Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FB10CA (221AE0001-up), FB10HCA (221AE0001-up), FB14CA (221AE0001-up), FB14HCA (221AE0001-up), FB15CA (221AE0001-up), FB15HCA (221AE0001-up), FB18CA (221AE0001-up), FB18HCA (221AE0001-up), FB20CA (241AC0001-up), FB25CA (241AC0001-up), FB25HCA (241AC0001-up), FB28CA (241AC0001-up) and FB30CA (251AC0001-up).

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB10CA (221AE0001-up)

FB10HCA (221AE0001-up)

FB14CA (221AE0001-up)

FB14HCA (221AE0001-up)

FB15CA (221AE0001-up)

FB15HCA (221AE0001-up)

FB18CA (221AE0001-up)

FB18HCA (221AE0001-up)

FB20CA (241AC0001-up)

FB25CA (241AC0001-up)

FB25HCA (241AC0001-up)

FB28CA (241AC0001-up)

FB30CA (251AC0001-up)

The manual comprises 3 documents, including two Service Manuals, and the Operate and Maintenance manual

1. Service Manual: Controller (SM-99N19-53100_Controller_E08)

Format: PDF, 113 pages

Language: English

Table of Contents:

Introduction

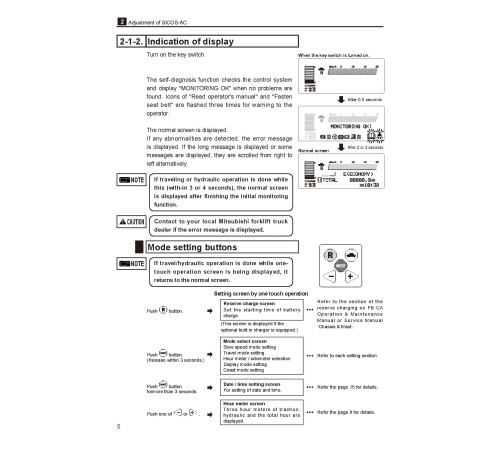

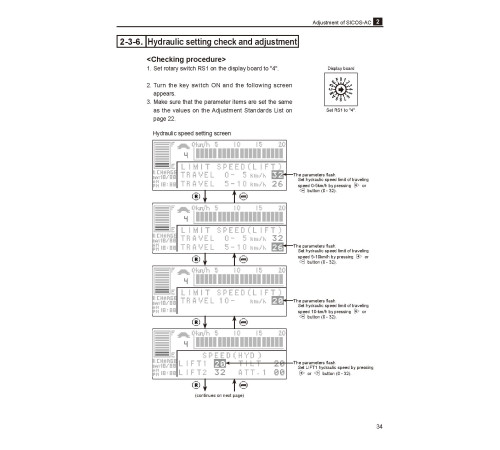

Adjustment of SICOS-AC

Troubleshooting

Wiring and main controller layout

2. Service Manual: Chassis, Mast (SM-99N19-51100_E08)

Format: PDF, 211 pages

Language: English

Table of Contents:

1 .GENERAL

1-1. Appearance

1-2. Specifications

2 .FRONT AXLE (DRIVE)

2-1. Location and name

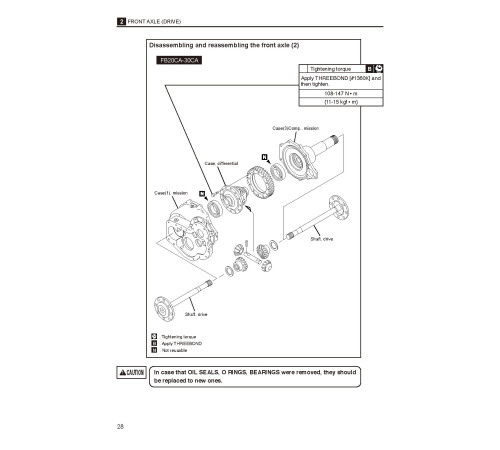

2-2. Disassembly and reassembly

2-2-1. Front axle - removal and installation

2-2-2. Front axle - disassembly and reassembly

2-3. Inspection and adjustment

2-3-1. Gears - Inspection and replacement

2-3-2. Wheel hub and hub bolt - Inspection

2-4. Troubleshooting

2-4-1. Front axle - troubleshooting

3 .REAR AXLE (STEERING)

3-1. Location and name

3-2. Disassembly and reassembly

3-2-1. Rear axle - removal and installation

3-2-2. Rear axle - disassembly and reassembly

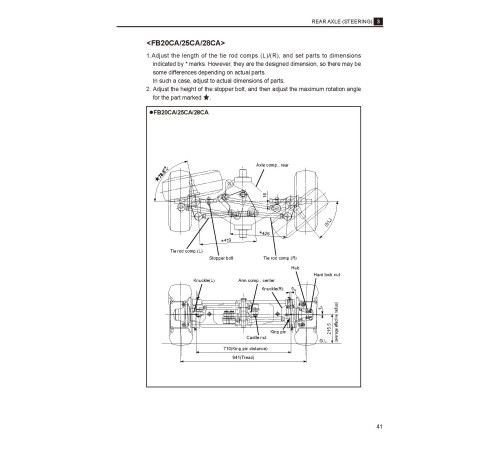

3-2-3. Rear axle assembly - methods and precautions

3-3. Inspection and adjustmentv

3-3-1. Bushing - inspection

3-3-2. Center arm - inspection

3-3-3. Tie rod comp. - inspection

3-3-4. Knuckle - inspection

3-3-5. King pin - inspection

3-3-6. Hub and hub bolt - inspection

3-3-7. Rear axle comp. - inspection

3-4. Troubleshooting

3-4-1. Rear axle - troubleshooting

4 .TYRE

4-1. Location, name and tyre size

4-1-1. Tyre - location and name

4-1-2. Tyre size

4-2. Inspection and adjustment

4-2-1. Hub nut - inspection

4-2-2. Rim and rim bolt - inspection

4-2-3. Air pressure - inspection

4-2-4. Tyre - visual inspection and replacement

4-3. Troubleshooting

4-3-1. Tyre - troubleshooting

5. STEERING

5-1. Location and name

5-2. Disassembly and reassembly

5-2-1. Steering - removal and installation

5-2-2. Steering linkage - disassembly and reassembly

5-3. Inspection and adjustment

5-3-1. Joint - inspection and replacement

5-3-2. Knob - inspection and replacement

5-3-3. Steering wheel - inspection and replacement

5-3-4. Torque sensor neutral - check and adjustment

5-3-5. Checking by voltage

5-4. Troubleshooting

5-4-1. Steering linkage - troubleshooting

6. BRAKE

6-1. Location and name

6-1-1. Foot brake linkage - main part names

6-1-2. Parking brake linkage - main part names

6-2. Disassembly and reassembly

6-2-1. Wheel brake - removal and installation

6-2-2. Wheel brake - disassembly and reassembly

6-3. Inspection and adjustment

6-3-1. Brake drum - inspection, repair and replacement

6-3-2. Shoe & lining - inspection and replacement

6-3-3. Adjustor ass`y - inspection and replacement

6-3-4. Wheel cylinder ass`y - inspection and replacement

6-3-5. Master cylinder ass`y - inspection and replacement

6-3-6. Brake pedal - inspection

6-3-7. Parking lever - inspection and adjustment

6-3-8. Brake linkage - adjustment

6-3-9. Discharge air from the brakes

6-4. Troubleshooting

6-4-1. Brake - troubleshooting

7. HYDRAULIC SYSTEM

7-1. Oil piping circuit

7a. HYDRAULIC PUMP

7a-1. Location and name

7a-2. Disassembly and reassembly

7a-2-1. Hydraulic pump - removal and installation

7a-3. Inspection and adjustment

7a-3-1. Hydraulic pump - inspection

7a-4. Troubleshooting

7a-4-1. Hydraulic pump - troubleshooting

7b. OIL TANK AND OIL PIPING

7b-1. Location and name

7b-1-1. Resin oil tank - main part names

7b-1-2. Iron oil tank - main part names

7b-2. Disassembly and reassembly

7b-2-1. Oil tank - precautions

7b-2-2. Oil piping replacement - precautions

7b-3. Inspection and adjustment

7b-3-1. Oil - inspection

7b-3-2. Recommended oil and oil quantity

7b-3-3. Oil tank and filters - cleaning and check

7b-4. Troubleshooting

7b-4-1. Oil tank - troubleshooting

7c. CONTROL VALVE

7c-1. Location and name

7c-2. Disassembly and reassembly

7c-2-1. Control valve - removal and installation

7c-2-2. Inner kit of control valve - replacement

7c-3. Inspection and adjustment

7c-3-1. Relief pressure - measurement

7c-3-2. Microswitch - adjustment

7c-4. Troubleshooting

7c-4-1. Control valve - troubleshooting

7d. CYLINDER

7d-1. Location and name

7d-1-1. Lift cylinder - main part names

7d-1-2. Tilt cylinder - main part names

7d-2. Disassembly and reassembly

7d-2-1. Lift cylinder (2SP mast) - removal

7d-2-2. Lift cylinder 2nd (3FP/2FP mast) - removal

7d-2-3. Tilt cylinder - removal

7d-2-4. Lift cylinder - installation and adjustment

7d-2-5. Tilt cylinder - installation

7d-2-6. Lift cylinder - disassembly and reassembly

7d-2-7. Tilt cylinder - disassembly and reassembly

7d-3. Inspection and adjustment

7d-3-1. Cylinder comp. - inspection

7d-3-2. Piston rod - inspection

7d-3-3. Drift of lift lowering and tilt - inspection

7d-4. Troubleshooting

7d-4-1. Cylinder - troubleshooting

8. MAST

8-1. Location and name

8-2. Disassembly and reassembly

8-2-1. Lift bracket - removal

8-2-2. Mast ass`y - removal

8-2-3. Mast - disassembly and reassembly

8-3. Inspection and adjustment

8-3-1. Mast, lift bracket and roller shaft - inspection

8-3-2. Back shoe - inspection

8-3-3. Lift chain - inspection and replacement

8-3-4. Chain bolt - inspection

8-3-5. Chain wheel - inspection

8-3-6. Hose pulley - inspection

8-3-7. Roller - inspection and replacement

8-3-8. Fork - inspection and replacement

8-3-9. Lift chain - inspection and adjustment

8-3-10. Mast inclination - inspection and adjustmen

8-4. Troubleshooting

8-4-1. Mast - troubleshooting

9. MOTOR

9-1. Location and name

9-1-1. Traction motor - main part names

9-1-2. Hydraulic motor - main part names

9-1-3. EPS motor - main part names

9-1-4. Motors - specifications

9-2. Disassembly and reassembly

9-2-1. Traction motor - removal and installation

9-2-2. Hydraulic motor - removal and installation

9-2-3. EPS motor - removal and installation

9-2-4. Traction motor - disassembly and reassembl

9-2-5. Hydraulic motor - disassembly and reassembly

9-2-6. EPS motor - disassembly and reassembly

9-3. Inspection and adjustment

9-3-1. Rotor comp. - inspection and replacement (Traction and hydraulic motor)

9-3-2. Armature comp. - inspection and replacement

9-3-3. Brush, brush holder and spring (EPS motor) - inspection and replacement

9-3-4. Motor ass`y - inspection (Traction motor and Hydraulic motor)

9-3-5. Motor ass`y (EPS motor) - inspection

9-3-6. Oil seal and permanent magnet (EPS motor) - inspection and replacement

9-4. Troubleshooting

9-4-1. Motor - troubleshooting

10. ELECTRIC PARTS

10-1. Location and name

10a. CONTROL UNIT

10a-1. Location and name

10a-2. Disassembly and reassembly

10a-2-1. Control unit - removal and installation

10a-2-2. Control unit - disassembly and reassembly

10a-3. Check and replacement

10a-3-1. Capacitor - discharging procedure

10a-3-2. Module, IGBT - inspection and replacement

10a-3-3. Capacitor - check and replacement

10a-3-4. EPS controller - specifications

10b. DISPLAY PANEL AND DIRECTIONALSWITCH

10b-1. Disassembly and reassembly

10b-1-1. Display panel - disassembly and reassembly

10b-1-2. Directional switch - disassembly and reassembly

10c. ACCELERATOR

10c-1. Disassembly and reassembly

10c-1-1. Accelerator linkage - removal and installation

10d. MAIN CONTACTOR AND FUSE

10d-1. Disassembly and reassembly

10d-1-1. Control unit - removal and installation

10d-2. Inspection and replacement

10d-2-1. Main contactor - inspection and replacement

10d-2-2. Fuse - replacement

10e. CHARGER

10e-1. Disassembly and reassembly

10e-1-1. Charger ass`y - disassembly and reassembly

10e-1-2. Transformer - disassembly and reassembly

10e-1-3. Built-in charger - specifications

10e-2. Inspection and replacement

10e-2-1. Magnetic contactor - inspection

10e-2-2. Plug comp. and receptacle - inspection and replacement

10e-2-3. Link fuse and fuse base - inspection

10e-2-4. Transformer - inspection

10e-2-5. Diode - inspection

10e-3. Inspection After Assembly

10e-3-1. Timer - inspection

10e-3-2. Reserve function - inspection

10e-4. Charging procedure

10e-4-1. Normal (Daily charge)

10e-4-2. Reserve charge

10e-4-3. Balancing charge

10e-5. Voltage tap

10e-5-1. Power voltage - check

10e-5-2. Voltage tap - selection

10e-5-3. Power tap - switching

10e-5-4. Link fuse (three-phase voltage) - replacement

10f. BATTERY

10f-1. Disassembly and reassembly

10f-1-1. Battery - removal and installation

10f-2. Inspection and adjustment

10f-2-1. Battery - inspection

10f-2-2. Battery - Cleaning

10g. MPU BOARD

10g-1. Location and name

10g-1-1. Travel/Hydraulic board

10g-1-2. Display board

11. LASER POINTER

11-1. Adjustment

11-1-1. Fork level - adjustment

11-1-2. Laser optical axis - adjustment

12. SERVICE DATA

12-1. Standard work hours

3. Operate and Maintenance manual (OMM-NL000006685)

Format: PDF, 118 pages

Language: English

Table of Contents:

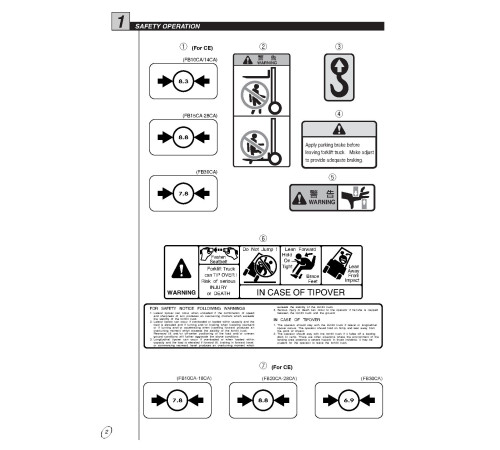

SAFETY OPERATION

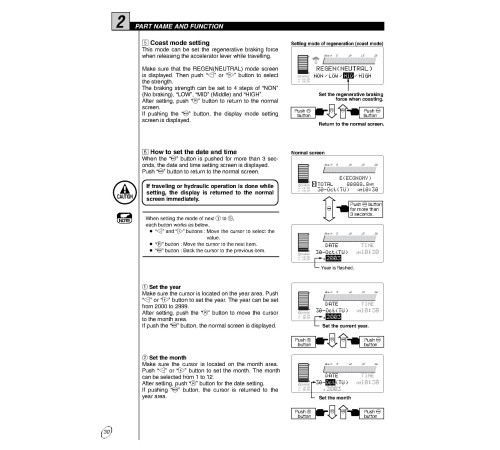

PART NAME AND FUNCTION

DRIVING AND OPERATION

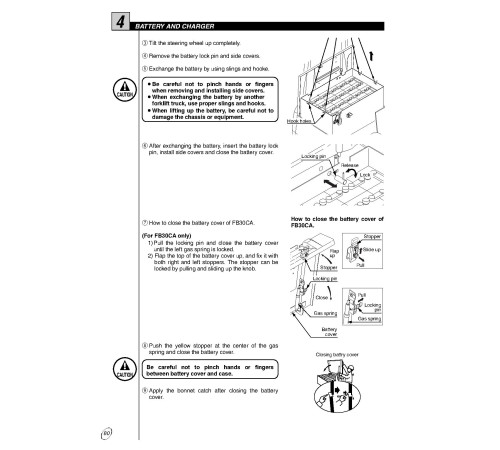

BATTERY AND CHARGER

INSPECTION PRIOR TO OPERATION

INSPECTION OF AFTER OPERATION

PERIODIC SERVICING

QUICK FAULT FINDING

PERIODICAL REPLACING PARTS

STABILITY OF FORKLIFT TRUCK

SPECIFICATIONS

COLD STORAGE TYPE FORKLIFT TRUCK

SIDESHIFT ATTACHMENT

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB10CA (221AE0001-up)

FB10HCA (221AE0001-up)

FB14CA (221AE0001-up)

FB14HCA (221AE0001-up)

FB15CA (221AE0001-up)

FB15HCA (221AE0001-up)

FB18CA (221AE0001-up)

FB18HCA (221AE0001-up)

FB20CA (241AC0001-up)

FB25CA (241AC0001-up)

FB25HCA (241AC0001-up)

FB28CA (241AC0001-up)

FB30CA (251AC0001-up)

The manual comprises 3 documents, including two Service Manuals, and the Operate and Maintenance manual

1. Service Manual: Controller (SM-99N19-53100_Controller_E08)

Format: PDF, 113 pages

Language: English

Table of Contents:

Introduction

Adjustment of SICOS-AC

Troubleshooting

Wiring and main controller layout

2. Service Manual: Chassis, Mast (SM-99N19-51100_E08)

Format: PDF, 211 pages

Language: English

Table of Contents:

1 .GENERAL

1-1. Appearance

1-2. Specifications

2 .FRONT AXLE (DRIVE)

2-1. Location and name

2-2. Disassembly and reassembly

2-2-1. Front axle - removal and installation

2-2-2. Front axle - disassembly and reassembly

2-3. Inspection and adjustment

2-3-1. Gears - Inspection and replacement

2-3-2. Wheel hub and hub bolt - Inspection

2-4. Troubleshooting

2-4-1. Front axle - troubleshooting

3 .REAR AXLE (STEERING)

3-1. Location and name

3-2. Disassembly and reassembly

3-2-1. Rear axle - removal and installation

3-2-2. Rear axle - disassembly and reassembly

3-2-3. Rear axle assembly - methods and precautions

3-3. Inspection and adjustmentv

3-3-1. Bushing - inspection

3-3-2. Center arm - inspection

3-3-3. Tie rod comp. - inspection

3-3-4. Knuckle - inspection

3-3-5. King pin - inspection

3-3-6. Hub and hub bolt - inspection

3-3-7. Rear axle comp. - inspection

3-4. Troubleshooting

3-4-1. Rear axle - troubleshooting

4 .TYRE

4-1. Location, name and tyre size

4-1-1. Tyre - location and name

4-1-2. Tyre size

4-2. Inspection and adjustment

4-2-1. Hub nut - inspection

4-2-2. Rim and rim bolt - inspection

4-2-3. Air pressure - inspection

4-2-4. Tyre - visual inspection and replacement

4-3. Troubleshooting

4-3-1. Tyre - troubleshooting

5. STEERING

5-1. Location and name

5-2. Disassembly and reassembly

5-2-1. Steering - removal and installation

5-2-2. Steering linkage - disassembly and reassembly

5-3. Inspection and adjustment

5-3-1. Joint - inspection and replacement

5-3-2. Knob - inspection and replacement

5-3-3. Steering wheel - inspection and replacement

5-3-4. Torque sensor neutral - check and adjustment

5-3-5. Checking by voltage

5-4. Troubleshooting

5-4-1. Steering linkage - troubleshooting

6. BRAKE

6-1. Location and name

6-1-1. Foot brake linkage - main part names

6-1-2. Parking brake linkage - main part names

6-2. Disassembly and reassembly

6-2-1. Wheel brake - removal and installation

6-2-2. Wheel brake - disassembly and reassembly

6-3. Inspection and adjustment

6-3-1. Brake drum - inspection, repair and replacement

6-3-2. Shoe & lining - inspection and replacement

6-3-3. Adjustor ass`y - inspection and replacement

6-3-4. Wheel cylinder ass`y - inspection and replacement

6-3-5. Master cylinder ass`y - inspection and replacement

6-3-6. Brake pedal - inspection

6-3-7. Parking lever - inspection and adjustment

6-3-8. Brake linkage - adjustment

6-3-9. Discharge air from the brakes

6-4. Troubleshooting

6-4-1. Brake - troubleshooting

7. HYDRAULIC SYSTEM

7-1. Oil piping circuit

7a. HYDRAULIC PUMP

7a-1. Location and name

7a-2. Disassembly and reassembly

7a-2-1. Hydraulic pump - removal and installation

7a-3. Inspection and adjustment

7a-3-1. Hydraulic pump - inspection

7a-4. Troubleshooting

7a-4-1. Hydraulic pump - troubleshooting

7b. OIL TANK AND OIL PIPING

7b-1. Location and name

7b-1-1. Resin oil tank - main part names

7b-1-2. Iron oil tank - main part names

7b-2. Disassembly and reassembly

7b-2-1. Oil tank - precautions

7b-2-2. Oil piping replacement - precautions

7b-3. Inspection and adjustment

7b-3-1. Oil - inspection

7b-3-2. Recommended oil and oil quantity

7b-3-3. Oil tank and filters - cleaning and check

7b-4. Troubleshooting

7b-4-1. Oil tank - troubleshooting

7c. CONTROL VALVE

7c-1. Location and name

7c-2. Disassembly and reassembly

7c-2-1. Control valve - removal and installation

7c-2-2. Inner kit of control valve - replacement

7c-3. Inspection and adjustment

7c-3-1. Relief pressure - measurement

7c-3-2. Microswitch - adjustment

7c-4. Troubleshooting

7c-4-1. Control valve - troubleshooting

7d. CYLINDER

7d-1. Location and name

7d-1-1. Lift cylinder - main part names

7d-1-2. Tilt cylinder - main part names

7d-2. Disassembly and reassembly

7d-2-1. Lift cylinder (2SP mast) - removal

7d-2-2. Lift cylinder 2nd (3FP/2FP mast) - removal

7d-2-3. Tilt cylinder - removal

7d-2-4. Lift cylinder - installation and adjustment

7d-2-5. Tilt cylinder - installation

7d-2-6. Lift cylinder - disassembly and reassembly

7d-2-7. Tilt cylinder - disassembly and reassembly

7d-3. Inspection and adjustment

7d-3-1. Cylinder comp. - inspection

7d-3-2. Piston rod - inspection

7d-3-3. Drift of lift lowering and tilt - inspection

7d-4. Troubleshooting

7d-4-1. Cylinder - troubleshooting

8. MAST

8-1. Location and name

8-2. Disassembly and reassembly

8-2-1. Lift bracket - removal

8-2-2. Mast ass`y - removal

8-2-3. Mast - disassembly and reassembly

8-3. Inspection and adjustment

8-3-1. Mast, lift bracket and roller shaft - inspection

8-3-2. Back shoe - inspection

8-3-3. Lift chain - inspection and replacement

8-3-4. Chain bolt - inspection

8-3-5. Chain wheel - inspection

8-3-6. Hose pulley - inspection

8-3-7. Roller - inspection and replacement

8-3-8. Fork - inspection and replacement

8-3-9. Lift chain - inspection and adjustment

8-3-10. Mast inclination - inspection and adjustmen

8-4. Troubleshooting

8-4-1. Mast - troubleshooting

9. MOTOR

9-1. Location and name

9-1-1. Traction motor - main part names

9-1-2. Hydraulic motor - main part names

9-1-3. EPS motor - main part names

9-1-4. Motors - specifications

9-2. Disassembly and reassembly

9-2-1. Traction motor - removal and installation

9-2-2. Hydraulic motor - removal and installation

9-2-3. EPS motor - removal and installation

9-2-4. Traction motor - disassembly and reassembl

9-2-5. Hydraulic motor - disassembly and reassembly

9-2-6. EPS motor - disassembly and reassembly

9-3. Inspection and adjustment

9-3-1. Rotor comp. - inspection and replacement (Traction and hydraulic motor)

9-3-2. Armature comp. - inspection and replacement

9-3-3. Brush, brush holder and spring (EPS motor) - inspection and replacement

9-3-4. Motor ass`y - inspection (Traction motor and Hydraulic motor)

9-3-5. Motor ass`y (EPS motor) - inspection

9-3-6. Oil seal and permanent magnet (EPS motor) - inspection and replacement

9-4. Troubleshooting

9-4-1. Motor - troubleshooting

10. ELECTRIC PARTS

10-1. Location and name

10a. CONTROL UNIT

10a-1. Location and name

10a-2. Disassembly and reassembly

10a-2-1. Control unit - removal and installation

10a-2-2. Control unit - disassembly and reassembly

10a-3. Check and replacement

10a-3-1. Capacitor - discharging procedure

10a-3-2. Module, IGBT - inspection and replacement

10a-3-3. Capacitor - check and replacement

10a-3-4. EPS controller - specifications

10b. DISPLAY PANEL AND DIRECTIONALSWITCH

10b-1. Disassembly and reassembly

10b-1-1. Display panel - disassembly and reassembly

10b-1-2. Directional switch - disassembly and reassembly

10c. ACCELERATOR

10c-1. Disassembly and reassembly

10c-1-1. Accelerator linkage - removal and installation

10d. MAIN CONTACTOR AND FUSE

10d-1. Disassembly and reassembly

10d-1-1. Control unit - removal and installation

10d-2. Inspection and replacement

10d-2-1. Main contactor - inspection and replacement

10d-2-2. Fuse - replacement

10e. CHARGER

10e-1. Disassembly and reassembly

10e-1-1. Charger ass`y - disassembly and reassembly

10e-1-2. Transformer - disassembly and reassembly

10e-1-3. Built-in charger - specifications

10e-2. Inspection and replacement

10e-2-1. Magnetic contactor - inspection

10e-2-2. Plug comp. and receptacle - inspection and replacement

10e-2-3. Link fuse and fuse base - inspection

10e-2-4. Transformer - inspection

10e-2-5. Diode - inspection

10e-3. Inspection After Assembly

10e-3-1. Timer - inspection

10e-3-2. Reserve function - inspection

10e-4. Charging procedure

10e-4-1. Normal (Daily charge)

10e-4-2. Reserve charge

10e-4-3. Balancing charge

10e-5. Voltage tap

10e-5-1. Power voltage - check

10e-5-2. Voltage tap - selection

10e-5-3. Power tap - switching

10e-5-4. Link fuse (three-phase voltage) - replacement

10f. BATTERY

10f-1. Disassembly and reassembly

10f-1-1. Battery - removal and installation

10f-2. Inspection and adjustment

10f-2-1. Battery - inspection

10f-2-2. Battery - Cleaning

10g. MPU BOARD

10g-1. Location and name

10g-1-1. Travel/Hydraulic board

10g-1-2. Display board

11. LASER POINTER

11-1. Adjustment

11-1-1. Fork level - adjustment

11-1-2. Laser optical axis - adjustment

12. SERVICE DATA

12-1. Standard work hours

3. Operate and Maintenance manual (OMM-NL000006685)

Format: PDF, 118 pages

Language: English

Table of Contents:

SAFETY OPERATION

PART NAME AND FUNCTION

DRIVING AND OPERATION

BATTERY AND CHARGER

INSPECTION PRIOR TO OPERATION

INSPECTION OF AFTER OPERATION

PERIODIC SERVICING

QUICK FAULT FINDING

PERIODICAL REPLACING PARTS

STABILITY OF FORKLIFT TRUCK

SPECIFICATIONS

COLD STORAGE TYPE FORKLIFT TRUCK

SIDESHIFT ATTACHMENT

Included

Service Manual

2Operate and Maintenance manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары