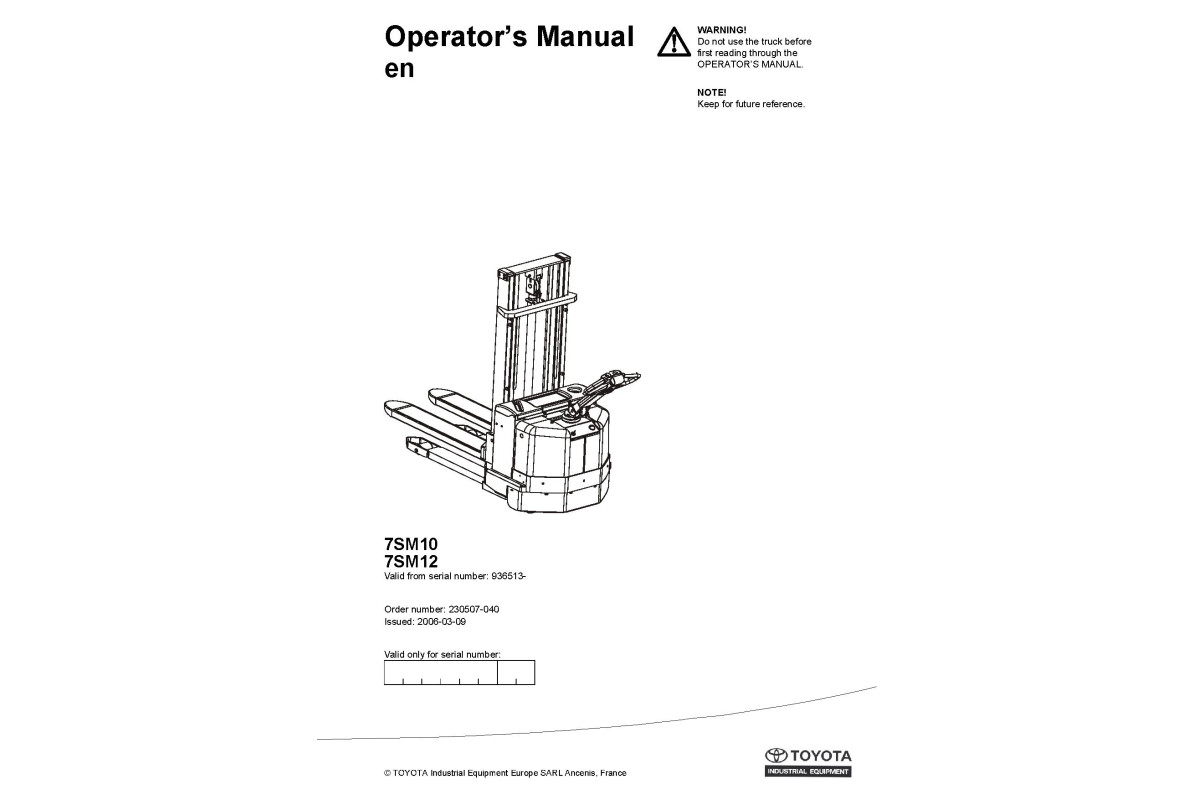

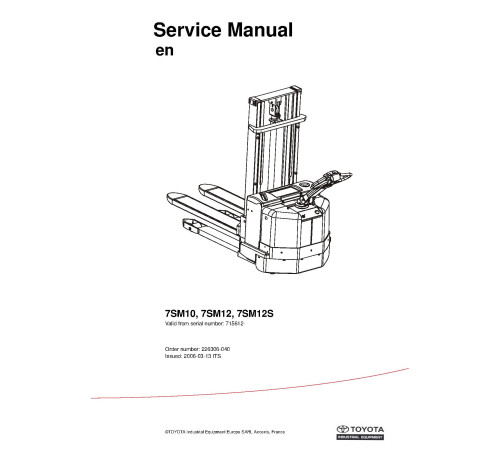

Illustrated factory set of Service Manuals for Toyota Pallet Stackers Models 7SM10 and 7SM12 (SN:936513-up).

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your pallet stacker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

7SM10 (SN:936513-up)

7SM12 (SN:936513-up)

The manual comprises 2 documents, including the Service Manual, and Operate and Maintenance manual

1. Service Manual (SM-226306-040)

Format: PDF, 182 pages

Language: English

Table of Contents:

General product information - M2

Intended application of the truck

Prohibited application of the truck

Truck data

Truck dimensions

Identification plate

Capacity plate

Modification plate

Main components

Warning and information plates and symbols

Technical data - M4

Introduction Maintenance - P1

Safety regulations with maintenance work

Cleaning and washing

Safe lifting

Preventive maintenance - P2

Maintenance schedule

Lubrication schedule

Oil and grease specification - P3

Tools - P4

Super Seal connectors

AMP connectors

Molex connectors

Grease guns

Other tools

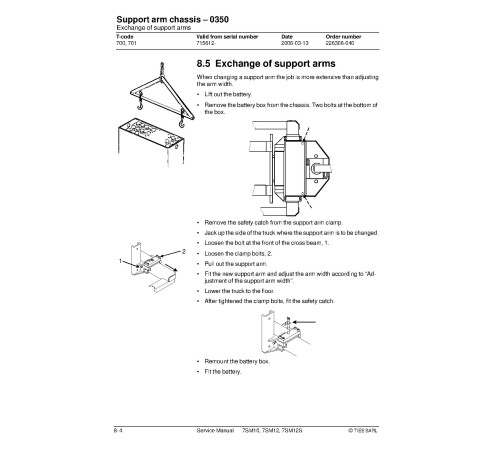

Support arm chassis - 0350

General

Main components

Maintenance

Adjustment of the support arm width

Exchange of support arms

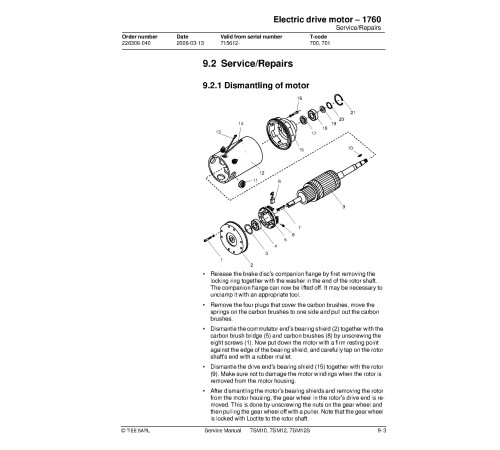

Electric drive motor - 1760

Component parts

Service/Repairs

Technical data

Drive unit/gear - 2550

Component parts

Leakage from top cover

Changing of the drive shaft’s sealing ring

Electro magnetic brake - 3370

Main components

Maintenance

Steering - 4000

Component parts, tiller arm

Adjustments

Tiller arm handle

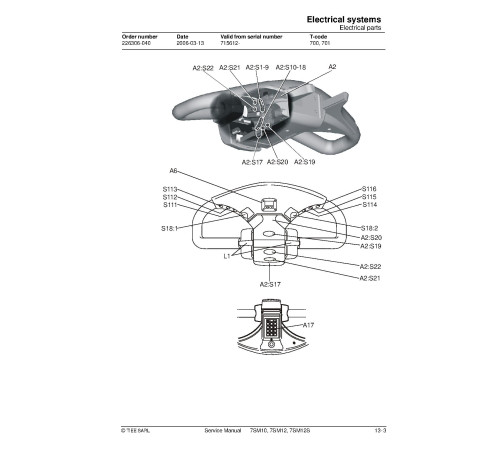

Electrical systems

General

Electrical parts

Electrical wiring diagram

Functional description

Parameters

Diagnostic and troubleshooting

Technical specifications - Curtis 1243

Hydraulic system - 6000

General

Hydraulic diagram and components

Lifting Mast - 7000

Grease the beam flanges and beam ribs

Main lift chain system

Cleaning

Lubrication

Battery charger (built-in) - 8340

General

Technical data - charger

Charging

Troubleshooting and service

Setting the charger (applies to machine numbers 723984-936512)

Control/computer equipment - 8700

General

Connection

Layout

Connection function

Disconnection function

Downloading program function

Truck report function

Parameters function

Diagnostics function

Other menu functions

Specifications

Installation

2. Operate and Maintenance manual (UM-230507-040)

Format: PDF, 65 pages

Language: English

Table of Contents:

SM10 7SM12

Valid from serial number: 936513-

Order number: 230507-040

Safety regulations

Warning symbols

General safety regulations

Warning and information plates and symbols

Hydraulic control: Lifting/Lowering

Travel direction

Signal/Horn

Capacity plate

Identification plate

Hydraulic control: Lower

Serial number

Hydraulic oil filling

Maximum height for rated capacity

A) Do not walk under an elevated load B) Do not stand on the forks

Lifting points

Modification plate.

Presentation of the truck

Intended application of the truck

Prohibited application of the truck

Truck data

Truck dimensions

Identification plate

Capacity plate

Modification plate

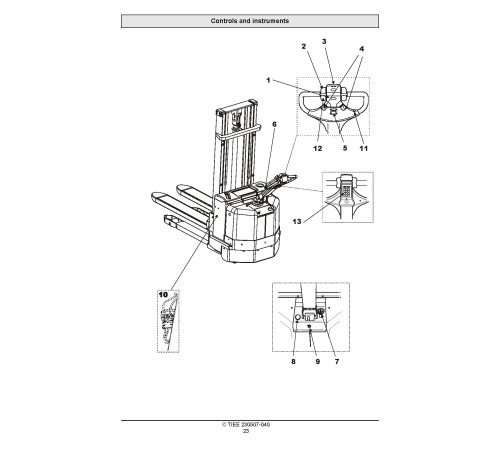

Main components

Tiller arm: The truck is manoeuvred by the driver while walking. 208 degree steering area. The brakes are applied in the tiller arm’s upper and lower positions.

Identification plate: With model designation, serial number, year of manufacture, weight without battery, battery weight, rated capacity, battery voltage and manufacturer.

Covers: Removable which provides good accessibility when servicing.

Emergency switch off

Hydraulic control: For controlling lifting and lowering functions.

Hydraulic unit: Pump motor, pump and oil tank are integrated in a compact unit.

Hydraulic valves: The valves are located to provide easy access.

Drive unit with brake: Suspended drive unit with spring-loaded mechanical brake, travel motor, gears and drive wheel combined into a compact unit. Steering bearings between motor and gears.

Serial number: The serial number plate fitted to the chassis.

Electric panel: Removable, which provides good access when servicing. 24 volt electrical supply. The speed is variably controlled by means of a transistor.

Support castor wheels Two support castor wheels to ensure stability.

Battery: 24V with different Ah values. The battery is automatically locked in the battery compartment.

Battery connector: The battery is charged via the battery connector, which is usually connected to the battery disconnector.

Mast: Fitted with a finger guard to cover the driver's normal reach.

Controls and instruments

Control for lifting and lowering the forks

Travel direction selector and speed control

Switch for safety reversing

Horn

Display

Tiller arm and brake

Control for lowering the forks

Emergency switch off

Key switch

Battery connector

Turtle button (Option)

Click-2-Creep function (Option)

Keypad (Option)

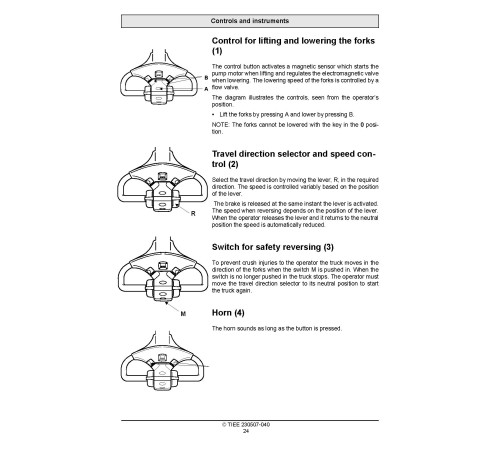

Control for lifting and lowering the forks (1)

Travel direction selector and speed control (2)

Switch for safety reversing (3)

Horn (4)

Display (5)

Function

Tiller arm and brake (6)

Control for lowering the forks (7)

Emergency switch off (8)

Key switch (9)

Battery connector (10)

Display and programming

Display

Programming

Warning codes

Error codes

Accessories

Platform

Load support

Pen holder

Integrated charger

Turtle button

Click-2-Creep function

Keypad

ID unit

Driving

Starting the truck

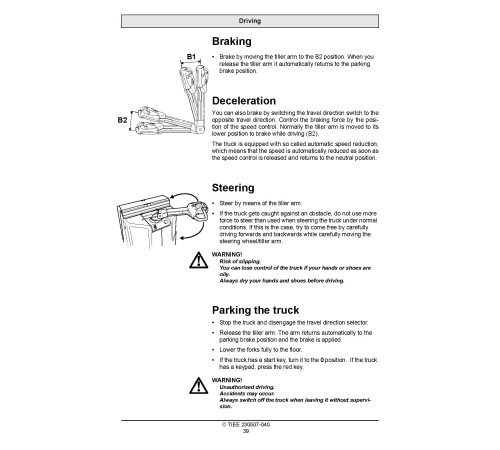

Braking

Deceleration

Steering

Parking the truck

Transporting loads

WARNING!

WARNING!

WARNING!

WARNING!

WARNING

WARNING!

WARNING!

Collecting a load

Depositing a load

Battery

Replacing the battery

Charging the battery

Battery maintenance

Daily service and function checks

WARNING!

Pos no

Check points

Action

Maintenance

Safety regulations with maintenance work

Maintenance work that is to be carried out by the operator

Maintenance work that may be carried out by trained maintenance personnel

Cleaning and washing

Maintenance chart

Lubrication chart

Oil and grease specification

Transporting and storing the truck

The truck’s dimensions and weight as standard

Lifting the truck

Towing and transporting a defective truck

Storing the truck

Starting after a period of disuse

Recycling/discarding

Discarding the battery

Scrapping the truck

________________

This manuals will assist you in diagnosing, analyses, testing, repair, operating, and maintaining for your pallet stacker.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

7SM10 (SN:936513-up)

7SM12 (SN:936513-up)

The manual comprises 2 documents, including the Service Manual, and Operate and Maintenance manual

1. Service Manual (SM-226306-040)

Format: PDF, 182 pages

Language: English

Table of Contents:

General product information - M2

Intended application of the truck

Prohibited application of the truck

Truck data

Truck dimensions

Identification plate

Capacity plate

Modification plate

Main components

Warning and information plates and symbols

Technical data - M4

Introduction Maintenance - P1

Safety regulations with maintenance work

Cleaning and washing

Safe lifting

Preventive maintenance - P2

Maintenance schedule

Lubrication schedule

Oil and grease specification - P3

Tools - P4

Super Seal connectors

AMP connectors

Molex connectors

Grease guns

Other tools

Support arm chassis - 0350

General

Main components

Maintenance

Adjustment of the support arm width

Exchange of support arms

Electric drive motor - 1760

Component parts

Service/Repairs

Technical data

Drive unit/gear - 2550

Component parts

Leakage from top cover

Changing of the drive shaft’s sealing ring

Electro magnetic brake - 3370

Main components

Maintenance

Steering - 4000

Component parts, tiller arm

Adjustments

Tiller arm handle

Electrical systems

General

Electrical parts

Electrical wiring diagram

Functional description

Parameters

Diagnostic and troubleshooting

Technical specifications - Curtis 1243

Hydraulic system - 6000

General

Hydraulic diagram and components

Lifting Mast - 7000

Grease the beam flanges and beam ribs

Main lift chain system

Cleaning

Lubrication

Battery charger (built-in) - 8340

General

Technical data - charger

Charging

Troubleshooting and service

Setting the charger (applies to machine numbers 723984-936512)

Control/computer equipment - 8700

General

Connection

Layout

Connection function

Disconnection function

Downloading program function

Truck report function

Parameters function

Diagnostics function

Other menu functions

Specifications

Installation

2. Operate and Maintenance manual (UM-230507-040)

Format: PDF, 65 pages

Language: English

Table of Contents:

SM10 7SM12

Valid from serial number: 936513-

Order number: 230507-040

Safety regulations

Warning symbols

General safety regulations

Warning and information plates and symbols

Hydraulic control: Lifting/Lowering

Travel direction

Signal/Horn

Capacity plate

Identification plate

Hydraulic control: Lower

Serial number

Hydraulic oil filling

Maximum height for rated capacity

A) Do not walk under an elevated load B) Do not stand on the forks

Lifting points

Modification plate.

Presentation of the truck

Intended application of the truck

Prohibited application of the truck

Truck data

Truck dimensions

Identification plate

Capacity plate

Modification plate

Main components

Tiller arm: The truck is manoeuvred by the driver while walking. 208 degree steering area. The brakes are applied in the tiller arm’s upper and lower positions.

Identification plate: With model designation, serial number, year of manufacture, weight without battery, battery weight, rated capacity, battery voltage and manufacturer.

Covers: Removable which provides good accessibility when servicing.

Emergency switch off

Hydraulic control: For controlling lifting and lowering functions.

Hydraulic unit: Pump motor, pump and oil tank are integrated in a compact unit.

Hydraulic valves: The valves are located to provide easy access.

Drive unit with brake: Suspended drive unit with spring-loaded mechanical brake, travel motor, gears and drive wheel combined into a compact unit. Steering bearings between motor and gears.

Serial number: The serial number plate fitted to the chassis.

Electric panel: Removable, which provides good access when servicing. 24 volt electrical supply. The speed is variably controlled by means of a transistor.

Support castor wheels Two support castor wheels to ensure stability.

Battery: 24V with different Ah values. The battery is automatically locked in the battery compartment.

Battery connector: The battery is charged via the battery connector, which is usually connected to the battery disconnector.

Mast: Fitted with a finger guard to cover the driver's normal reach.

Controls and instruments

Control for lifting and lowering the forks

Travel direction selector and speed control

Switch for safety reversing

Horn

Display

Tiller arm and brake

Control for lowering the forks

Emergency switch off

Key switch

Battery connector

Turtle button (Option)

Click-2-Creep function (Option)

Keypad (Option)

Control for lifting and lowering the forks (1)

Travel direction selector and speed control (2)

Switch for safety reversing (3)

Horn (4)

Display (5)

Function

Tiller arm and brake (6)

Control for lowering the forks (7)

Emergency switch off (8)

Key switch (9)

Battery connector (10)

Display and programming

Display

Programming

Warning codes

Error codes

Accessories

Platform

Load support

Pen holder

Integrated charger

Turtle button

Click-2-Creep function

Keypad

ID unit

Driving

Starting the truck

Braking

Deceleration

Steering

Parking the truck

Transporting loads

WARNING!

WARNING!

WARNING!

WARNING!

WARNING

WARNING!

WARNING!

Collecting a load

Depositing a load

Battery

Replacing the battery

Charging the battery

Battery maintenance

Daily service and function checks

WARNING!

Pos no

Check points

Action

Maintenance

Safety regulations with maintenance work

Maintenance work that is to be carried out by the operator

Maintenance work that may be carried out by trained maintenance personnel

Cleaning and washing

Maintenance chart

Lubrication chart

Oil and grease specification

Transporting and storing the truck

The truck’s dimensions and weight as standard

Lifting the truck

Towing and transporting a defective truck

Storing the truck

Starting after a period of disuse

Recycling/discarding

Discarding the battery

Scrapping the truck

________________

Included

Service Manual

1Operate and Maintenance manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары