specifications

Structure

Removing Control Valve (MC Model)

Installing Control Valve

Removing Gear Pump

Installing Gear Pump

Removing Suction Filter and Return Filter

Installing Suction Filter and Return Filter

Removing Lift Cylinders (Simplex Mast)

Removing Lift Cylinders (Triplex Mast and Duplex Mast)

Installing Lift Cylinder

Removing Tilt Cylinders

Disassembling Lift cylinder

Assembling Lift Cylinder

Disassembling Tilt Cylinder

Assembling Tilt Cylinder

Inspecting and Adjusting Hydraulic System

Tests

Troubleshooting

Service Data

MC Control Valve

Construction and Function of FC Control Valve

Removing FC Control Valve

Installing FC Control Valve

Disassembly of FC Control Valve

Assembly of FC Control Valve

Valves Included in the Inlet Section

Disassembling Inlet Section

Valves Included in Tilt Section

Disassembling Tilt Section

Valves Incorporated in Attachment Section

Disassembling Attachment Section

Disassembling End Cover Plate

Cleaning

Inspecting

Precautions for Assembly

Assembling Inlet Section

Assembling Tilt Section

Assembling Attachment Section

Solenoid Control Valve

Service Data

MAST AND FORKS

Mast System

Description

Removing Simplex Mast

Installing Simplex Mast

Removing Triplex Mast, Duplex Mast

Installing Triplex Mast, Duplex Mast

Disassembling Simplex Mast

Disassembling Duplex Mast

Disassembling Triplex Mast

Inspecting Triplex Mast

Assembling Triplex Mast

Mast Height Sensor (Option)

Inspecting and Adjusting Mast and Forks

Troubleshooting

Service Data

Service Data

Inspection Standards

Periodic Replacement of Parts

Tightening Torques for Standard Bolts and Nuts

Lubrication Instructions

Weight of Major Devices

Special tools

Panel Cabin

Battery Exchange or Battery Charging

Cleaning Top Roof

Replacing Top Roof

Maintenance

4. Service Manual: Chassis & Mast (SM-99759-7M110_0415)

Format: PDF, 238 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Model View

Truck Models Covered

Serial Number Locations

Specifications

VEHICLE ELECTRICAL COMPONENTS

Console

Disassembling Console

Reassembling Console

Meter panel

Key Switch

Lighting Switch (Rear Work Lamp) (OP)

Horn Switch and Battery Disconnect Switch

Troubleshooting of Lighting and Horn Systems

Parking Brake Switch

Combination Switch

Disassembling Accelerator Control

Fuses

POWER TRAIN

Removing Batteries

Removing Front Wheels

Removing Transfer Assemblies, Traction Motors

Installing Transfer Assemblies, Traction Motors and Calipers

Service Data

TRANSFER UNITS

Specifications

Structure

Disassembling Transfer Units

Inspecting Transfer Units

Reassembling Transfer Units

Service Data

REAR AXLE

Structure

Removing Rear Wheel

Installing Rear Wheel

Removing Rear Axle

Installing Rear Axle

Disassembling Rear Axle

Reassembling Rear Axle

Inspecting and Adjusting Rear Axle

Troubleshooting

Service Data

BRAKE SYSTEM

Specifications

Structure

Removing Master Cylinder

Disassembling Master Cylinder

Inspecting and Adjusting Master Cylinder

Reassembling Master Cylinder

Inspecting and Adjusting Brake Pedal Assembly

Manually Release of Electro-Magnetic Brake

Troubleshooting

Service Data

STEERING SYSTEM

Specifications

Structure

Removing Steering Linkage Assembly

Inspecting Steering Linkage Assembly

Installing Steering Linkage Assembly

Troubleshooting

HYDRAULIC SYSTEM

Specifications

Structure

Removing Control Valve (MC Model)

Installing Control Valve

Removing Gear Pump

Installing Gear Pump

Removing Suction Filter and Return Filter

Installing Suction Filter and Return Filter

Removing Lift Cylinders (Simplex Mast)

Removing Lift Cylinders (Triplex Mast and Duplex Mast)

Installing Lift Cylinder

Removing Tilt Cylinders

Disassembling Lift cylinder

Reassembling Lift Cylinder

Disassembling Tilt Cylinder

Reassembling Tilt Cylinder

Inspecting and Adjusting Hydraulic System

Tests

Troubleshooting

Service Data

MC Control Valve

MAST AND FORKS

Mast System

Description

Removing Simplex Mast

Installing Simplex Mast

Removing Triplex Mast, Duplex Mast

Installing Triplex Mast, Duplex Mast

Disassembling Simplex Mast

Disassembling Duplex Mast

Disassembling Triplex Mast

Inspecting Triplex Mast

Reassembling Triplex Mast

Inspecting and Adjusting Mast and Forks

Troubleshooting

Service Data

Service Data

Inspection Standards

Periodic Replacement of Parts

Tightening Torques for Standard Bolts and Nuts

Lubrication Instructions

Weight of Major Devices

Special tools .

5. Operate and Maintenance manual (OMM-99750-7M100_0412)

Format: PDF, 212 pages

Language: English

Table of Contents:

FOREWORD