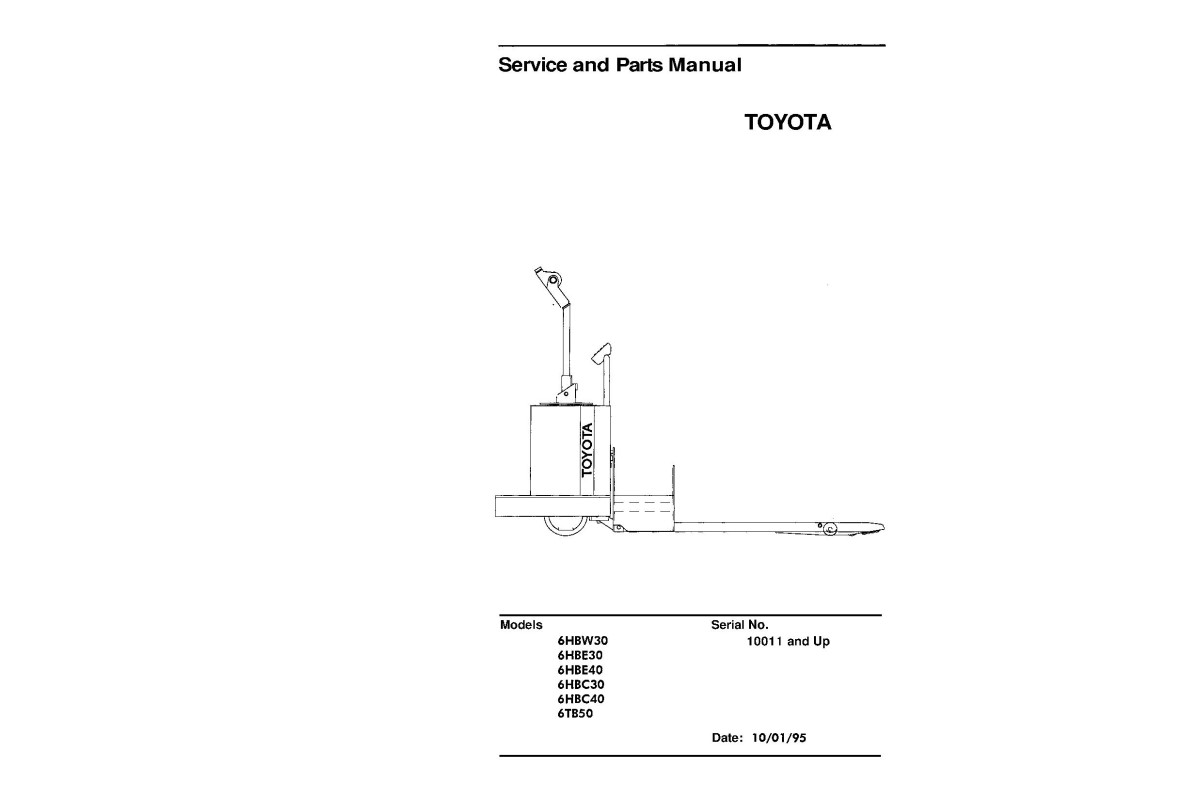

Illustrated factory Service Manual for Toyota Pallet Trucks Models 6HBW30, 6HBE30, 6HBE40, 6HBC30, 6HBC40 and 6TB50 (SN:10011-20010).

This manual will assist you in diagnosing, analyses, testing, and repair for your pallet truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

6HBW30 (SN:10011-20010)

6HBE30 (SN:10011-20010)

6HBE40 (SN:10011-20010)

6HBC30 (SN:10011-20010)

6HBC40 (SN:10011-20010)

6TB50 (SN:10011-20010)

Format: PDF, 313 pages

Language: English

Table of Contents:

R/M 6HBW/E/C30, 6HBE/C40 & 6TB50 SN: 10,011-20,010

SECTION I: Service Manual

Description

Overview

Vehicle Specifications

Description

Mechanical

Drive Unit

Handle Assembly

Coast Control

Drum Brake

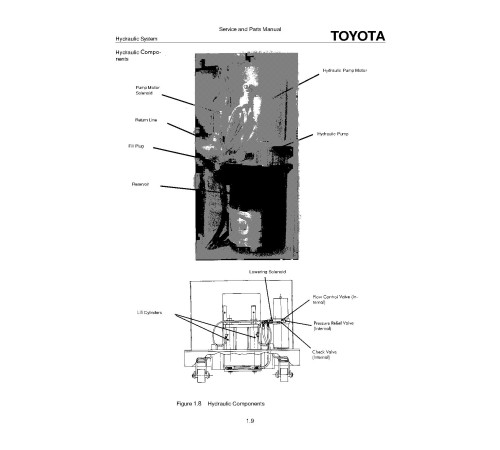

Hydraulic System

General

Pressure Relief Valve

Flow Control Valve

Lowering Solenoid

Lift Cylinders

Hydraulic Reservoir

Breather Cap

Hydraulic Pump Motor

Hydraulic Pump

Check Valve

Hydraulic Components

Electrical System

Battery

Drive Motor

Contactors

Lift Limit Switch

Advanced Transistor Control (Motor Controller)

Model 6HBW30

Models 6HBE30 and 6HBE40

Models 6HBC30 and 6HBC40

Model 6TB50

Operating Instructions

Installation

Visual Inspection

Checking the Battery

Hydrometer Use

Adding Water To Battery

Voltage Check

Connecting the Battery

Lubrication

Checking the Hydraulic System

Cold Storage Conditioning

Classes Of Cold Storage

Operational Checks

Brake

Fork/Lift Linkage

Emergency Reverse Switch

Coast Control

Receiving Inspection Guide .

Break-In Period

Introduction

Motors

Pump

Battery

Theory of Operation

Advanced Transistor Control

Section Overview

System Overview

Advanced Transistor Control (AT)

Current Limiting

Low Voltage Cutback

Thermal Protection

Runaway Protection

Static Return to Neutral Protection

Plugging

Controller Key Switch Input

Controller Thumbwheel Throttle Inputs

'Emergency Reverse' Plug Breaking Inhibit

Control Module

Battery Plugged IN

Battery Plugged IN/Key Switch Turned to ON or TURTLE

Battery Plugged IN/Key Switch Turned ON/Deadman Switch Closed

Directional/Speed Control Forward

Diredional/Speed Control-High Speed (FORWARD ONLY)

Emergency Reverse Switch

Plugging

Turtle Speed

Lift/Lower System

Lift

Lower

Maintenance

Scheduled Maintenance

Lubrication and Maintenance

Daily or Every 8 Operating HoursWhichever Occurs First

Weekly or Every 50 Operating HoursWhichever Occurs First

Monthly or Every 200 Operating HoursWhichever Occurs First

Every 500 Hours

Semiannually or Every 1000 HoursWhichever Occurs First

Lubrication and Maintenance Guide

Hydraulic System Oil

Welding Precautions

Power Section

Drive Unit

Drive Unit Service

Drive Housing Lubrication

Drive Housing Vent Plug

Drive Housing Steering Bearing

Mechanical

Drive Unit Assembly

Drive Unit Tooth Pattern

Drive Gear Case Data

Gear Checking Procedure

Drive Unit Installation

Brake

Daily Inspection

After Every 500 Hours of Operation

Brake Adjustment (For all Models)

Deadman Switch Adjustment

Handle Return Spring Adjustment

Drive Wheel

Daily Inspection

After Every 50 Hours of Operation

After Every 200 Hours of Operation

Cushion Drive Tire Replacement

Load Wheels

Inspection

Service

Wheel Replacement (Model 6HBE30 & 6HBC30)

Wheel Replacement (Model 6HBE40 & 6HBC40)

Pallet Entry Wheels

Daily Inspection

After Every 50 Hours of Operation

After Every 500 Hours of Operation

Wheel Replacement

Casters

Daily Inspection

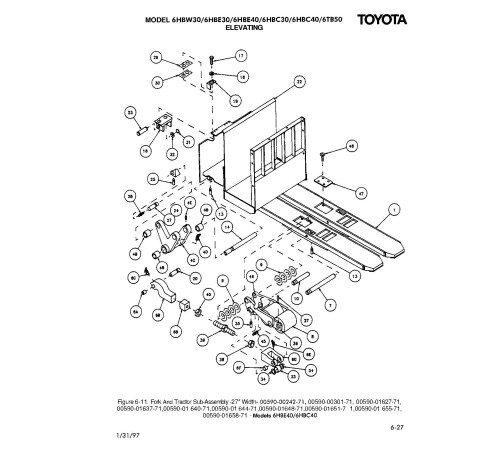

Fork And Linkage

After Every 50 Hours of Operation

Fork Height Adjustment

Lowered Fork Height

Lift Limit Switch Adjustment

Hydraulic

Inspection

500 Hours

Hydraulic Reservoir

Checking and Adjusting Hydraulic Pump Relief Valv

Relief Valve Setting

Hydraulic Reservoir

Inspection Every 8 Hours

Lift Cylinders Service

Oil Leakage Wiper Seal

Inspection Every 200 Hours

Cleaning Breather Cap

Inspection Every 1, 000 Hours

Electrical

Battery

ElectrolyteLevel

Specific Gravity

Battery Exterior

Battery Charging

Battery Storage

Motors

Inspection

Brushes

Commutator

Inspection

Servicing

High Mica

Resurfacing

Drive Motor General Data

Drive Motor Inspection

Drive Motor Removal

Drive Motor Replacement

Lift Motor General Data

Inspection

Removal

Traction System Adjustments

Potentiometer Adjustments

Current Limit Setting

Plug Current Adjustment

Acceleration Adjustment

Potentiometer

Deadman Switch Adjustment

Contactors

Cleaning

Inspection

Tip Inspection

Contactor Table

Contactor Coil Replacement

Replacement Of Contactor Tips, Insulation And/or Core And Rod Assembly

ContactorDisassembly/Reassembly

Checking Components

Diodes

Plug Diode Test

Throttle Potentiometer Setting

Example

Turtle Speed Module (DA2)

Test/Adjustment

Replacenrent

Emergency Reverse Module (DA1)

Test Procedure

Testing Other Electrical Components

Troubleshooting

Overview

Field Replaceable Units (FRU)

Wiring Inspection Procedure

Traction System Problems

Does Not Run Directional Contactors Do Not Close

Does Not Run Directional Contactors Energize

Runs In One Direction Only Opposite Direction Contactor Does Not Energize

Runs In One Direction Only Directional Contactors Work Normally

Does Not Run In High Speed (Forward only)

Plugging Does Not Operate Properly

Does Not Accelerate Properly

Emergency Reverse Module Does Not Activate When Button Is Depressed

Emergency Reverse Module Checks OK No Reverse Travel With S25 Depressed

Lift/Lower Problems

Forks Do Not Lift When Lift Button Is Pushed

Forks Do Not Lower When Lower Button Is Pushed

Appendix

Lubrication Equivalency Chart

Standard Torque Data for Bolts

Conversion Table

Decimal Equivalency Chart

Schematic Legend

Electrical Schematic

Hydraulic Schematic

Electrical Schematic (Cold Storage)

Special Supplement

Alphabetical Index

SECTION II: Parts Manual

Chapter 1: Power Section

Chapter 2: Brake and Steering

Chapter 3: Drive Unit

Chapter 4: Electrical

Chapter 5: Hydraulic

Chapter 6: Elevating Section/Attachment

Alphabetical Index

Part Number Index

This manual will assist you in diagnosing, analyses, testing, and repair for your pallet truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

6HBW30 (SN:10011-20010)

6HBE30 (SN:10011-20010)

6HBE40 (SN:10011-20010)

6HBC30 (SN:10011-20010)

6HBC40 (SN:10011-20010)

6TB50 (SN:10011-20010)

Format: PDF, 313 pages

Language: English

Table of Contents:

R/M 6HBW/E/C30, 6HBE/C40 & 6TB50 SN: 10,011-20,010

SECTION I: Service Manual

Description

Overview

Vehicle Specifications

Description

Mechanical

Drive Unit

Handle Assembly

Coast Control

Drum Brake

Hydraulic System

General

Pressure Relief Valve

Flow Control Valve

Lowering Solenoid

Lift Cylinders

Hydraulic Reservoir

Breather Cap

Hydraulic Pump Motor

Hydraulic Pump

Check Valve

Hydraulic Components

Electrical System

Battery

Drive Motor

Contactors

Lift Limit Switch

Advanced Transistor Control (Motor Controller)

Model 6HBW30

Models 6HBE30 and 6HBE40

Models 6HBC30 and 6HBC40

Model 6TB50

Operating Instructions

Installation

Visual Inspection

Checking the Battery

Hydrometer Use

Adding Water To Battery

Voltage Check

Connecting the Battery

Lubrication

Checking the Hydraulic System

Cold Storage Conditioning

Classes Of Cold Storage

Operational Checks

Brake

Fork/Lift Linkage

Emergency Reverse Switch

Coast Control

Receiving Inspection Guide .

Break-In Period

Introduction

Motors

Pump

Battery

Theory of Operation

Advanced Transistor Control

Section Overview

System Overview

Advanced Transistor Control (AT)

Current Limiting

Low Voltage Cutback

Thermal Protection

Runaway Protection

Static Return to Neutral Protection

Plugging

Controller Key Switch Input

Controller Thumbwheel Throttle Inputs

'Emergency Reverse' Plug Breaking Inhibit

Control Module

Battery Plugged IN

Battery Plugged IN/Key Switch Turned to ON or TURTLE

Battery Plugged IN/Key Switch Turned ON/Deadman Switch Closed

Directional/Speed Control Forward

Diredional/Speed Control-High Speed (FORWARD ONLY)

Emergency Reverse Switch

Plugging

Turtle Speed

Lift/Lower System

Lift

Lower

Maintenance

Scheduled Maintenance

Lubrication and Maintenance

Daily or Every 8 Operating HoursWhichever Occurs First

Weekly or Every 50 Operating HoursWhichever Occurs First

Monthly or Every 200 Operating HoursWhichever Occurs First

Every 500 Hours

Semiannually or Every 1000 HoursWhichever Occurs First

Lubrication and Maintenance Guide

Hydraulic System Oil

Welding Precautions

Power Section

Drive Unit

Drive Unit Service

Drive Housing Lubrication

Drive Housing Vent Plug

Drive Housing Steering Bearing

Mechanical

Drive Unit Assembly

Drive Unit Tooth Pattern

Drive Gear Case Data

Gear Checking Procedure

Drive Unit Installation

Brake

Daily Inspection

After Every 500 Hours of Operation

Brake Adjustment (For all Models)

Deadman Switch Adjustment

Handle Return Spring Adjustment

Drive Wheel

Daily Inspection

After Every 50 Hours of Operation

After Every 200 Hours of Operation

Cushion Drive Tire Replacement

Load Wheels

Inspection

Service

Wheel Replacement (Model 6HBE30 & 6HBC30)

Wheel Replacement (Model 6HBE40 & 6HBC40)

Pallet Entry Wheels

Daily Inspection

After Every 50 Hours of Operation

After Every 500 Hours of Operation

Wheel Replacement

Casters

Daily Inspection

Fork And Linkage

After Every 50 Hours of Operation

Fork Height Adjustment

Lowered Fork Height

Lift Limit Switch Adjustment

Hydraulic

Inspection

500 Hours

Hydraulic Reservoir

Checking and Adjusting Hydraulic Pump Relief Valv

Relief Valve Setting

Hydraulic Reservoir

Inspection Every 8 Hours

Lift Cylinders Service

Oil Leakage Wiper Seal

Inspection Every 200 Hours

Cleaning Breather Cap

Inspection Every 1, 000 Hours

Electrical

Battery

ElectrolyteLevel

Specific Gravity

Battery Exterior

Battery Charging

Battery Storage

Motors

Inspection

Brushes

Commutator

Inspection

Servicing

High Mica

Resurfacing

Drive Motor General Data

Drive Motor Inspection

Drive Motor Removal

Drive Motor Replacement

Lift Motor General Data

Inspection

Removal

Traction System Adjustments

Potentiometer Adjustments

Current Limit Setting

Plug Current Adjustment

Acceleration Adjustment

Potentiometer

Deadman Switch Adjustment

Contactors

Cleaning

Inspection

Tip Inspection

Contactor Table

Contactor Coil Replacement

Replacement Of Contactor Tips, Insulation And/or Core And Rod Assembly

ContactorDisassembly/Reassembly

Checking Components

Diodes

Plug Diode Test

Throttle Potentiometer Setting

Example

Turtle Speed Module (DA2)

Test/Adjustment

Replacenrent

Emergency Reverse Module (DA1)

Test Procedure

Testing Other Electrical Components

Troubleshooting

Overview

Field Replaceable Units (FRU)

Wiring Inspection Procedure

Traction System Problems

Does Not Run Directional Contactors Do Not Close

Does Not Run Directional Contactors Energize

Runs In One Direction Only Opposite Direction Contactor Does Not Energize

Runs In One Direction Only Directional Contactors Work Normally

Does Not Run In High Speed (Forward only)

Plugging Does Not Operate Properly

Does Not Accelerate Properly

Emergency Reverse Module Does Not Activate When Button Is Depressed

Emergency Reverse Module Checks OK No Reverse Travel With S25 Depressed

Lift/Lower Problems

Forks Do Not Lift When Lift Button Is Pushed

Forks Do Not Lower When Lower Button Is Pushed

Appendix

Lubrication Equivalency Chart

Standard Torque Data for Bolts

Conversion Table

Decimal Equivalency Chart

Schematic Legend

Electrical Schematic

Hydraulic Schematic

Electrical Schematic (Cold Storage)

Special Supplement

Alphabetical Index

SECTION II: Parts Manual

Chapter 1: Power Section

Chapter 2: Brake and Steering

Chapter 3: Drive Unit

Chapter 4: Electrical

Chapter 5: Hydraulic

Chapter 6: Elevating Section/Attachment

Alphabetical Index

Part Number Index

Included

Service Manual

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары