All-Inclusive Factory Service Technical manual for OM Pimespo Palet Trucks Models XLOGO1 (4539 series) and XLOGO2 (4549 series).

This manuals will assist you in diagnosing, repairing, operating, maintaining, and finding spare parts for your palet truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

XLOGO1 (4539 series)

XLOGO2 (4549 series)

The manual comprises 3 documents, including the Workshop Manual, Operate and Maintenance manual, and Parts Catalog

1. Workshop Manual (453980423011_Ed_03-06_EN)

Format: PDF, 226 pages

Language: English

Table of Contents:

General information

Product information

Safety Regulations

Technical assistance

Maintenance

Diagnostics

Connectors for diagnostics

Curtis plant diagnostics

LES electrical drive diagnostics

Motor

Drive motor

Reducer

Disassembly / Reassembly of the reducer

Reducer maintenance

Carriage

Bonnets

Steering

Electrical steering

Tiller

Wheels and lever systems

Wheels

Braking

Braking devices and methods

Service braking (eABS)

Electrical and electronic system

Electrical-electronic system in general.

Wiring

Batteries

Hydraulic system

Hydraulic diagrams

Hydraulic components

Control unit and accumulator

Lifting

Fork lifting

Platform

Cylinders

Annex

A. Diagrams

Electrical diagrams

2. Operate and Maintenance manual (453980425021_052008_EN)

Format: PDF, 94 pages

Language: English

Table of Contents:

Summary Data for Technical Assistance

Introduction

General Information

Normative References

Areas with risk of explosion and handling of explosive loads.

Type of use and contraindications for use

Use Limitations

General Forklift Description

Equipment Assembly

Modifications to Forklift

Forklift Delivery

Safety

Safety Regulations

Placement of data plates and labels

Description of data plates and labels

Safety devices

Noise

Electromagnetic Compliance

Vibrations

General Truck View

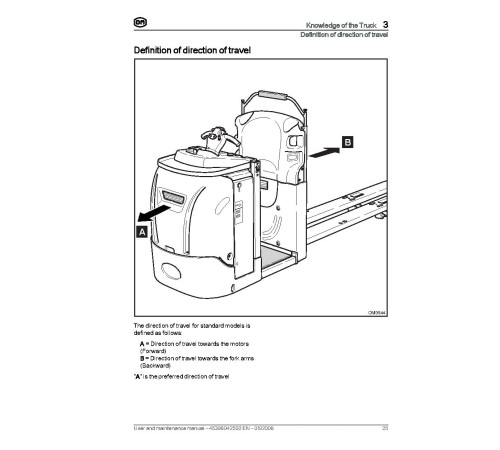

Definition of direction of travel

Knowledge of the Truck

Instrumentation and Controls

Battery cover release pushbutton

List of Available Options

Internal accessibility

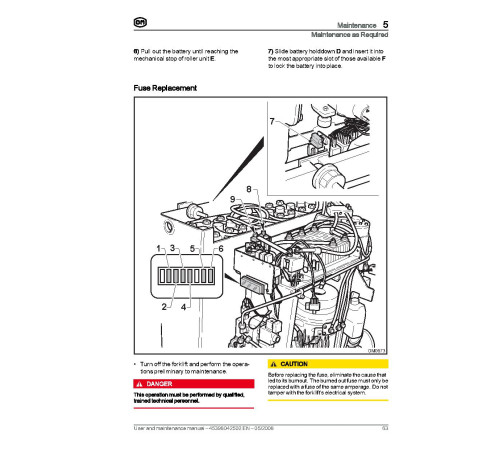

Location of Fuses

Truck Identification

Capacity rating plate

Use and Operation

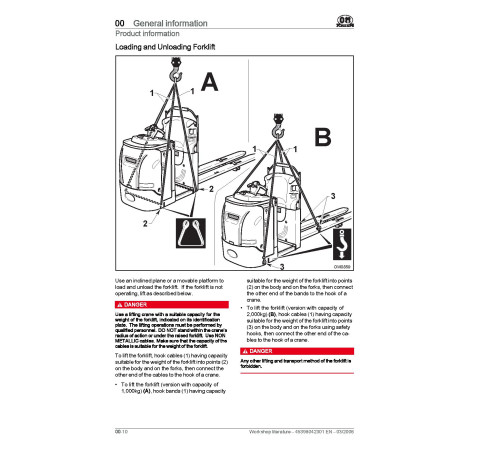

Truck Transport and Lifting

Commissioning

Breaking-In

Daily checks before use

Use of the Truck

Load Placement

Forklift Towing

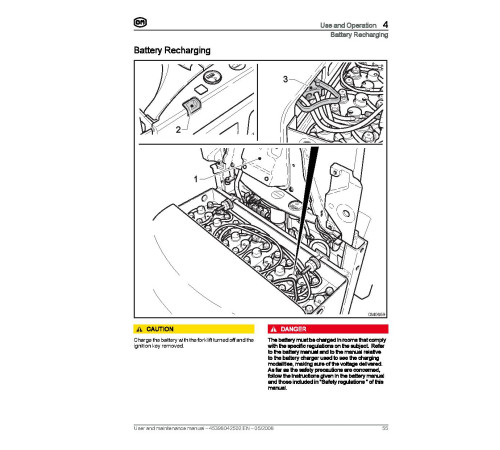

Battery Recharging

General Information

Operations Preliminary to Maintenance

Maintenance

Maintenance as Required

Scheduled Maintenance

EVERY 10 HOURS

EVERY 1000 HOURS

Putting Out of Commission

Supply Table

Resolution of Operating Defects

Overall dimensions

Technical data for XLOGO1ac

Technical data for XLOGO2ac

Battery dimensions and weights

3. Parts Catalog (373_1553403201796_en)

Format: PDF, 181 pages

Language: English

Table of Contents:

4539-4549 - XLOGO1-2 (2009-01)

CATALOGUES

CATALOGUES

ELECTRIC MOTOR

TRACTION MOTOR

GEAR DRIVE

GEAR MOTOR

REDUCTION GEAR

COVER AND PANELS-INSULATION

HOOD

FIXED FOOTBOARD SHIELD

MOBILE FOOTBOARD SHIELD

FIXED FOOTBOARD SHIELD

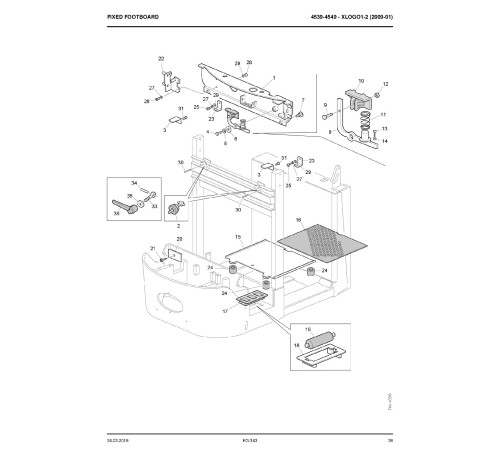

FIXED FOOTBOARD

MOBILE FOOTBOARD

STEERING SYSTEM

STEERING GEAR

TILLER ARM HEAD (FIXED FOOTBOARD)

TILLERA ARM HEAD (MOBILE FOOTBOARD)

CHASSIS

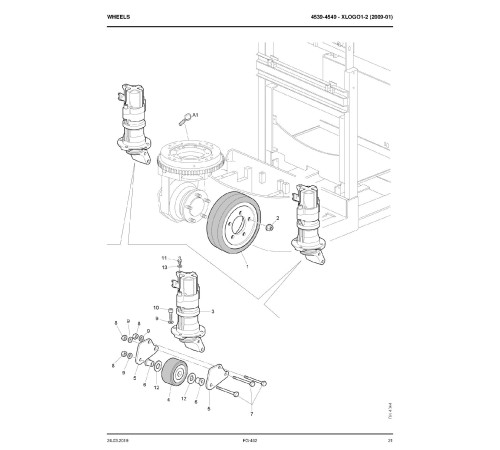

WHEELS

BRAKING SYSTEM

ELECTROMAGNETIC BRAKE

ELECTRICAL SYSTEM

ELECTRONIC PANEL

ELECTRICAL SYSTEM (PART 1)

ELECTRIC SYSTEM (PART 2)

ELECTRIC SYSTEM (PART 3)

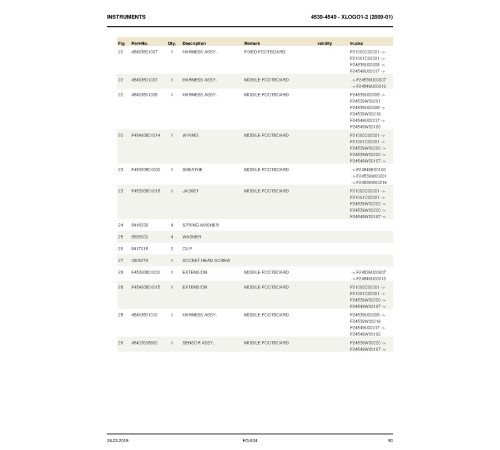

INSTRUMENTS

ELECTRONIC CONTROLS

ELECTRIC DRIVE

HYDRAULIC SYSTEM

FIXED FOOTBOARD HYDRAULIC SYSTEM (1000 Kg)

FIXED FOOTBOARD HYDRAULIC SYSTEM

MOBILE FOOTBOARD HYDRAULIC SYSTEM

SOLENOID VALVE UNIT

HYDRAULIC OPERATING SYSTEM

FIXED FOOTBOARD ELECTRIC PUMP (COP H10)

FIXED FOOTBOARD ELECTRIC PUMP (COP 20)

MOBILE FOOTBOARD ELECTRIC PUMP

LOAD LIFTING SYSTEM

MOBILE STRUCTURE (2000 Kg)

ROLLERS - TANDEM ROLLERS (2000 Kg)

MOBILE STRUCTURE (1000 Kg)

LIFT FRAME

FOOTBOARD LIFTING CYLINDER

FORK LIFTING CYLINDER (1000 Kg)

FORK LIFTING CYLINDER (2000 Kg)

OPTIONAL EQUIPMENT

SLOW SPEED PUSHBUTTON UNIT (OPTIONAL)

ONBOARD INSTRUMENTS (OPTIONAL)

READING PANEL

RECTIFIER

BATTERY EXTRACTION CARRIAGE

SHIELD (OPTIONAL)

PALLET ENTRANCE ROLLERS (OPTIONAL)

DECALS

DECALS

index parts

This manuals will assist you in diagnosing, repairing, operating, maintaining, and finding spare parts for your palet truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

XLOGO1 (4539 series)

XLOGO2 (4549 series)

The manual comprises 3 documents, including the Workshop Manual, Operate and Maintenance manual, and Parts Catalog

1. Workshop Manual (453980423011_Ed_03-06_EN)

Format: PDF, 226 pages

Language: English

Table of Contents:

General information

Product information

Safety Regulations

Technical assistance

Maintenance

Diagnostics

Connectors for diagnostics

Curtis plant diagnostics

LES electrical drive diagnostics

Motor

Drive motor

Reducer

Disassembly / Reassembly of the reducer

Reducer maintenance

Carriage

Bonnets

Steering

Electrical steering

Tiller

Wheels and lever systems

Wheels

Braking

Braking devices and methods

Service braking (eABS)

Electrical and electronic system

Electrical-electronic system in general.

Wiring

Batteries

Hydraulic system

Hydraulic diagrams

Hydraulic components

Control unit and accumulator

Lifting

Fork lifting

Platform

Cylinders

Annex

A. Diagrams

Electrical diagrams

2. Operate and Maintenance manual (453980425021_052008_EN)

Format: PDF, 94 pages

Language: English

Table of Contents:

Summary Data for Technical Assistance

Introduction

General Information

Normative References

Areas with risk of explosion and handling of explosive loads.

Type of use and contraindications for use

Use Limitations

General Forklift Description

Equipment Assembly

Modifications to Forklift

Forklift Delivery

Safety

Safety Regulations

Placement of data plates and labels

Description of data plates and labels

Safety devices

Noise

Electromagnetic Compliance

Vibrations

General Truck View

Definition of direction of travel

Knowledge of the Truck

Instrumentation and Controls

Battery cover release pushbutton

List of Available Options

Internal accessibility

Location of Fuses

Truck Identification

Capacity rating plate

Use and Operation

Truck Transport and Lifting

Commissioning

Breaking-In

Daily checks before use

Use of the Truck

Load Placement

Forklift Towing

Battery Recharging

General Information

Operations Preliminary to Maintenance

Maintenance

Maintenance as Required

Scheduled Maintenance

EVERY 10 HOURS

EVERY 1000 HOURS

Putting Out of Commission

Supply Table

Resolution of Operating Defects

Overall dimensions

Technical data for XLOGO1ac

Technical data for XLOGO2ac

Battery dimensions and weights

3. Parts Catalog (373_1553403201796_en)

Format: PDF, 181 pages

Language: English

Table of Contents:

4539-4549 - XLOGO1-2 (2009-01)

CATALOGUES

CATALOGUES

ELECTRIC MOTOR

TRACTION MOTOR

GEAR DRIVE

GEAR MOTOR

REDUCTION GEAR

COVER AND PANELS-INSULATION

HOOD

FIXED FOOTBOARD SHIELD

MOBILE FOOTBOARD SHIELD

FIXED FOOTBOARD SHIELD

FIXED FOOTBOARD

MOBILE FOOTBOARD

STEERING SYSTEM

STEERING GEAR

TILLER ARM HEAD (FIXED FOOTBOARD)

TILLERA ARM HEAD (MOBILE FOOTBOARD)

CHASSIS

WHEELS

BRAKING SYSTEM

ELECTROMAGNETIC BRAKE

ELECTRICAL SYSTEM

ELECTRONIC PANEL

ELECTRICAL SYSTEM (PART 1)

ELECTRIC SYSTEM (PART 2)

ELECTRIC SYSTEM (PART 3)

INSTRUMENTS

ELECTRONIC CONTROLS

ELECTRIC DRIVE

HYDRAULIC SYSTEM

FIXED FOOTBOARD HYDRAULIC SYSTEM (1000 Kg)

FIXED FOOTBOARD HYDRAULIC SYSTEM

MOBILE FOOTBOARD HYDRAULIC SYSTEM

SOLENOID VALVE UNIT

HYDRAULIC OPERATING SYSTEM

FIXED FOOTBOARD ELECTRIC PUMP (COP H10)

FIXED FOOTBOARD ELECTRIC PUMP (COP 20)

MOBILE FOOTBOARD ELECTRIC PUMP

LOAD LIFTING SYSTEM

MOBILE STRUCTURE (2000 Kg)

ROLLERS - TANDEM ROLLERS (2000 Kg)

MOBILE STRUCTURE (1000 Kg)

LIFT FRAME

FOOTBOARD LIFTING CYLINDER

FORK LIFTING CYLINDER (1000 Kg)

FORK LIFTING CYLINDER (2000 Kg)

OPTIONAL EQUIPMENT

SLOW SPEED PUSHBUTTON UNIT (OPTIONAL)

ONBOARD INSTRUMENTS (OPTIONAL)

READING PANEL

RECTIFIER

BATTERY EXTRACTION CARRIAGE

SHIELD (OPTIONAL)

PALLET ENTRANCE ROLLERS (OPTIONAL)

DECALS

DECALS

index parts

Included

Workshop Manual

1Operate and Maintenance manual

1Parts Catalog

1Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары