Illustrated factory Repair Manual for Toyota Electric Forklift Trucks Models 8FBMT40, 8FBMT45 and 8FBMT50.

This manual will assist you in assembling, disassembling, and repairing for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

8FBMT40

8FBMT45

8FBMT50

Format: PDF, 702 pages

Language: English

Table of Contents:

GENERAL

VEHICLE EXTERIOR VIEW

VEHICLE MODELS

CHASSIS NUMBER

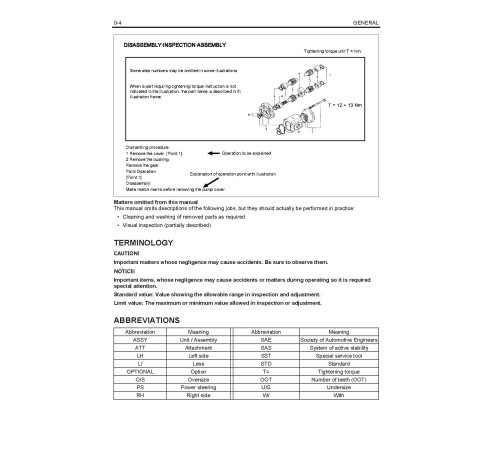

HOW TO USE THIS MANUAL

OPERATING TIPS

LIST OF SUSPENSION ROPE ANGLES

SAFETY LOAD FOR EACH SUSPENSION ROPE ANGLE

COMPONENT WEIGHTS

TOWING THE TRUCK

ELECTRICAL COMPONENTS INSPECTION

NOTES ON SAS

TIGHTENING TORQUE TABLE

TABLE OF LUBRICANTS AND FLUIDS

PERIODIC MAINTENANCE

SAS Periodic maintenance

BATTERY

BATTERY COMPARTMENT AND REQUIRED WEIGHT

STANDARD SERVICE VALUES

MULTI-DISPLAY FUNCTIONS

STATE OF BATTERY CHARGE INDICATOR

PROCEDURE SET TEMPERATURE SENSOR BATTERY

BATTERY MANAGEMENT PARAMETERS

TABLE OF BDI MAX, BDI MIN, RESET VOLT VALUES

BATTERY INDICATOR TROUBLESHOOTING

TROUBLESHOOTING

BATTERY UNIT

INSPECTION

STATE OF BATTERY CHARGE

BATTERY CAPACITY

GEL BATTERIES

REPLACING BATTERY PLUG TERMINALS

CONTROL SYSTEM

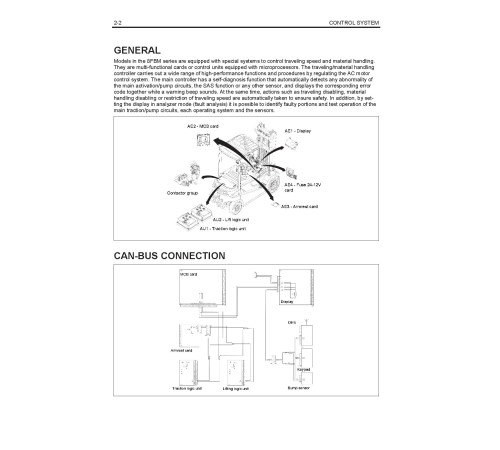

GENERAL

CAN-BUS CONNECTION

REAR COMPARTMENT FUSES

FUSES UNDER DASHBOARD

CONTACTORS

DC/DC CONVERTERS

LOGIC UNITS

CONTACTOR GROUP

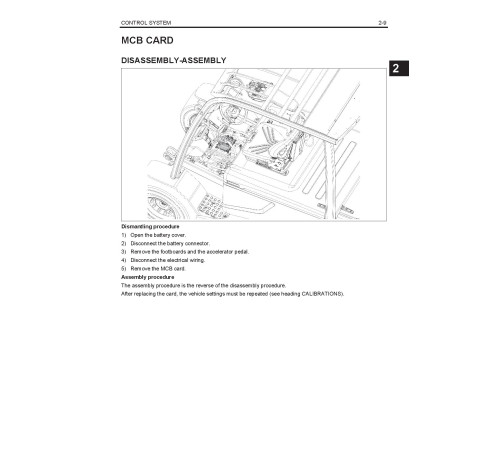

MCB CARD

MULTI-DISPLAY FUNCTIONS

24-12 V FUSE CARD

ARMREST CARD

ARMREST CARD POTENTIOMETERS

ACCELERATOR POTENTIOMETER

STEERING POTENTIOMETER

[Point 1]

[Point 2]

TILT ANGLE POTENTIOMETER

[Point 1]

MAST PRESSURE SENSOR

MAST HEIGHT SWITCH

YAW RATE SENSOR

CALIBRATIONS

MULTI-FUNCTION DISPLAY

GENERAL

MENU MAP

OPERATOR MENU

ADMINISTRATOR MENU

ADMINISTRATOR menu screen (with vehicle startup using key)

ADMINISTRATOR menu screen (with vehicle startup using pin code via keypad)

MASK MENU

ANALYZER

TUNING

OPTION SET

MATCHING

OTHERS MENU

TROUBLESHOOTING

CONNECTOR CHECK

WIRE HARNESS AND CONNECTORS INSPECTION PROCEDURE

INSULATION CHECK PROCEDURE

MOTOR WINDING CHECK PROCEDURE

TEMPERATURE SENSOR CHECK PROCEDURE

CAN-BUS CHECK PROCEDURE

DIAGNOSTIC CODES LIST

WHEN AN ERROR CODE IS DISPLAYED

MOTOR

SENSOR

Point Operations

DISASSEMBLY-ASSEMBLY

PUMP MOTOR:

Point Operations

DRIVE UNIT and FRONT AXLE

GENERAL

COMPONENTS - STANDARD VERSION

COMPONENTS - NEGATIVE BRAKE VERSION

FRONT AXLE ASSEMBLY

Point Operations

MAINTENANCE

REAR AXLE

REAR AXLE ASSEMBLY

REAR AXLE

Point Operations

REAR AXLE HUB - CAST ARTICULATED JOINT

Point Operations

REAR AXLE CYLINDER

Point Operations

STEERING

SCRAPER

STEERING COLUMN

Point Operations

ORBITROL

Point Operations

TROUBLESHOOTING

BRAKE

GENERAL

SPECIFICATIONS

COMPONENTS

BRAKE UNIT

PARKING BRAKE

NEGATIVE BRAKE VERSION

BODY

COMPONENTS

OPERATORS SEAT

BATTERY COVER UNIT

OVERHEAD GUARD

COUNTERWEIGHT

REAR CHASSIS

MATERIAL HANDLING SYSTEM

HYDRAULIC CIRCUIT

NEGATIVE BRAKE HYDRAULIC DIAGRAM

COMPONENTS

OIL TANK

OIL FILTER AND AIR BREATHER PIPE

Point Operations

HYDRAULIC OIL

LIFTING LOAD DOWN TEST

NATURAL FORWARD TILTING TEST

OIL LEAK TEST

MAST

MAST

MAST GROUP (V) (4.0 - 5.0 t)

MAST GROUP (FV) (4.0 - 4.5 t)

MAST GROUP (FV) (5.0 t)

MAST GROUP (FSV) (4.0 - 4.5 t)

MAST GROUP (FSV) (5.0 t)

MAST GROUP (FW) (4.0 - 4.5 t) (OPT)

MAST GROUP (FW) (5.0 t) (OPT)

MAST GROUP (FSW) (4.0 - 4.5 t) (OPT)

MAST GROUP (FSW) (5.0 t) (OPT)

LIFTING BRACKET GROUP (V) (4.0 - 5.0 t)

LIFTING BRACKET GROUP (FV) (4.0 - 4.5 t)

LIFTING BRACKET GROUP (FV) (5.0 t)

LIFTING BRACKET GROUP (FSV) (4.0 - 4.5 t)

LIFTING BRACKET GROUP (FSV) (5.0 t)

LIFTING BRACKET GROUP (FW) (4.0 - 5.0 t) (OPT)

LIFTING BRACKET GROUP (FSW) (4.0 - 5.0 t) (OPT)

SIDESHIFT FORK CARRIAGE GROUP (V) (4.0 - 5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FV) (4.0 - 4.5 t)

SIDESHIFT FORK CARRIAGE GROUP (FV) (5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FSV) (4.0 - 4.5 t)

SIDESHIFT FORK CARRIAGE GROUP (FSV) (5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FW) (4.0 - 5.0 t) (OPT)

SIDESHIFT FORK CARRIAGE GROUP (FSW) (4.0 - 5.0 t) (OPT)

CHAIN AND CHAIN PULLEY GROUP (V) (4.0 - 5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FV) (4.0 - 4.5 t)

CHAIN AND CHAIN PULLEY GROUP (FV) (5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FSV) (4.0 - 4.5 t)

CHAIN AND CHAIN PULLEY GROUP (FSV) (5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FW) (4.0 - 5.0 t) (OPT)

CHAIN AND CHAIN PULLEY GROUP (FSW) (4.0 - 5.0 t) (OPT)

FORK CARRIAGE ASSEMBLY AND MAST REMOVAL

MAST GROUP (WITH FORK CARRIAGE)

MAST ASSEMBLY V

MAST GROUP FV

MAST GROUP FSV

FW MAST GROUP (OPT)

FSW MAST GROUP (OPT)

LIFTING BRACKET V - FV - FSV

LIFTING BRACKET FW - FSW (OPT)

REPLACING THE FORK CARRIAGE GUIDE PADS

ADJUSTING THE MAST V FV FSV

Adjusting the play on the inner mast roller (V - FV - FSV) and central mast lower roller (FSV)

Adjusting the play on the outer mast roller (V - FV - FSV) and central mast upper roller (FSV)

Adjusting the play on the lower/central/upper lifting roller

Adjusting the clearance of the inner mast roller

STANDARD FOR SELECTING AN OVERSIZE ROLLER

MAST ROLLER

CHAINS

FORK

ADJUSTING THE ADJUSTING RINGS ON THE LIFT CYLINDER ROD (TO AVOID IRREGULAR LIFTING)

CYLINDER

LIFTING CYLINDERS

SIDE LIFTING CYLINDERS V MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS V MAST (5.0 t)

SIDE LIFTING CYLINDERS FV MAST (4.0 - 4.5 t)

CENTRAL LIFTING CYLINDERS FV MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS FV MAST (5.0 t)

CENTRAL LIFTING CYLINDERS FV MAST (5.0 t)

SIDE LIFTING CYLINDERS FSV MAST (4.0 - 4.5 t)

CENTRAL LIFTING CYLINDERS FSV MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS FSV MAST (5.0 t)

CENTRAL LIFTING CYLINDERS FSV MAST (5.0 t)

FW MAST SIDE LIFTING CYLINDERS (4.0 - 4.5 t) (OPT)

FW MAST CENTRAL LIFTING CYLINDERS (4.0 - 4.5 t) (OPT)

FW MAST SIDE LIFTING CYLINDERS (5.0 t) (OPT)

FW MAST CENTRAL LIFTING CYLINDERS (5.0 t) (OPT)

FSW MAST SIDE LIFTING CYLINDER (4.0 - 4.5 t) (OPT)

FSW MAST CENTRAL LIFTING CYLINDER (4.0 - 4.5 t) (OPT)

FSW MAST SIDE LIFTING CYLINDERS (5.0 t) (OPT)

FSW MAST CENTRAL LIFTING CYLINDERS (5.0 t) (OPT)

DISASSEMBLYASSEMBLY

REMOVAL - INSPECTION - INSTALLATION

Point Operations

REMOVAL - INSPECTION - INSTALLATION

Point Operations

DISASSEMBLYASSEMBLY

REMOVAL - INSPECTION - INSTALLATION

TILTING CYLINDERS

Point Operations

OIL PUMP

SCRAPER

COMPONENTS

DISASSEMBLY-ASSEMBLY

OIL CONTROL VALVE

HYDRAULIC DIAGRAM

COMPONENTS

SPECIFICATIONS

DISASSEMBLY-ASSEMBLY

MAXIMUM PRESSURE ADJUSTMENT

SAS FUNCTION

GENERAL

FOR REPAIR WORK

HAND GRIP POSITION CORRECTION VALVE

STEERING POTENTIOMETER

Point Operations

TILT ANGLE POTENTIOMETER

Point Operations

MAST PRESSURE SENSOR

MAST HEIGHT SWITCH

YAW RATE SENSOR

OSCILLATION LOCK CYLINDER

Point Operations

ADJUSTMENT

MAIN OPTIONS

DC/DC CONVERTERS

REAR COMPARTMENT FUSES

FUSES UNDER DASHBOARD

HEIGHT SELECTOR

MAXIMUM HEIGHT LIMITER

HEIGHT LIMITER

AUTOMATIC HEIGHT CONTROL

BUMP SENSOR - DHU - KEYPAD

FLASH - ROTATING LAMP

WORK SPOTLIGHTS

COMBINED LIGHTS

HEATER - HEATED REAR WINDOW

WINDSCREEN WIPERS - RADIO - CAB LIGHT

APPENDIX

COMPONENTS

WIRING DIAGRAM

WIRING

This manual will assist you in assembling, disassembling, and repairing for your electric forklift truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

8FBMT40

8FBMT45

8FBMT50

Format: PDF, 702 pages

Language: English

Table of Contents:

GENERAL

VEHICLE EXTERIOR VIEW

VEHICLE MODELS

CHASSIS NUMBER

HOW TO USE THIS MANUAL

OPERATING TIPS

LIST OF SUSPENSION ROPE ANGLES

SAFETY LOAD FOR EACH SUSPENSION ROPE ANGLE

COMPONENT WEIGHTS

TOWING THE TRUCK

ELECTRICAL COMPONENTS INSPECTION

NOTES ON SAS

TIGHTENING TORQUE TABLE

TABLE OF LUBRICANTS AND FLUIDS

PERIODIC MAINTENANCE

SAS Periodic maintenance

BATTERY

BATTERY COMPARTMENT AND REQUIRED WEIGHT

STANDARD SERVICE VALUES

MULTI-DISPLAY FUNCTIONS

STATE OF BATTERY CHARGE INDICATOR

PROCEDURE SET TEMPERATURE SENSOR BATTERY

BATTERY MANAGEMENT PARAMETERS

TABLE OF BDI MAX, BDI MIN, RESET VOLT VALUES

BATTERY INDICATOR TROUBLESHOOTING

TROUBLESHOOTING

BATTERY UNIT

INSPECTION

STATE OF BATTERY CHARGE

BATTERY CAPACITY

GEL BATTERIES

REPLACING BATTERY PLUG TERMINALS

CONTROL SYSTEM

GENERAL

CAN-BUS CONNECTION

REAR COMPARTMENT FUSES

FUSES UNDER DASHBOARD

CONTACTORS

DC/DC CONVERTERS

LOGIC UNITS

CONTACTOR GROUP

MCB CARD

MULTI-DISPLAY FUNCTIONS

24-12 V FUSE CARD

ARMREST CARD

ARMREST CARD POTENTIOMETERS

ACCELERATOR POTENTIOMETER

STEERING POTENTIOMETER

[Point 1]

[Point 2]

TILT ANGLE POTENTIOMETER

[Point 1]

MAST PRESSURE SENSOR

MAST HEIGHT SWITCH

YAW RATE SENSOR

CALIBRATIONS

MULTI-FUNCTION DISPLAY

GENERAL

MENU MAP

OPERATOR MENU

ADMINISTRATOR MENU

ADMINISTRATOR menu screen (with vehicle startup using key)

ADMINISTRATOR menu screen (with vehicle startup using pin code via keypad)

MASK MENU

ANALYZER

TUNING

OPTION SET

MATCHING

OTHERS MENU

TROUBLESHOOTING

CONNECTOR CHECK

WIRE HARNESS AND CONNECTORS INSPECTION PROCEDURE

INSULATION CHECK PROCEDURE

MOTOR WINDING CHECK PROCEDURE

TEMPERATURE SENSOR CHECK PROCEDURE

CAN-BUS CHECK PROCEDURE

DIAGNOSTIC CODES LIST

WHEN AN ERROR CODE IS DISPLAYED

MOTOR

SENSOR

Point Operations

DISASSEMBLY-ASSEMBLY

PUMP MOTOR:

Point Operations

DRIVE UNIT and FRONT AXLE

GENERAL

COMPONENTS - STANDARD VERSION

COMPONENTS - NEGATIVE BRAKE VERSION

FRONT AXLE ASSEMBLY

Point Operations

MAINTENANCE

REAR AXLE

REAR AXLE ASSEMBLY

REAR AXLE

Point Operations

REAR AXLE HUB - CAST ARTICULATED JOINT

Point Operations

REAR AXLE CYLINDER

Point Operations

STEERING

SCRAPER

STEERING COLUMN

Point Operations

ORBITROL

Point Operations

TROUBLESHOOTING

BRAKE

GENERAL

SPECIFICATIONS

COMPONENTS

BRAKE UNIT

PARKING BRAKE

NEGATIVE BRAKE VERSION

BODY

COMPONENTS

OPERATORS SEAT

BATTERY COVER UNIT

OVERHEAD GUARD

COUNTERWEIGHT

REAR CHASSIS

MATERIAL HANDLING SYSTEM

HYDRAULIC CIRCUIT

NEGATIVE BRAKE HYDRAULIC DIAGRAM

COMPONENTS

OIL TANK

OIL FILTER AND AIR BREATHER PIPE

Point Operations

HYDRAULIC OIL

LIFTING LOAD DOWN TEST

NATURAL FORWARD TILTING TEST

OIL LEAK TEST

MAST

MAST

MAST GROUP (V) (4.0 - 5.0 t)

MAST GROUP (FV) (4.0 - 4.5 t)

MAST GROUP (FV) (5.0 t)

MAST GROUP (FSV) (4.0 - 4.5 t)

MAST GROUP (FSV) (5.0 t)

MAST GROUP (FW) (4.0 - 4.5 t) (OPT)

MAST GROUP (FW) (5.0 t) (OPT)

MAST GROUP (FSW) (4.0 - 4.5 t) (OPT)

MAST GROUP (FSW) (5.0 t) (OPT)

LIFTING BRACKET GROUP (V) (4.0 - 5.0 t)

LIFTING BRACKET GROUP (FV) (4.0 - 4.5 t)

LIFTING BRACKET GROUP (FV) (5.0 t)

LIFTING BRACKET GROUP (FSV) (4.0 - 4.5 t)

LIFTING BRACKET GROUP (FSV) (5.0 t)

LIFTING BRACKET GROUP (FW) (4.0 - 5.0 t) (OPT)

LIFTING BRACKET GROUP (FSW) (4.0 - 5.0 t) (OPT)

SIDESHIFT FORK CARRIAGE GROUP (V) (4.0 - 5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FV) (4.0 - 4.5 t)

SIDESHIFT FORK CARRIAGE GROUP (FV) (5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FSV) (4.0 - 4.5 t)

SIDESHIFT FORK CARRIAGE GROUP (FSV) (5.0 t)

SIDESHIFT FORK CARRIAGE GROUP (FW) (4.0 - 5.0 t) (OPT)

SIDESHIFT FORK CARRIAGE GROUP (FSW) (4.0 - 5.0 t) (OPT)

CHAIN AND CHAIN PULLEY GROUP (V) (4.0 - 5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FV) (4.0 - 4.5 t)

CHAIN AND CHAIN PULLEY GROUP (FV) (5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FSV) (4.0 - 4.5 t)

CHAIN AND CHAIN PULLEY GROUP (FSV) (5.0 t)

CHAIN AND CHAIN PULLEY GROUP (FW) (4.0 - 5.0 t) (OPT)

CHAIN AND CHAIN PULLEY GROUP (FSW) (4.0 - 5.0 t) (OPT)

FORK CARRIAGE ASSEMBLY AND MAST REMOVAL

MAST GROUP (WITH FORK CARRIAGE)

MAST ASSEMBLY V

MAST GROUP FV

MAST GROUP FSV

FW MAST GROUP (OPT)

FSW MAST GROUP (OPT)

LIFTING BRACKET V - FV - FSV

LIFTING BRACKET FW - FSW (OPT)

REPLACING THE FORK CARRIAGE GUIDE PADS

ADJUSTING THE MAST V FV FSV

Adjusting the play on the inner mast roller (V - FV - FSV) and central mast lower roller (FSV)

Adjusting the play on the outer mast roller (V - FV - FSV) and central mast upper roller (FSV)

Adjusting the play on the lower/central/upper lifting roller

Adjusting the clearance of the inner mast roller

STANDARD FOR SELECTING AN OVERSIZE ROLLER

MAST ROLLER

CHAINS

FORK

ADJUSTING THE ADJUSTING RINGS ON THE LIFT CYLINDER ROD (TO AVOID IRREGULAR LIFTING)

CYLINDER

LIFTING CYLINDERS

SIDE LIFTING CYLINDERS V MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS V MAST (5.0 t)

SIDE LIFTING CYLINDERS FV MAST (4.0 - 4.5 t)

CENTRAL LIFTING CYLINDERS FV MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS FV MAST (5.0 t)

CENTRAL LIFTING CYLINDERS FV MAST (5.0 t)

SIDE LIFTING CYLINDERS FSV MAST (4.0 - 4.5 t)

CENTRAL LIFTING CYLINDERS FSV MAST (4.0 - 4.5 t)

SIDE LIFTING CYLINDERS FSV MAST (5.0 t)

CENTRAL LIFTING CYLINDERS FSV MAST (5.0 t)

FW MAST SIDE LIFTING CYLINDERS (4.0 - 4.5 t) (OPT)

FW MAST CENTRAL LIFTING CYLINDERS (4.0 - 4.5 t) (OPT)

FW MAST SIDE LIFTING CYLINDERS (5.0 t) (OPT)

FW MAST CENTRAL LIFTING CYLINDERS (5.0 t) (OPT)

FSW MAST SIDE LIFTING CYLINDER (4.0 - 4.5 t) (OPT)

FSW MAST CENTRAL LIFTING CYLINDER (4.0 - 4.5 t) (OPT)

FSW MAST SIDE LIFTING CYLINDERS (5.0 t) (OPT)

FSW MAST CENTRAL LIFTING CYLINDERS (5.0 t) (OPT)

DISASSEMBLYASSEMBLY

REMOVAL - INSPECTION - INSTALLATION

Point Operations

REMOVAL - INSPECTION - INSTALLATION

Point Operations

DISASSEMBLYASSEMBLY

REMOVAL - INSPECTION - INSTALLATION

TILTING CYLINDERS

Point Operations

OIL PUMP

SCRAPER

COMPONENTS

DISASSEMBLY-ASSEMBLY

OIL CONTROL VALVE

HYDRAULIC DIAGRAM

COMPONENTS

SPECIFICATIONS

DISASSEMBLY-ASSEMBLY

MAXIMUM PRESSURE ADJUSTMENT

SAS FUNCTION

GENERAL

FOR REPAIR WORK

HAND GRIP POSITION CORRECTION VALVE

STEERING POTENTIOMETER

Point Operations

TILT ANGLE POTENTIOMETER

Point Operations

MAST PRESSURE SENSOR

MAST HEIGHT SWITCH

YAW RATE SENSOR

OSCILLATION LOCK CYLINDER

Point Operations

ADJUSTMENT

MAIN OPTIONS

DC/DC CONVERTERS

REAR COMPARTMENT FUSES

FUSES UNDER DASHBOARD

HEIGHT SELECTOR

MAXIMUM HEIGHT LIMITER

HEIGHT LIMITER

AUTOMATIC HEIGHT CONTROL

BUMP SENSOR - DHU - KEYPAD

FLASH - ROTATING LAMP

WORK SPOTLIGHTS

COMBINED LIGHTS

HEATER - HEATED REAR WINDOW

WINDSCREEN WIPERS - RADIO - CAB LIGHT

APPENDIX

COMPONENTS

WIRING DIAGRAM

WIRING

Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары