Illustrated factory set of Service Manuals for Mitsubishi Electric Forklift Trucks Models FB13TCA (215AF0001-up), FB15TCA (216AF0001-up), FB18TCA (216AF0001-up) and FB20TCA (288AD0001-up).

This manuals will assist you in diagnosing, analyses, testing, and repair for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB13TCA (215AF0001-up)

FB15TCA (216AF0001-up)

FB18TCA (216AF0001-up)

FB20TCA (288AD0001-up)

The manual comprises two Service Manuals

1. Service Manual: Controller (SM-99N19-52100_Controller_E08)

Format: PDF, 108 pages

Language: English

Table of Contents:

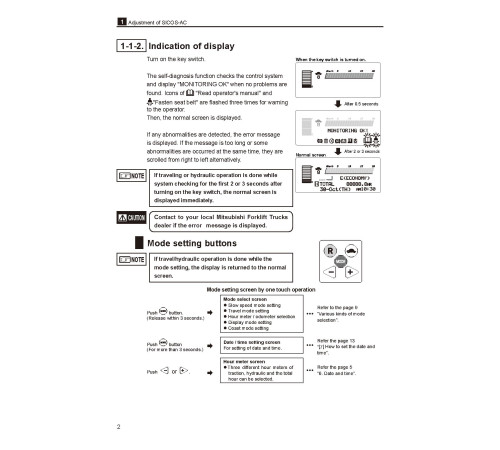

Adjustment of SICOS-AC

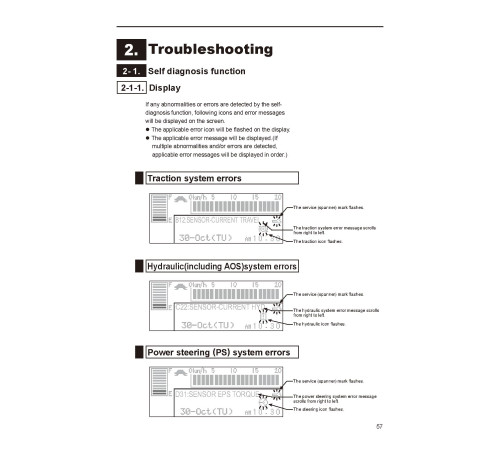

Troubleshooting

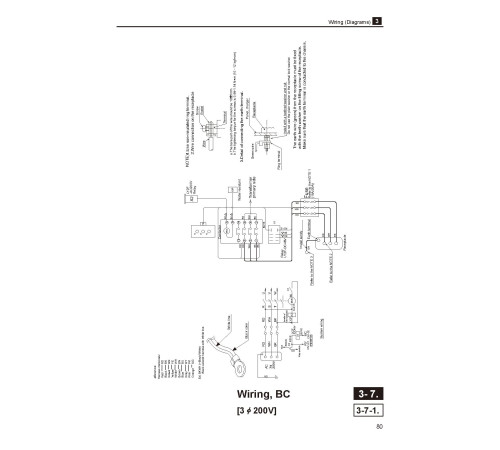

Wiring (Diagrams)

Reference

2. Service Manual: Chassis, Mast (SM-99N19-50100_E08)

Format: PDF, 189 pages

Language: English

Table of Contents:

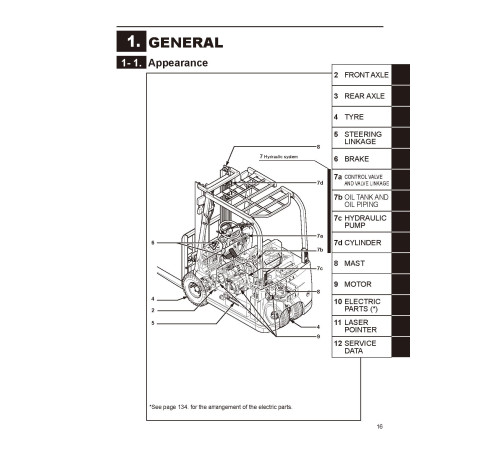

1. GENERAL

1-1. Appearance

1-2. Specifications

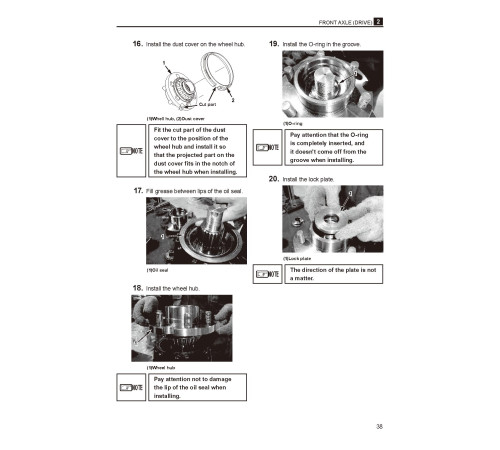

2. FRONT AXLE (DRIVE)

2-1. Disassembly and reassembly

2-1-1. Front axle - removal

2-1-2. Disassembly transfer ASS`Y

2-1-3. Reassembly the transfer ASS`Y

3. REAR AXLE (STEERING)

3-1. Disassembly and reassembly

3-1-1. Rear axle - removal and installation

3-1-2. Rear axle - disassembly and reassembly

3-2. Inspection and adjustment

3-2-1. Angle sensor comp. - adjustment

3-2-2. EPS torque sensor - adjustment

3-3. Troubleshooting

3-3-1. Rear axle - troubleshooting

4. TYRE

4-1. Front tyre

4-1-1. Front tyre - disassembly and reassembly

4-1-2. Tyre size (front)

4-2. Rear tyre

4-2-1. Rear tyre - disassembly and reassembly

4-2-2. Tyre size (rear)

4-3. Inspection and adjustment

4-3-1. Bolt nut - inspection

4-3-2. Air pressure - inspection

4-3-3. Tyre - visual inspection and replacement

4-4. Troubleshooting

4-4-1. Tyre - troubleshooting

5. STEERING LINKAGE

5-1. Disassembly and reassembly

5-1-1. Steering linkage- disassembly and reassembly

5-2. Inspection and adjustment

5-2-1. Joint - inspection and replacement

5-2-2. Knob - inspection and replacement

5-2-3. Steering wheel - inspection and replacement

5-2-4. Chain comp., roller - adjustment

6. BRAKE

6-1. Foot brake

6-1-1. Foot brake - disassembly and reassembly

6-2. Parking brake

6-2-1. Parking brake - disassembly and reassembly

6-3. Inspection and adjustment

6-3-1. Brake pedal - adjustment

6-3-2. Brake pedal - inspection

6-3-3. Microswitch of parking brake lever - adjustment

6-3-4. Parking lever - inspection and adjustment

6-3-5. Master cylinder ASS`Y- inspection and replacement

6-3-6. Master cylinder air bleeding

6-4. Troubleshooting

6-4-1. Brake - troubleshooting

7. HYDRAULIC SYSTEM

7-1. Oil piping circuit

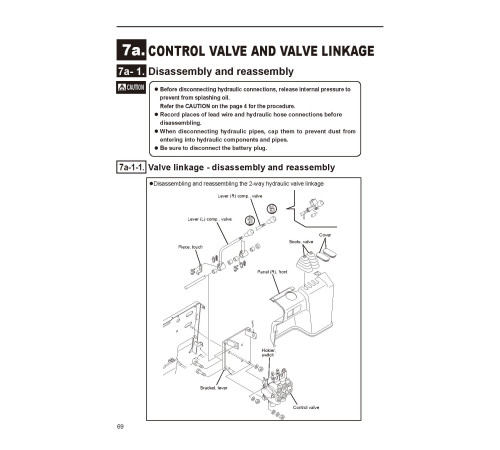

7a CONROL VALVE AND VALVE LINKAGE

7a-1. Disassembly and reassembly

7a-1-1. Valve linkage - disassembly and reassembly

7a-1-2. Control valve

7a-2. Inspection and adjustment

7a-2-1. Relief pressure - adjustment

7a-2-2. Microswitch - adjustment

7a-3. Trouble shooting

7a-3-1. Control valve - troubleshooting

7b. OIL TANK AND OIL PIPING

7b-1. Disassembly and reassembly

7b-1-1. Oil tank - disassembly and reassembly

7b-1-2. Oil piping replacement - precautions

7b-2. Inspection and adjustment

7b-2-1. Oil - inspection

7b-2-2. Recommended oil and quantity for hydraulic circuit (except brake and gear oil)

7b-2-3. Oil tank and filters - cleaning and check

7b-3. Troubleshooting

7b-3-1. Oil tank - troubleshooting

7c. HYDRAULICPUMP

7c-1. Removal and installation

7c-1-1. Hydraulic pump -removal and installation

7d. CYLINDER

7d-1. Disassembly and reassembly

7d-1-1. Lift cylinder - removal : 2SP - mast (2 - stage simplex)

7d-1-2. Lift cylinder - removal : 2FP-mast (2-stage duplex), 3FP-mast (3-stage triplex

7d-1-3. Tilt cylinder - removal

7d-1-4. Lift cylinder - installation and adjustment

7d-1-5. Tilt cylinder - installation

7d-1-6. Lift cylinder - disassembly and reassembly

7d-1-7. Tilt cylinder - disassembly and reassembly

7d-2. Inspection and adjustment

7d-2-1. Cylinder comp. - inspection

7d-2-2. Piston rod - inspection

7d-2-3. Drift for lift and tilt - inspection

7d-3. Variation of the tilt cylinder

7d-3-1. Tilt angle by masts

7d-4. Troubleshooting

7d-4-1. Cylinder - troubleshooting

8. MAST

8-1. Disassembly and reassembly

8-1-1. Lift bracket ASS`Y- removal

8-1-2. Mast ASS`Y - removal

8-1-3. Mast - disassembly and reassembly

8-2. Inspection and adjustment

8-2-1. Mast, lift bracket and roller shaft - inspection

8-2-2. Back shoe - inspection

8-2-3. Lift chain - inspection and replacement

8-2-4. Chain bolt - inspection

8-2-5. Chain wheel - inspection

8-2-6. Roller - inspection and replacement

8-2-7. Fork - inspection and replacement

8-2-8. Lift chain - inspection and adjustment

8-2-9. Mast lean- adjustment

8-3. Troubleshooting

8-3-1. Mast Lift bracket Fork - troubleshooting

9. MOTOR

9-1. Disassembly and reassembly

9-1-1. Traction motor - removal and installation

9-1-2. Hydraulic motor - removal and installation

9-1-3. EPS motor - removal and installation

9-1-4. Traction motor - disassembly and reassembly

9-1-5. Hydraulic motor - disassembly and reassembly

9-1-6. EPS motor - disassembly and reassembly

9-2. Inspection and adjustment

9-2-1. Rotor comp. (Traction/hydraulic motor) - inspection and replacement

9-2-2. Armature comp. (EPS motor) - inspection and replacement

9-2-3. Brush, brush holder and spring (EPS motor) - inspection and replacement

9-2-4. Motor ASS`Y (Traction/Hydraulic motor) - inspection

9-2-5. Motor ASS`Y (EPS motor) - inspection

9-2-6. Oil seal and permanent magnet (EPS motor) inspection and replacement

9-2-7. Motor - specification

9-3. Troubleshooting

9-3-1. Motor - troubleshooting

10. ELECTRIC PARTS

10-1. Location and name

10a. CONTROL UNIT

10a-1. Location and name

10a-2. Disassembly and reassembly

10a-2-1. Control unit - removal and installation

10a-2-2. EPS controller - removal and installation

10a-2-3. Control unit - disassembly and reassembly

10a-3. Check and replacement

10a-3-1. Main connector - inspection and replacement

10a-3-2. Module, FET - inspection and replacement

10a-3-3. Capacitor - check and replacement

10b. ACCELERATOR

10b-1. Disassembly and reassembly

10b-1-1. Accelerator linkage - removal and installation

10b-2. Inspection and adjustment

10b-2-1. Potentiometer - adjustment

10b-2-2. Accelerator linkage - adjustment

10c. DISPLAY PANEL AND DIRECTIONAL SWITCH

10c-1. Disassembly and reassembly

10c-1-1. Display panel - disassembly and reassembly

10c-1-2. Directional switch - disassembly and reassembly

10d. BATTERY

10d-1. Removal and installation

10d-1-1. Battery - removal and installation

10d-2. Inspection and adjustment

10d-2-1. Battery - inspection and adjustment

10d-2-2. Battery - Cleaning

10e. CHARGER (BUILT - IN)

10e-1. Disassembly and reassembly

10e-1-1. Charger ASS`Y - disassembly and reassembly

10e-1-2. Transformer - disassembly and reassembly

10e-1-3. Built-in charger - specification

10e-2. Inspection and replacement

10e-2-1. Magnetic contactor - inspection

10e-2-2. Plug comp. and receptacle - inspection and replacement

10e-2-3. Fuse and fuse base - inspection

10e-2-4. Transformer - inspection

10e-2-5. Diode - inspection

10e-3. Inspection After Assembly

10e-3-1. Timer - inspection

10e-4. Charging procedure

10e-4-1. Automatic charge (Daily charge)

10e-4-2. Balancing charge

10e-4-3. Inspection after charging

10e-5. Voltage tap

10e-5-1. Power supply voltage - check

10e-5-2. Voltage tap - selection

10e-5-3. Voltage tap - changing

10e-5-4. Fuse (three-phase voltage) - replacement

11. LASER POINTER (OPTION)

11-1. Adjustment

11-1-1. Fork level - adjustment

11-1-2. Laser optical axis - adjustment

12. SERVICE DATA

12-1. Standard work hours

This manuals will assist you in diagnosing, analyses, testing, and repair for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FB13TCA (215AF0001-up)

FB15TCA (216AF0001-up)

FB18TCA (216AF0001-up)

FB20TCA (288AD0001-up)

The manual comprises two Service Manuals

1. Service Manual: Controller (SM-99N19-52100_Controller_E08)

Format: PDF, 108 pages

Language: English

Table of Contents:

Adjustment of SICOS-AC

Troubleshooting

Wiring (Diagrams)

Reference

2. Service Manual: Chassis, Mast (SM-99N19-50100_E08)

Format: PDF, 189 pages

Language: English

Table of Contents:

1. GENERAL

1-1. Appearance

1-2. Specifications

2. FRONT AXLE (DRIVE)

2-1. Disassembly and reassembly

2-1-1. Front axle - removal

2-1-2. Disassembly transfer ASS`Y

2-1-3. Reassembly the transfer ASS`Y

3. REAR AXLE (STEERING)

3-1. Disassembly and reassembly

3-1-1. Rear axle - removal and installation

3-1-2. Rear axle - disassembly and reassembly

3-2. Inspection and adjustment

3-2-1. Angle sensor comp. - adjustment

3-2-2. EPS torque sensor - adjustment

3-3. Troubleshooting

3-3-1. Rear axle - troubleshooting

4. TYRE

4-1. Front tyre

4-1-1. Front tyre - disassembly and reassembly

4-1-2. Tyre size (front)

4-2. Rear tyre

4-2-1. Rear tyre - disassembly and reassembly

4-2-2. Tyre size (rear)

4-3. Inspection and adjustment

4-3-1. Bolt nut - inspection

4-3-2. Air pressure - inspection

4-3-3. Tyre - visual inspection and replacement

4-4. Troubleshooting

4-4-1. Tyre - troubleshooting

5. STEERING LINKAGE

5-1. Disassembly and reassembly

5-1-1. Steering linkage- disassembly and reassembly

5-2. Inspection and adjustment

5-2-1. Joint - inspection and replacement

5-2-2. Knob - inspection and replacement

5-2-3. Steering wheel - inspection and replacement

5-2-4. Chain comp., roller - adjustment

6. BRAKE

6-1. Foot brake

6-1-1. Foot brake - disassembly and reassembly

6-2. Parking brake

6-2-1. Parking brake - disassembly and reassembly

6-3. Inspection and adjustment

6-3-1. Brake pedal - adjustment

6-3-2. Brake pedal - inspection

6-3-3. Microswitch of parking brake lever - adjustment

6-3-4. Parking lever - inspection and adjustment

6-3-5. Master cylinder ASS`Y- inspection and replacement

6-3-6. Master cylinder air bleeding

6-4. Troubleshooting

6-4-1. Brake - troubleshooting

7. HYDRAULIC SYSTEM

7-1. Oil piping circuit

7a CONROL VALVE AND VALVE LINKAGE

7a-1. Disassembly and reassembly

7a-1-1. Valve linkage - disassembly and reassembly

7a-1-2. Control valve

7a-2. Inspection and adjustment

7a-2-1. Relief pressure - adjustment

7a-2-2. Microswitch - adjustment

7a-3. Trouble shooting

7a-3-1. Control valve - troubleshooting

7b. OIL TANK AND OIL PIPING

7b-1. Disassembly and reassembly

7b-1-1. Oil tank - disassembly and reassembly

7b-1-2. Oil piping replacement - precautions

7b-2. Inspection and adjustment

7b-2-1. Oil - inspection

7b-2-2. Recommended oil and quantity for hydraulic circuit (except brake and gear oil)

7b-2-3. Oil tank and filters - cleaning and check

7b-3. Troubleshooting

7b-3-1. Oil tank - troubleshooting

7c. HYDRAULICPUMP

7c-1. Removal and installation

7c-1-1. Hydraulic pump -removal and installation

7d. CYLINDER

7d-1. Disassembly and reassembly

7d-1-1. Lift cylinder - removal : 2SP - mast (2 - stage simplex)

7d-1-2. Lift cylinder - removal : 2FP-mast (2-stage duplex), 3FP-mast (3-stage triplex

7d-1-3. Tilt cylinder - removal

7d-1-4. Lift cylinder - installation and adjustment

7d-1-5. Tilt cylinder - installation

7d-1-6. Lift cylinder - disassembly and reassembly

7d-1-7. Tilt cylinder - disassembly and reassembly

7d-2. Inspection and adjustment

7d-2-1. Cylinder comp. - inspection

7d-2-2. Piston rod - inspection

7d-2-3. Drift for lift and tilt - inspection

7d-3. Variation of the tilt cylinder

7d-3-1. Tilt angle by masts

7d-4. Troubleshooting

7d-4-1. Cylinder - troubleshooting

8. MAST

8-1. Disassembly and reassembly

8-1-1. Lift bracket ASS`Y- removal

8-1-2. Mast ASS`Y - removal

8-1-3. Mast - disassembly and reassembly

8-2. Inspection and adjustment

8-2-1. Mast, lift bracket and roller shaft - inspection

8-2-2. Back shoe - inspection

8-2-3. Lift chain - inspection and replacement

8-2-4. Chain bolt - inspection

8-2-5. Chain wheel - inspection

8-2-6. Roller - inspection and replacement

8-2-7. Fork - inspection and replacement

8-2-8. Lift chain - inspection and adjustment

8-2-9. Mast lean- adjustment

8-3. Troubleshooting

8-3-1. Mast Lift bracket Fork - troubleshooting

9. MOTOR

9-1. Disassembly and reassembly

9-1-1. Traction motor - removal and installation

9-1-2. Hydraulic motor - removal and installation

9-1-3. EPS motor - removal and installation

9-1-4. Traction motor - disassembly and reassembly

9-1-5. Hydraulic motor - disassembly and reassembly

9-1-6. EPS motor - disassembly and reassembly

9-2. Inspection and adjustment

9-2-1. Rotor comp. (Traction/hydraulic motor) - inspection and replacement

9-2-2. Armature comp. (EPS motor) - inspection and replacement

9-2-3. Brush, brush holder and spring (EPS motor) - inspection and replacement

9-2-4. Motor ASS`Y (Traction/Hydraulic motor) - inspection

9-2-5. Motor ASS`Y (EPS motor) - inspection

9-2-6. Oil seal and permanent magnet (EPS motor) inspection and replacement

9-2-7. Motor - specification

9-3. Troubleshooting

9-3-1. Motor - troubleshooting

10. ELECTRIC PARTS

10-1. Location and name

10a. CONTROL UNIT

10a-1. Location and name

10a-2. Disassembly and reassembly

10a-2-1. Control unit - removal and installation

10a-2-2. EPS controller - removal and installation

10a-2-3. Control unit - disassembly and reassembly

10a-3. Check and replacement

10a-3-1. Main connector - inspection and replacement

10a-3-2. Module, FET - inspection and replacement

10a-3-3. Capacitor - check and replacement

10b. ACCELERATOR

10b-1. Disassembly and reassembly

10b-1-1. Accelerator linkage - removal and installation

10b-2. Inspection and adjustment

10b-2-1. Potentiometer - adjustment

10b-2-2. Accelerator linkage - adjustment

10c. DISPLAY PANEL AND DIRECTIONAL SWITCH

10c-1. Disassembly and reassembly

10c-1-1. Display panel - disassembly and reassembly

10c-1-2. Directional switch - disassembly and reassembly

10d. BATTERY

10d-1. Removal and installation

10d-1-1. Battery - removal and installation

10d-2. Inspection and adjustment

10d-2-1. Battery - inspection and adjustment

10d-2-2. Battery - Cleaning

10e. CHARGER (BUILT - IN)

10e-1. Disassembly and reassembly

10e-1-1. Charger ASS`Y - disassembly and reassembly

10e-1-2. Transformer - disassembly and reassembly

10e-1-3. Built-in charger - specification

10e-2. Inspection and replacement

10e-2-1. Magnetic contactor - inspection

10e-2-2. Plug comp. and receptacle - inspection and replacement

10e-2-3. Fuse and fuse base - inspection

10e-2-4. Transformer - inspection

10e-2-5. Diode - inspection

10e-3. Inspection After Assembly

10e-3-1. Timer - inspection

10e-4. Charging procedure

10e-4-1. Automatic charge (Daily charge)

10e-4-2. Balancing charge

10e-4-3. Inspection after charging

10e-5. Voltage tap

10e-5-1. Power supply voltage - check

10e-5-2. Voltage tap - selection

10e-5-3. Voltage tap - changing

10e-5-4. Fuse (three-phase voltage) - replacement

11. LASER POINTER (OPTION)

11-1. Adjustment

11-1-1. Fork level - adjustment

11-1-2. Laser optical axis - adjustment

12. SERVICE DATA

12-1. Standard work hours

Included

Service Manual

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары