Illustrated factory set of Service Manuals for Mitsubishi Gasoline Forklift Trucks Models FGC15N (AF81F-00011-10120), FGC18N (AF81F-00011-10120), FGC20CN (AF81F-50001-60120), FGC20N (AF82F-00011-10120), FGC20N HO (AF90-00011-10120), FGC25N (AF82F-00011-10120), FGC25N HO (AF90-00011-10120), FGC28N (AF83F-00011-10120), FGC30N (AF83F-00011-10120) and FGC33N (AF83F-50001-60120).

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, and repairing engine for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FGC15N (AF81F-00011-10120)

FGC18N (AF81F-00011-10120)

FGC20CN (AF81F-50001-60120)

FGC20N (AF82F-00011-10120)

FGC20N HO (AF90-00011-10120)

FGC25N (AF82F-00011-10120)

FGC25N HO (AF90-00011-10120)

FGC28N (AF83F-00011-10120)

FGC30N (AF83F-00011-10120)

FGC33N (AF83F-50001-60120)

The manual comprises 5 documents, including the Fault Codes List, two Service Manuals, and two Engine Technical Manuals

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: Chassis, Mast, & Options (SM-99719-7C110_A06)

Format: PDF, 352 pages

Language: English

Table of Contents:

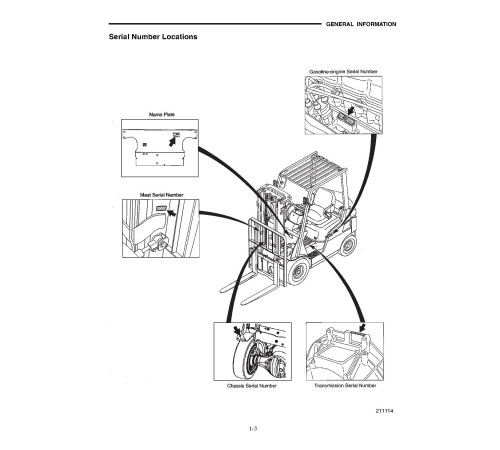

GENERAL INFORMATION

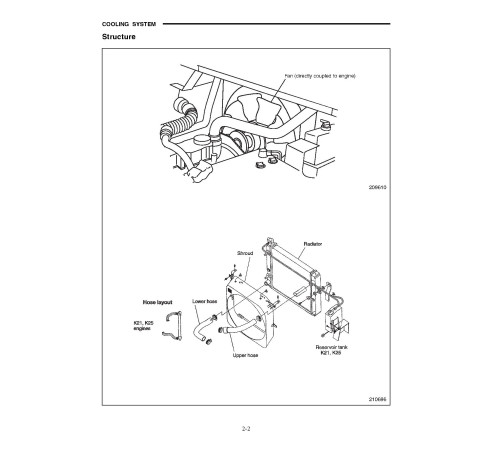

COOLING SYSTEM

ELECTRICAL SYSTEM

CONTROLERS

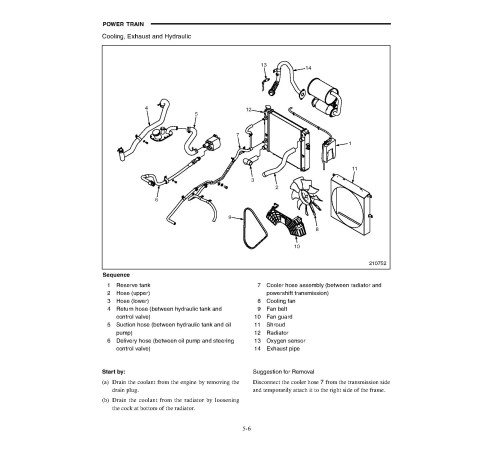

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

REDUCTION DIFFERENTIAL

SERVICE DATA

3. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

4. Engine Technical Manual: K21, K25 Engine (EN-99789-55110_K21_K25_E04)

Format: PDF, 240 pages

Language: English

Table of Contents:

FOREWORD

GROUP INDEX

GENERAL INFORMATION

MAINTENANCE

ENGINE TUNE-UP

ENGINE MECHANICAL

ENGINE CONTROL

ENGINE LUBRICATION & COOLING SYSTEMS

ENGINE FUEL

ENGINE ELECTRICAL SYSTEM

5. Engine Technical Manual: K21, K25 Engine (EN-99789-55101_K21-K25_A08)

Format: PDF, 232 pages

Language: English

Table of Contents:

How to use this manual

Description

Definition of Terms

Definition of Units

Description

Precautions for safety and quality

Reduction of Risk Operation

Correct Operation

Precautions for Radio Equipment Installation

Precautions

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Special Service Tools

Engine outside drawings

Standard and repair limit

Trouble diagnosis

Engine Adjustment

Engine LPG Fuel System

Engine maintenance

Specifications

Tightening Torque

Maintenance Schedule

Oil and Grease, and Capacity

On Board Inspection and Service

Specifications

Tightening torque

Trouble diagnosis

ENGINE INSPECTION AND ADJUSTMENT

Engine Body Related

Ignition and Fuel Systems

SERVICE DATA AND SPECI FICATIONS (SDS)

Electronic Control System Specifications

Precautions

Precautions for Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Engine outside drawings

Adjustment value

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Trouble diagnosis

Special Service Tools

Removal and installation of engine

Removal

Installation

Inspection

Engine service

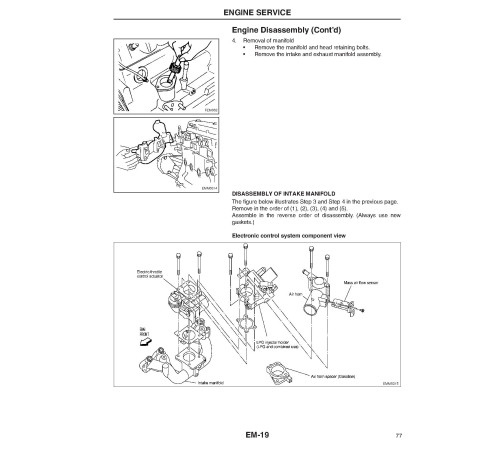

Engine Disassembly

Inspection and Correction

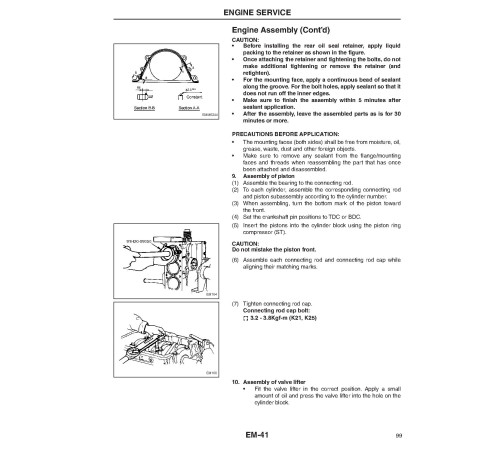

Engine Assembly

Precautions

General precautions for service operations

Preparation

Service Tools

Description

Basic inspection

Inspection of Idle Speed, Ignition Timing, and Air-fuel Ratio

Throttle Valve Closed Position Learning and Idle Air Volume Learning

Accelerator Pedal Released Position Learning

Fuel pressure inspection

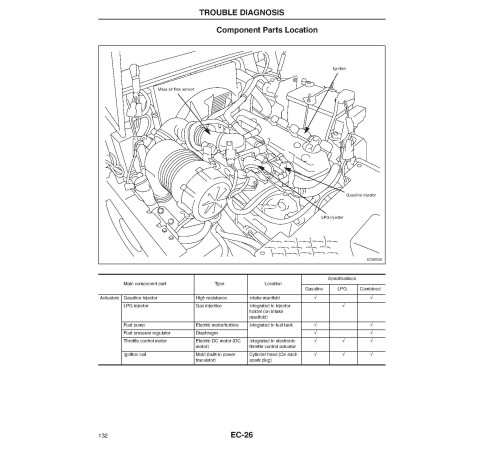

Trouble Diagnosis

How to Proceed with Trouble Diagnosis

Diagnosis Chart by Symptom

Component Parts Location

ECM Component

Circuit Diagram

ECM Terminal Layout

ECM Input/Output Signal Specifications

Service Tool (ST)

Self-Diagnosis Function (without ST)

ST Reference Value in Data Monitor

Fail-Safe Function

Power supply and ground system

ECM Input/Output Signal Specifications

Circuit Diagram

Crankshaft position sensor (POS) sys tem

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Camshaft position sen sor (PHASE) system

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Mass air flow sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Engine coolant tempera ture sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Heated oxygen sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Throttle position sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Accelerator pedal position sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Intake air temperature sensor

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

PNP switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Stop lamp switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Electric load switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

CAN communication system

ECM Input/Output Signal Specifications

Circuit Diagram

Ignition system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Fuel injector system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Fuel pump system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Throttle control motor system

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Heated oxygen sensor heater system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

PCV gas recirculation device

System Diagram

Component Parts Inspection

Fuel cut function

Inspection Procedure

Removal and installation of ECM components

Removal and Installation of ECM

Removal and Installation of Crankshaft Position Sensor (POS)

Removal and Installation of Camshaft Position Sensor (PHASE)

Removal and Installation of Mass Air Flow Sensor

Removal and Installation of Engine Coolant Temperature Sensor.

Removal and Installation of Heated Oxygen Sensor (with Heated Oxygen Sensor Heater)

Removal and Installation of Throttle Position Sensor (Electric Throttle Control Actuator Assembly)

Removal and Installation of Accelerator Pedal Position Sensor (Accelerator Pedal Assembly)

Removal and Installation of Intake Air Temperature Sensor (with Mass Air Flow Sensor)

Removal and Installation of Neutral Switch (M/T Model)

Removal and Installation of Ignition Coil (with Power Transistor)

Removal and Installation of Fuel Injector

Removal and Installation of Fuel Pump

Removal and Installation of Throttle Control Motor (Electric Throttle Control Actuator Assembly)

Removal and Installation of LPG Injector Holder

Removal and Installation of LPG Injector Drive Unit

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard, Repair Limit

Lubrication system

Specifications

Adjustment Value

Oil Pressure

Tightening Torque

Trouble Diagnosis

Lubrication Schematic Diagram

Oil Pump

Engine coolant system

Specifications

Adjustment Value

Tightening Torque

Trouble Diagnosis

Cooling System Configuration

Water Pump

Thermostat

Thermostat

Emission control system (only for electronic controlled type)

Unit layout

LPG fuel system trouble diagnosis

Disassembly and assembly of fuel system

Removal and Installation of LPG Injector Drive Unit Connector

Removal and Installation of Electronic Control Throttle Assembly

Removal and Installation of Gasoline Fuel Injector (Electronic Controlled Gasoline and Combined Use)

Injector Holder

Vaporizer mechanism and operation

Primary (Decompression) Room

Description

Adjustment value

Trouble diagnosis

Starter motor

Starter Motor Specifications

Component Parts Location

Overhaul

Assembly Inspection

Alternator

Components of Alternator

Disassembly

Inspection

This manuals will assist you in determining a malfunction using a fault code, diagnosing, analyses, testing, repair, and repairing engine for your gasoline forklift truck.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

FGC15N (AF81F-00011-10120)

FGC18N (AF81F-00011-10120)

FGC20CN (AF81F-50001-60120)

FGC20N (AF82F-00011-10120)

FGC20N HO (AF90-00011-10120)

FGC25N (AF82F-00011-10120)

FGC25N HO (AF90-00011-10120)

FGC28N (AF83F-00011-10120)

FGC30N (AF83F-00011-10120)

FGC33N (AF83F-50001-60120)

The manual comprises 5 documents, including the Fault Codes List, two Service Manuals, and two Engine Technical Manuals

1. Fault Codes List (REF-18-0008M_69904)

Format: PDF, 13 pages

Language: English

2. Service Manual: Chassis, Mast, & Options (SM-99719-7C110_A06)

Format: PDF, 352 pages

Language: English

Table of Contents:

GENERAL INFORMATION

COOLING SYSTEM

ELECTRICAL SYSTEM

CONTROLERS

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

REDUCTION DIFFERENTIAL

SERVICE DATA

3. Service Manual: 35DV/45DV/55DV-MQ Mast (SM-LTI-263920-Mast)

Format: PDF, 48 pages

Language: English

4. Engine Technical Manual: K21, K25 Engine (EN-99789-55110_K21_K25_E04)

Format: PDF, 240 pages

Language: English

Table of Contents:

FOREWORD

GROUP INDEX

GENERAL INFORMATION

MAINTENANCE

ENGINE TUNE-UP

ENGINE MECHANICAL

ENGINE CONTROL

ENGINE LUBRICATION & COOLING SYSTEMS

ENGINE FUEL

ENGINE ELECTRICAL SYSTEM

5. Engine Technical Manual: K21, K25 Engine (EN-99789-55101_K21-K25_A08)

Format: PDF, 232 pages

Language: English

Table of Contents:

How to use this manual

Description

Definition of Terms

Definition of Units

Description

Precautions for safety and quality

Reduction of Risk Operation

Correct Operation

Precautions for Radio Equipment Installation

Precautions

Precautions in Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Special Service Tools

Engine outside drawings

Standard and repair limit

Trouble diagnosis

Engine Adjustment

Engine LPG Fuel System

Engine maintenance

Specifications

Tightening Torque

Maintenance Schedule

Oil and Grease, and Capacity

On Board Inspection and Service

Specifications

Tightening torque

Trouble diagnosis

ENGINE INSPECTION AND ADJUSTMENT

Engine Body Related

Ignition and Fuel Systems

SERVICE DATA AND SPECI FICATIONS (SDS)

Electronic Control System Specifications

Precautions

Precautions for Draining Engine Coolant

Precautions for Disconnecting Fuel Piping

Precautions for Removing and Disassembling

Precautions for Inspection, Correction, and Replacement

Precautions for Assembly and Installation

Parts Requiring Angle Tightening

Caution for Use of Power Tools

Precautions for Liquid Gasket Application

Engine outside drawings

Adjustment value

Tightening torque

Standard Bolt Tightening Torque

Engine Part Tightening Torque

Trouble diagnosis

Special Service Tools

Removal and installation of engine

Removal

Installation

Inspection

Engine service

Engine Disassembly

Inspection and Correction

Engine Assembly

Precautions

General precautions for service operations

Preparation

Service Tools

Description

Basic inspection

Inspection of Idle Speed, Ignition Timing, and Air-fuel Ratio

Throttle Valve Closed Position Learning and Idle Air Volume Learning

Accelerator Pedal Released Position Learning

Fuel pressure inspection

Trouble Diagnosis

How to Proceed with Trouble Diagnosis

Diagnosis Chart by Symptom

Component Parts Location

ECM Component

Circuit Diagram

ECM Terminal Layout

ECM Input/Output Signal Specifications

Service Tool (ST)

Self-Diagnosis Function (without ST)

ST Reference Value in Data Monitor

Fail-Safe Function

Power supply and ground system

ECM Input/Output Signal Specifications

Circuit Diagram

Crankshaft position sensor (POS) sys tem

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Camshaft position sen sor (PHASE) system

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Mass air flow sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Engine coolant tempera ture sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Heated oxygen sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Throttle position sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Accelerator pedal position sensor system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Intake air temperature sensor

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

PNP switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Stop lamp switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Electric load switch system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

CAN communication system

ECM Input/Output Signal Specifications

Circuit Diagram

Ignition system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Fuel injector system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Fuel pump system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Throttle control motor system

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

Heated oxygen sensor heater system

ST Data Monitor Display

ECM Input/Output Signal Specifications

Circuit Diagram

Component Parts Inspection

PCV gas recirculation device

System Diagram

Component Parts Inspection

Fuel cut function

Inspection Procedure

Removal and installation of ECM components

Removal and Installation of ECM

Removal and Installation of Crankshaft Position Sensor (POS)

Removal and Installation of Camshaft Position Sensor (PHASE)

Removal and Installation of Mass Air Flow Sensor

Removal and Installation of Engine Coolant Temperature Sensor.

Removal and Installation of Heated Oxygen Sensor (with Heated Oxygen Sensor Heater)

Removal and Installation of Throttle Position Sensor (Electric Throttle Control Actuator Assembly)

Removal and Installation of Accelerator Pedal Position Sensor (Accelerator Pedal Assembly)

Removal and Installation of Intake Air Temperature Sensor (with Mass Air Flow Sensor)

Removal and Installation of Neutral Switch (M/T Model)

Removal and Installation of Ignition Coil (with Power Transistor)

Removal and Installation of Fuel Injector

Removal and Installation of Fuel Pump

Removal and Installation of Throttle Control Motor (Electric Throttle Control Actuator Assembly)

Removal and Installation of LPG Injector Holder

Removal and Installation of LPG Injector Drive Unit

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard, Repair Limit

Lubrication system

Specifications

Adjustment Value

Oil Pressure

Tightening Torque

Trouble Diagnosis

Lubrication Schematic Diagram

Oil Pump

Engine coolant system

Specifications

Adjustment Value

Tightening Torque

Trouble Diagnosis

Cooling System Configuration

Water Pump

Thermostat

Thermostat

Emission control system (only for electronic controlled type)

Unit layout

LPG fuel system trouble diagnosis

Disassembly and assembly of fuel system

Removal and Installation of LPG Injector Drive Unit Connector

Removal and Installation of Electronic Control Throttle Assembly

Removal and Installation of Gasoline Fuel Injector (Electronic Controlled Gasoline and Combined Use)

Injector Holder

Vaporizer mechanism and operation

Primary (Decompression) Room

Description

Adjustment value

Trouble diagnosis

Starter motor

Starter Motor Specifications

Component Parts Location

Overhaul

Assembly Inspection

Alternator

Components of Alternator

Disassembly

Inspection

Included

Fault Codes List

1Service Manual

2Engine Technical Manual

2Reviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Похожие товары