$49.99

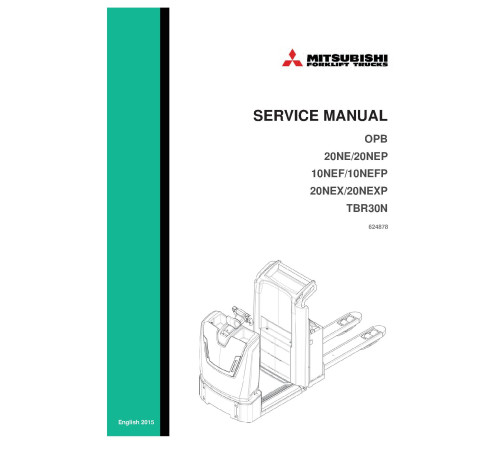

Service Manual

3Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

2Aditional Service Information

4Illustrated factory set of Service Manuals for Mitsubishi Order Pickers Models OPB20NE, OPB20NEP, OPB10NEF, OPB10NEFP, OPB20NEX, OPB20NEXP and TBR30N.

This manuals will assist you in diagnosing, analyses, testing, repair, operating, maintaining, troubleshooting, and other for your order picker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

OPB20NE

OPB20NEP

OPB10NEF

OPB10NEFP

OPB20NEX

OPB20NEXP

TBR30N

The manual comprises 12 documents, including three Service Manuals, the Operate and Maintenance manual, two Wiring Diagrams, two Hydraulic Circuit Diagrams, and four Aditional Service Informations

1. Service Manual (SM-624878_0115)

Format: PDF, 352 pages

Language: English

Table of Contents:

Foreword

How to read this manual

Safety-related signs

Symbols and abbreviations

Units

Safety instructions

Service area safety

Personal safety

Work safety

General information

Truck models covered by this manual

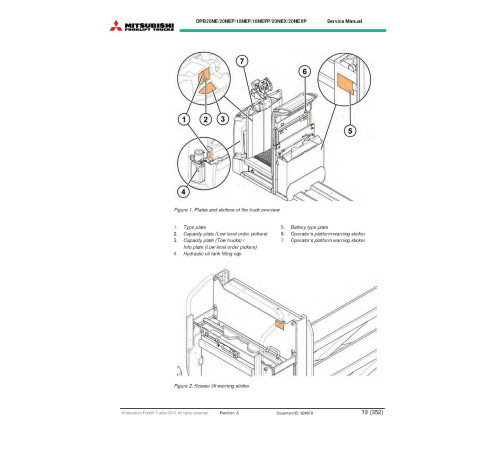

Identification plates on the truck

Overview of the truck

Mechanical maintenance

Lifting points

Transportation

Order spare parts

Truck covers

Transmission gear

Slewing bearing

Traction wheel

Load wheels

Lifting system and fork carriage

Castor wheels

Drive unit

Steering wheel

? steering

Simplex mast unit

Operator presence sensing platform

Lifting platform

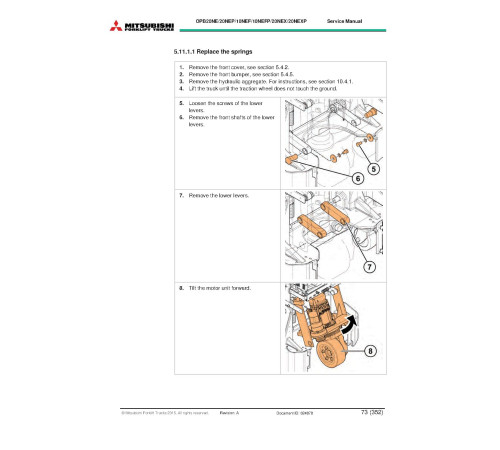

Scissor lift

Trailer towing unit

Electrical operation

Schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

AC motor operation

Battery maintenance

Safety precautions concerning the handling of lead-acid batteries

Battery maintenance

Charge the battery

Measure the specific gravity of the battery

Replace the battery

Electric system maintenance

Control panel

Electric panel

Truck connector

Motor compartment

Sensors

Lifting platform pedal

Horn

Electric system adjustments and measurements

Adjusting the electrical steering

Insulation resistance test

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Hydraulic aggregate

Replace the hydraulic cylinder

Hydraulic system withthe lifting platform

Hydraulic system with the simplex mast

Digital console

Connect the digital console to the truck

Select the controller

Adjust the parameters with the digital console

Parameter descriptions

Traction controller

Pump controller

Steering controller

Alarm codes

Traction controller

Pump controller

Steering controller

Service data

Special tightening torques

Tightening torques for standard bolts and nuts

Maintenance check list

Lubrication

Special tools

Options

Accessory rack

Visual Assistant

Equipment pocket

Picking plane

DC-DC converter

Folding seat

Padded backrest

Battery connector + cables

Charger connector

Quick battery replacement

Hot storage modification

Cold storage modification

Warning light

Drive alarm

Abbot2

Load support

Rubber bumper

Battery cover plate

Pallet entry / exit rollers

High performance pack

Pedestrian control buttons

Technical specification

Index

APPENDIX A: Stickers.

2. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

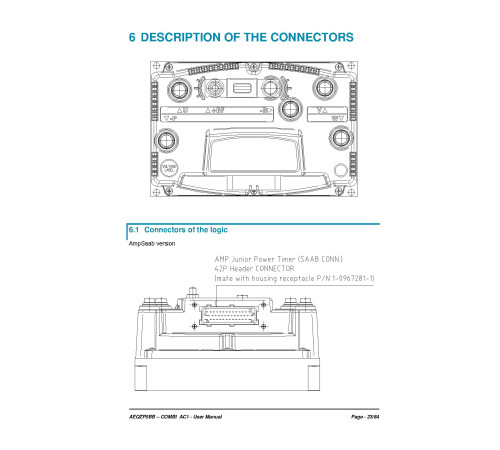

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

3. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

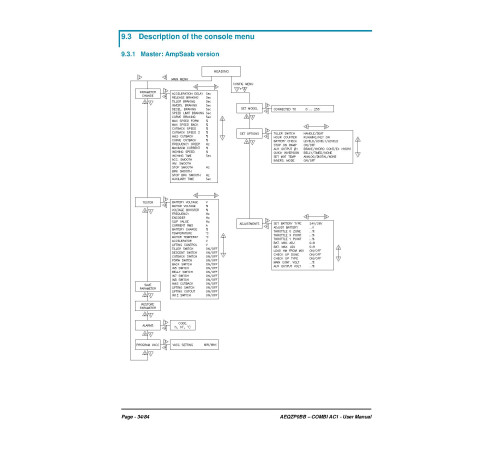

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

4. Operate and Maintenance manual (OMM-WWHOU-00012_0107)

Format: PDF, 45 pages

Language: English

Table of Contents:

Truck

Safety instructions

Operating environment

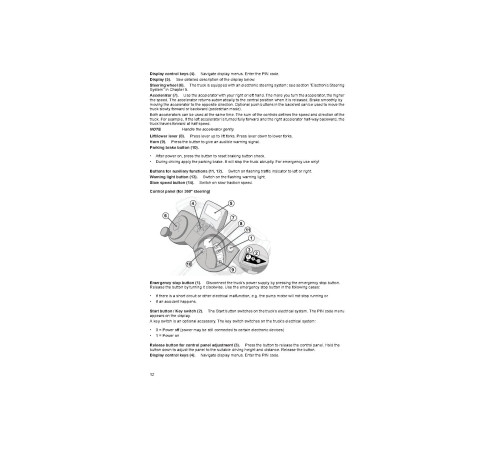

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

5. Wiring Diagram (EL-TS1320212_OPB20NE)

Format: PDF, 12 pages

Language: English

Table of Contents:

3-7022: OPB20NE,TBR30N

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 180º STEERING

5: DRIVE CIRCUIT 360º STEERING

6: STEERING CIRCUIT

7: CAN-BUS AND DISPLAY

8: OUTPUTS

9: COLD STORAGE, AUX. DEVICES

10: PEDESTRIAN CONTROL

11: ABBOT 2

12: TOW TRACTOR BRAKES RL497336

6. Wiring Diagram (EL-TS1320000_B)

Format: PDF, 13 pages

Language: English

Table of Contents:

3-7117: OPB20NEP,OPB20NEX(P), OPB10NEF(P)

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 2

5: DRIVE CIRCUIT 180º STEERING

6: STEERING CIRCUIT

7: CAN-BUS AND DISPLAY

8: OUTPUTS

9: COLD STORAGE, AUX. DEVICES

10: PEDESTRIAN CONTROL

11: ABBOT 2

12: RISING PLATFOTM

13: RISING PLATFOTM 2

7. Hydraulic Circuit Diagram (HY-TH90)

Format: PDF, 1 page

Language: English

8. Hydraulic Circuit Diagram (HY-TH78-0409)

Format: PDF, 1 page

Language: English

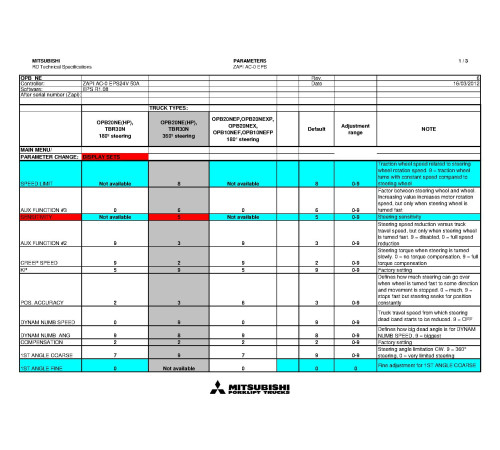

9. Aditional Service Information: Parameters-Traction Controller (PA-OPB20NEP_OPB20NEX_OPB10NEF_PUMP_RO0.01)

Format: PDF, 3 pages

Language: English

10. Aditional Service Information: Parameters-Traction Controller (PA-OPB20NE_TBR30N_TracRO0.36)

Format: PDF, 13 pages

Language: English

11. Aditional Service Information: Patameters - Pump Controller (PA-OPB20NE_TBR30N_PumpRO0.30)

Format: PDF, 4 pages

Language: English

Table of Contents:

PARAMETERS

TESTER FUNCTIONS

12. Aditional Service Information: Parameters EPS (PA-EPS_R1.08-160312)

Format: PDF, 3 pages

Language: English

This manuals will assist you in diagnosing, analyses, testing, repair, operating, maintaining, troubleshooting, and other for your order picker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

OPB20NE

OPB20NEP

OPB10NEF

OPB10NEFP

OPB20NEX

OPB20NEXP

TBR30N

The manual comprises 12 documents, including three Service Manuals, the Operate and Maintenance manual, two Wiring Diagrams, two Hydraulic Circuit Diagrams, and four Aditional Service Informations

1. Service Manual (SM-624878_0115)

Format: PDF, 352 pages

Language: English

Table of Contents:

Foreword

How to read this manual

Safety-related signs

Symbols and abbreviations

Units

Safety instructions

Service area safety

Personal safety

Work safety

General information

Truck models covered by this manual

Identification plates on the truck

Overview of the truck

Mechanical maintenance

Lifting points

Transportation

Order spare parts

Truck covers

Transmission gear

Slewing bearing

Traction wheel

Load wheels

Lifting system and fork carriage

Castor wheels

Drive unit

Steering wheel

? steering

Simplex mast unit

Operator presence sensing platform

Lifting platform

Scissor lift

Trailer towing unit

Electrical operation

Schematic diagram

Power source

Safety circuit (emergency stop button)

Key switch

Traction

AC motor operation

Battery maintenance

Safety precautions concerning the handling of lead-acid batteries

Battery maintenance

Charge the battery

Measure the specific gravity of the battery

Replace the battery

Electric system maintenance

Control panel

Electric panel

Truck connector

Motor compartment

Sensors

Lifting platform pedal

Horn

Electric system adjustments and measurements

Adjusting the electrical steering

Insulation resistance test

Hydraulic operation

Hydraulic symbols

Hydraulic oil recommendations

Maintenance points of the hydraulic system

Hydraulic aggregate

Replace the hydraulic cylinder

Hydraulic system withthe lifting platform

Hydraulic system with the simplex mast

Digital console

Connect the digital console to the truck

Select the controller

Adjust the parameters with the digital console

Parameter descriptions

Traction controller

Pump controller

Steering controller

Alarm codes

Traction controller

Pump controller

Steering controller

Service data

Special tightening torques

Tightening torques for standard bolts and nuts

Maintenance check list

Lubrication

Special tools

Options

Accessory rack

Visual Assistant

Equipment pocket

Picking plane

DC-DC converter

Folding seat

Padded backrest

Battery connector + cables

Charger connector

Quick battery replacement

Hot storage modification

Cold storage modification

Warning light

Drive alarm

Abbot2

Load support

Rubber bumper

Battery cover plate

Pallet entry / exit rollers

High performance pack

Pedestrian control buttons

Technical specification

Index

APPENDIX A: Stickers.

2. Service Manual: ZAPI EPS-AC0 (Zapi_EPS-AC0)

Format: PDF, 95 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagram

Electrical specifications

Mechanical specifications

FUNCTIONS OF THE EPS-AC0

Manual Mode Steering

Automatic Centering

Operational features

Diagnosis

SYSTEM COMPONENTS

Steering Motor

Gear Box and total reduction ratio

Eps-ac0 controller

Sensor in the steering handle

Feedback sensors

AUTC MODE

CONNECTING DIAGRAMS

Power Connecting Diagram

EPS-AC0 Stepper Motor diagram

EPS-AC0 Twin pot diagram

CONNECTIONS: SUGGESTIONS AND CAUTIONS

Stepper Motor connections

Twin pot connections

Encoder connections

Feedback pot connections

Digital Inputs connections

Safety contacts

Motor thermal sensor connections

INSTALLATION: SUGGESTIONS AND CAUTIONS

Thermal consideration

General suggestion

Connection cables

Fuses

Contactors

Installation of a CAN Communication System

Wiring: I/O connections

Safety features

EMC

Fighting the dither

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

INSTALLATION PROCEDURE

Twin Pot with Encoder and Feedback pot: one shot installation procedure .4

Twin Pot with Encoder, Straight Ahead Switch and Feedback pot: one shot installa

procedure

Stepper Motor with Encoder and Feedback pot: one shot installation procedure

Stepper Motor with Encoder and Toggle Switch(es): one shot installation procedure

SETTING THE EPS-AC0

Complete set-up description

Quick set-up

PROGRAMMAING & ADJUSTMENTS USING DIGITAL CONSOLE.5

Adjustments via console

Description of console (hand set) & connection

Description of standard console menu

Function configuration

OTHER FUNCTIONS

Acquiring the Motor resistance

Alignment at the rest position

Straight ahead steering numbness

Special Debugging and Troubleshooting system

EPS-AC0 ALARMS LIST

Main menu “ALARMS” list

CAN BUS “ALARMS” List

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED

Testing the faulty detection circuitry .

3. Service Manual: ZAPI COMBI AC1 Controller (ZAPI_COMBI_AC1)

Format: PDF, 84 pages

Language: English

Table of Contents:

INTRODUCTION

SPECIFICATION

Technical specifications

Block diagrams

SPECIFICATION FOR THE INPUT DEVICES FILLING UP THE INSTALLATION KIT

Digital inputs

Analog unit

Other analog control unit

Analog motor thermal sensor input

Speed feedback

INSTALLATION HINTS

Material overview

Installation of the hardware

Protection and safety features

EMC

Various suggestions

OPERATIONAL FEATURES

Diagnosis

DESCRIPTION OF THE CONNECTORS

Connectors of the logic

Description of power connections

DRAWINGS

Mechanical drawing

Connection drawing

ONE SHOT INSTALLATION PROCEDURE

Sequence for Ac Inverter traction setting

PROGRAMMING & ADJUSTMENTS USING DIGITAL CONSOLE

Adjustments via console

Description of console (hand set) & connection

Description of the console menu

Function configuration (MASTER)

Function configuration (SLAVE)

OTHER FUNCTIONS

Description of console “SAVE” function

Description of console “RESTORE” function

Description of console “PROGRAM VACC” function

Description of the throttle regulation

Description of the battery charge detection setting

COMBI AC1 ALARMS LIST

Faults diagnostic system

Master microcontroller alarms overview

Analysis and troubleshooting of Master microcontroller alarms

Master warnings overview

Analysis and troubleshooting of Master warnings

Slave alarms overview

Analysis and troubleshooting of Slave alarms

Slave warnings overview

Analysis and troubleshooting of Slave warnings

RECOMMENDED SPARE PARTS

PERIODIC MAINTENANCE TO BE REPEATED AT TIMES INDICATED.

4. Operate and Maintenance manual (OMM-WWHOU-00012_0107)

Format: PDF, 45 pages

Language: English

Table of Contents:

Truck

Safety instructions

Operating environment

Operating devices

Driving instructions

Load handling

Batteries

Maintenance

Service

Transportation and storage

Troubleshooting

Technical specifications .

5. Wiring Diagram (EL-TS1320212_OPB20NE)

Format: PDF, 12 pages

Language: English

Table of Contents:

3-7022: OPB20NE,TBR30N

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 180º STEERING

5: DRIVE CIRCUIT 360º STEERING

6: STEERING CIRCUIT

7: CAN-BUS AND DISPLAY

8: OUTPUTS

9: COLD STORAGE, AUX. DEVICES

10: PEDESTRIAN CONTROL

11: ABBOT 2

12: TOW TRACTOR BRAKES RL497336

6. Wiring Diagram (EL-TS1320000_B)

Format: PDF, 13 pages

Language: English

Table of Contents:

3-7117: OPB20NEP,OPB20NEX(P), OPB10NEF(P)

1: POWER SUPPLY 24 V

2: MAINCIRCUITS

3: DRIVE CIRCUIT

4: DRIVE CIRCUIT 2

5: DRIVE CIRCUIT 180º STEERING

6: STEERING CIRCUIT

7: CAN-BUS AND DISPLAY

8: OUTPUTS

9: COLD STORAGE, AUX. DEVICES

10: PEDESTRIAN CONTROL

11: ABBOT 2

12: RISING PLATFOTM

13: RISING PLATFOTM 2

7. Hydraulic Circuit Diagram (HY-TH90)

Format: PDF, 1 page

Language: English

8. Hydraulic Circuit Diagram (HY-TH78-0409)

Format: PDF, 1 page

Language: English

9. Aditional Service Information: Parameters-Traction Controller (PA-OPB20NEP_OPB20NEX_OPB10NEF_PUMP_RO0.01)

Format: PDF, 3 pages

Language: English

10. Aditional Service Information: Parameters-Traction Controller (PA-OPB20NE_TBR30N_TracRO0.36)

Format: PDF, 13 pages

Language: English

11. Aditional Service Information: Patameters - Pump Controller (PA-OPB20NE_TBR30N_PumpRO0.30)

Format: PDF, 4 pages

Language: English

Table of Contents:

PARAMETERS

TESTER FUNCTIONS

12. Aditional Service Information: Parameters EPS (PA-EPS_R1.08-160312)

Format: PDF, 3 pages

Language: English

Included

Service Manual

3Operate and Maintenance manual

1Wiring Diagram

2Hydraulic Circuit Diagram

2Aditional Service Information

4Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары